Transmission device for capping machine

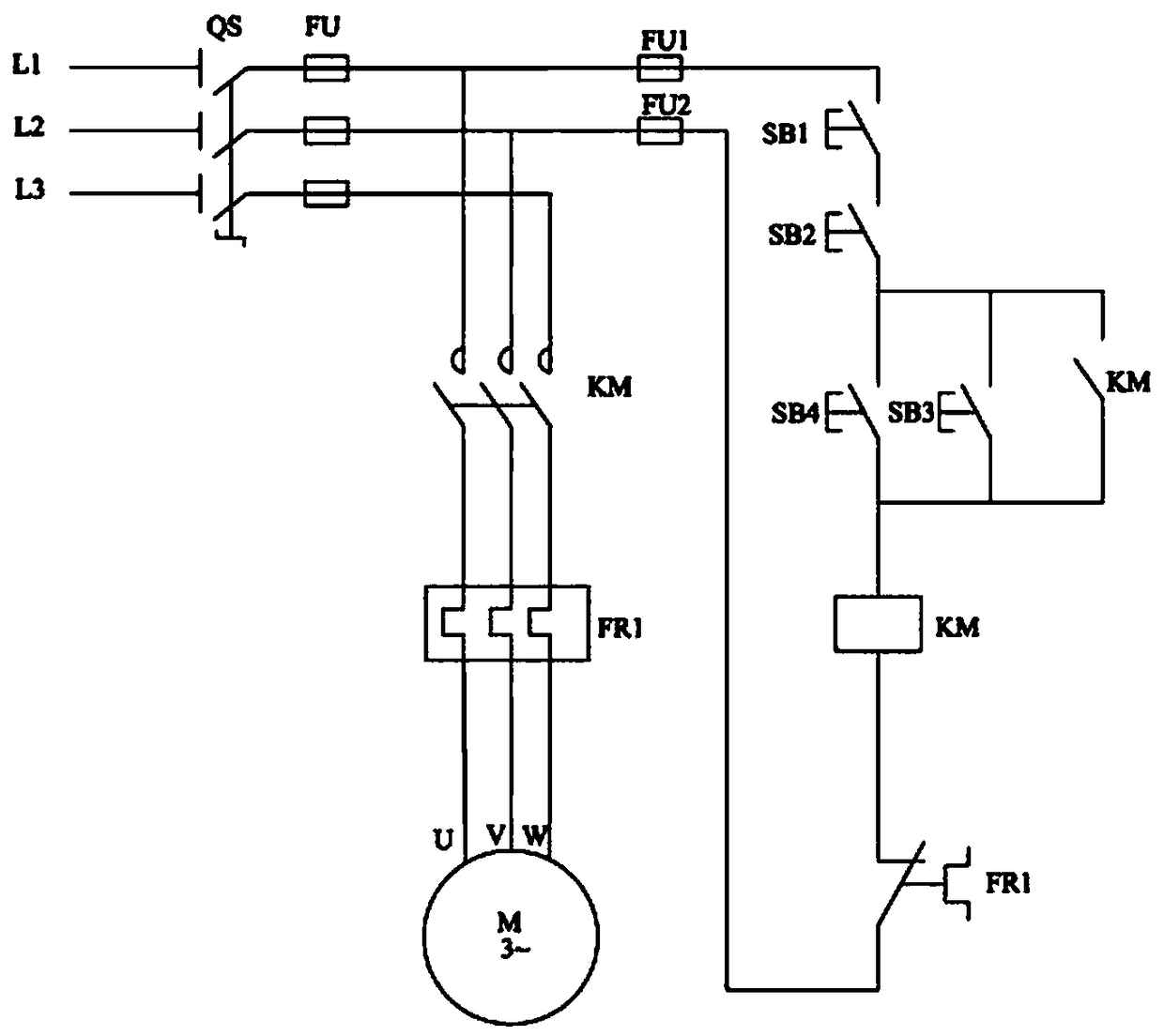

A technology of conveying device and capping machine, which is used in conveyor control device, transportation and packaging, conveyor and other directions, can solve problems such as bottle dumping, potential safety hazards for equipment and operators, and non-compliance with electrical safety regulations when pulling gates with load. , to achieve the effect of convenient shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

