Combined adjusting method of water turbine

A technology of synergetic adjustment and water turbine, which is applied in the direction of mechanical equipment, hydropower generation, engine components, etc., can solve the problems of unit flow reduction, unit stability reduction, shutdown and transition time reduction, etc., to increase braking torque and improve Stability and time-shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

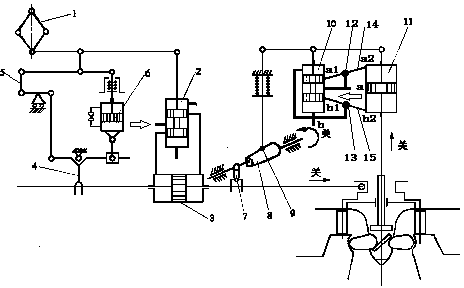

[0019] like figure 1 As shown, the first three-way valve 12 is connected to the first oil pipe 14 between the vane pressure distribution valve 10 and the vane servomotor 11, and the second oil pipe 15 between the vane pressure distribution valve 10 and the vane servomotor 11 is connected to The second three-way valve 13.

[0020] The a1 end of the vane pressure distribution valve 10 is connected to the first port of the first three-way valve 12, the a2 end of the vane servomotor 11 is connected to the second port of the first three-way valve 12, and the a end of the vane pressure distribution valve 10 is connected to the first port of the first three-way valve 12. The third way of the three-way valve 12.

[0021] The b1 end of the vane pressure distribution valve 10 is connected to the first port of the second three-way valve 13, the b2 end of the vane servomotor 11 is connected to the second port of the second three-way valve 13, and the b end of the vane pressure distributi...

Embodiment 2

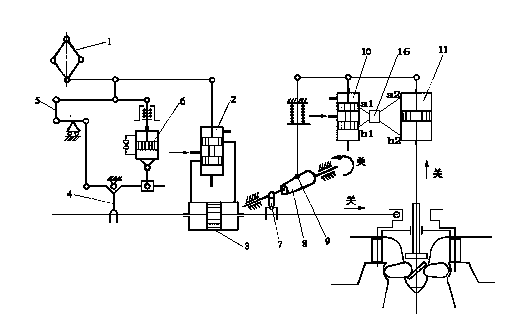

[0029] like image 3 As shown, the four-way reversing valve 16 is connected between the vane pressure distribution valve 10 and the vane servomotor 11. The a2 end and b2 end of the four-way reversing valve 16 are respectively connected to the other two ports of the four-way reversing valve 16, and the four-way reversing valve 16 controls the valve plate of the four-way reversing valve 16 to switch, so that the a1 end of the vane pressure distribution valve 10 and the vane The b2 end of the servomotor 11 communicates, so that the b1 end of the vane pressure distribution valve 10 communicates with the a2 of the vane servomotor 11; it can also be switched to make the a1 end of the vane pressure distribution valve 10 communicate with the a2 of the vane servomotor 11, so that the vane The b1 end of the pressure distribution valve 10 communicates with the b2 end of the vane servomotor 11 .

[0030] The a1 end and b1 end of the vane pressure distribution valve 10 and the a2 end and b2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com