Double-regulating electric combined device and method of Kaplan turbine

A technology of dual adjustment and associated devices, applied in hydropower, safety devices, mechanical equipment, etc., can solve the problems of reduced unit flow, reduced unit stability, and reduced guide vane opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

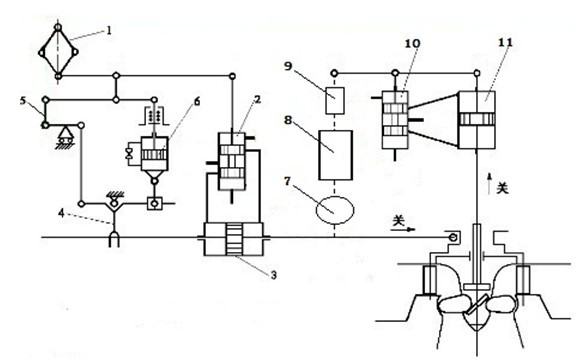

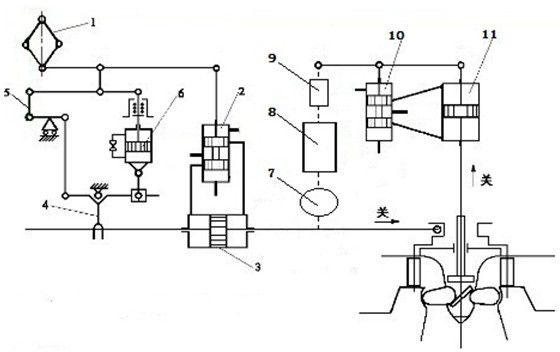

[0017] like figure 1 As shown, the water turbine is connected to the centrifugal pendulum 1 through a synchronous mechanism, and the rotational speed of the unit is synchronously sensed by the centrifugal pendulum 1. The centrifugal pendulum 1 is connected to the guide vane pressure distribution valve 2 through a lever mechanism, and the guide vane pressure distribution valve 2 is connected to the guide vane servomotor. 3. The oil circuit is connected to control the opening or closing or stopping of the guide vane servomotor 3 through the oil circuit. The guide vane servomotor 3 is used to control the opening of the movable guide vane, and a feedback unit is connected between the guide vane servomotor 3 and the synchronous mechanism; at the same time, the guide vane servomotor 3 is connected sequentially through the displacement sensor 7, the processing unit 8, The electrical association formed by the hydraulic conversion mechanism 9 is electrically connected to the vane press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com