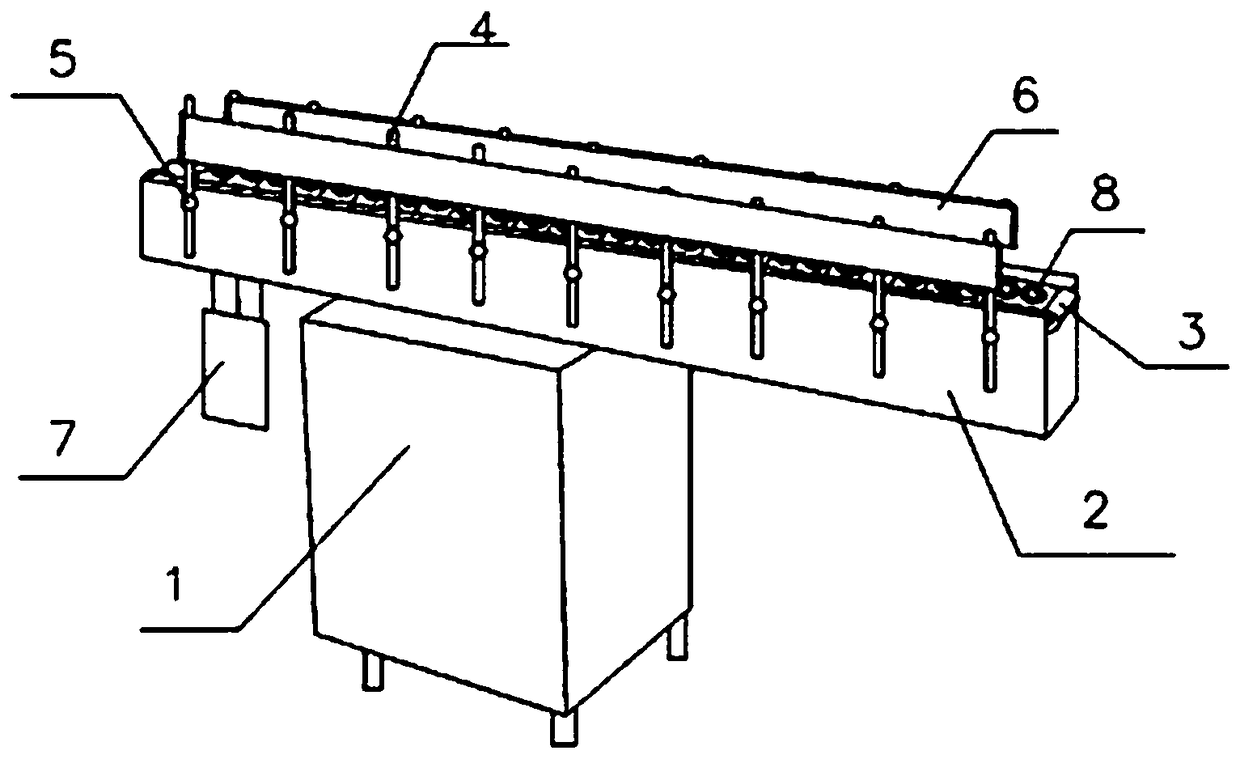

[0014] according to Figure 1~2 The specific structure of the present invention will be described in detail. The transmission device used by this capping machine includes a support 1, a conveyor 2, a positioning conveyor belt 3, and a guide bar 4, wherein the conveyor 2 is fixed on the support 1, and the guide bar 4 is located on both sides of the conveyor 2, and the positioning conveyor belt 3 is spaced apart. There is a positioning groove 8, and the entire positioning conveyor belt 3 is made of plastic, which is directly set on the conveyor belt of the conveyor 2, which is convenient for disassembly. The conveyor 2 is driven by the driver 7, and the size of the positioning groove 8 can be adjusted according to the size of the bottom of the bottle. Formulate; the both sides of conveyor 2 are provided with fixed rods 5 at intervals, and guide bar 4 is fixed on the fixed rods 5 on both sides of conveyor 1 by bolts, and the position can be adjusted forward and backward according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com