Method for measuring uniformity and synchronism of blade opening

A measurement method and synchronous technology, applied in the direction of measurement device, inclination measurement, mapping and navigation, etc., can solve the risk of slipping, mechanical injury and even high-altitude falling, operators in slipping, high-altitude work, propeller blades Due to the inaccurate characterization of the synchronism of the opening degree, the effects of obvious data post-processing and analysis capabilities, convenient device layout and connection establishment, and rapid graph generation are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

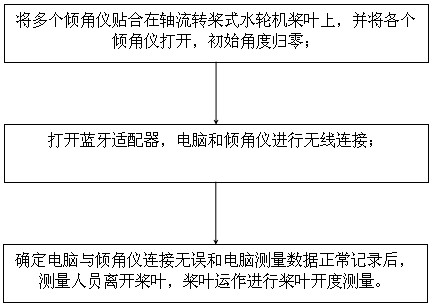

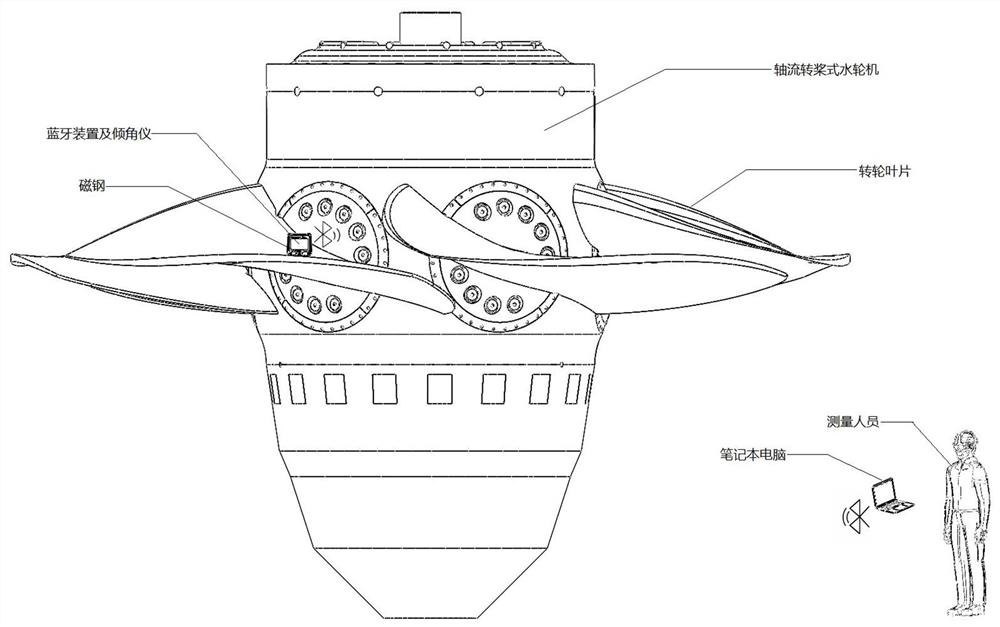

Method used

Image

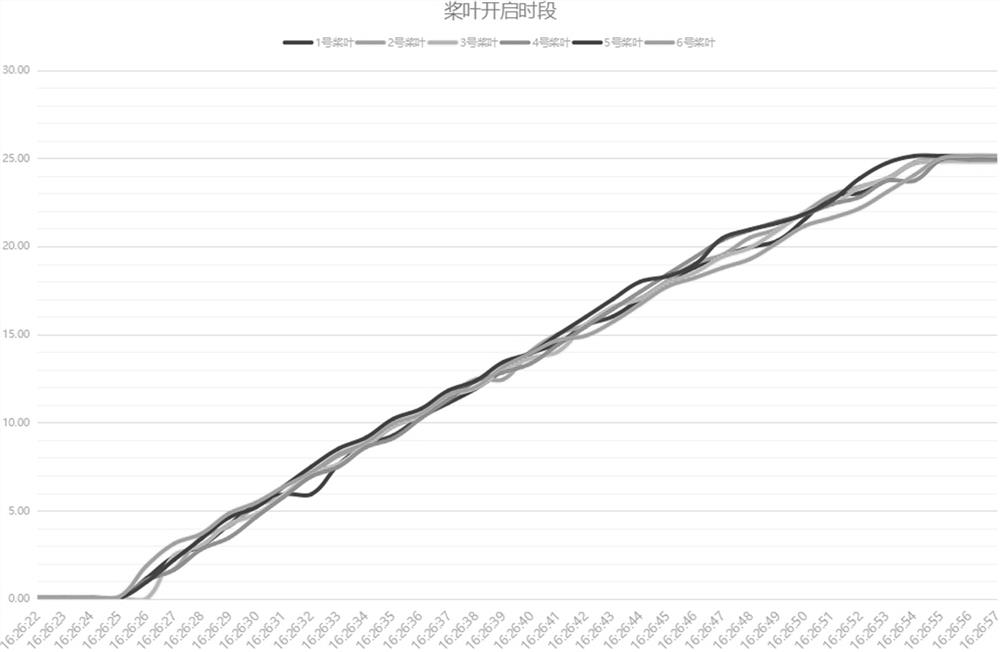

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show the structural components related to the present invention, but not the entire structural structure.

[0040] At present, the measurement of blade opening has the following problems:

[0041] (1) During the measurement process, the measurement personnel are located on the inner side of the seat ring or between the movable guide vanes to observe and record, and the risk of slipping, mechanical injury and even falling from high altitudes is high;

[0042] (2) The measurement results are inaccurate and the error is large due to factors such as manual observation and recording, and inaccurate rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com