Mounting structure for carburetor needle valve

An installation structure and carburetor technology, applied in carburetors, charging systems, machines/engines, etc., can solve problems such as high fuel consumption, unstable fuel supply, and affecting engine stability, so as to reduce fuel consumption and improve fuel supply Stable, smooth connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

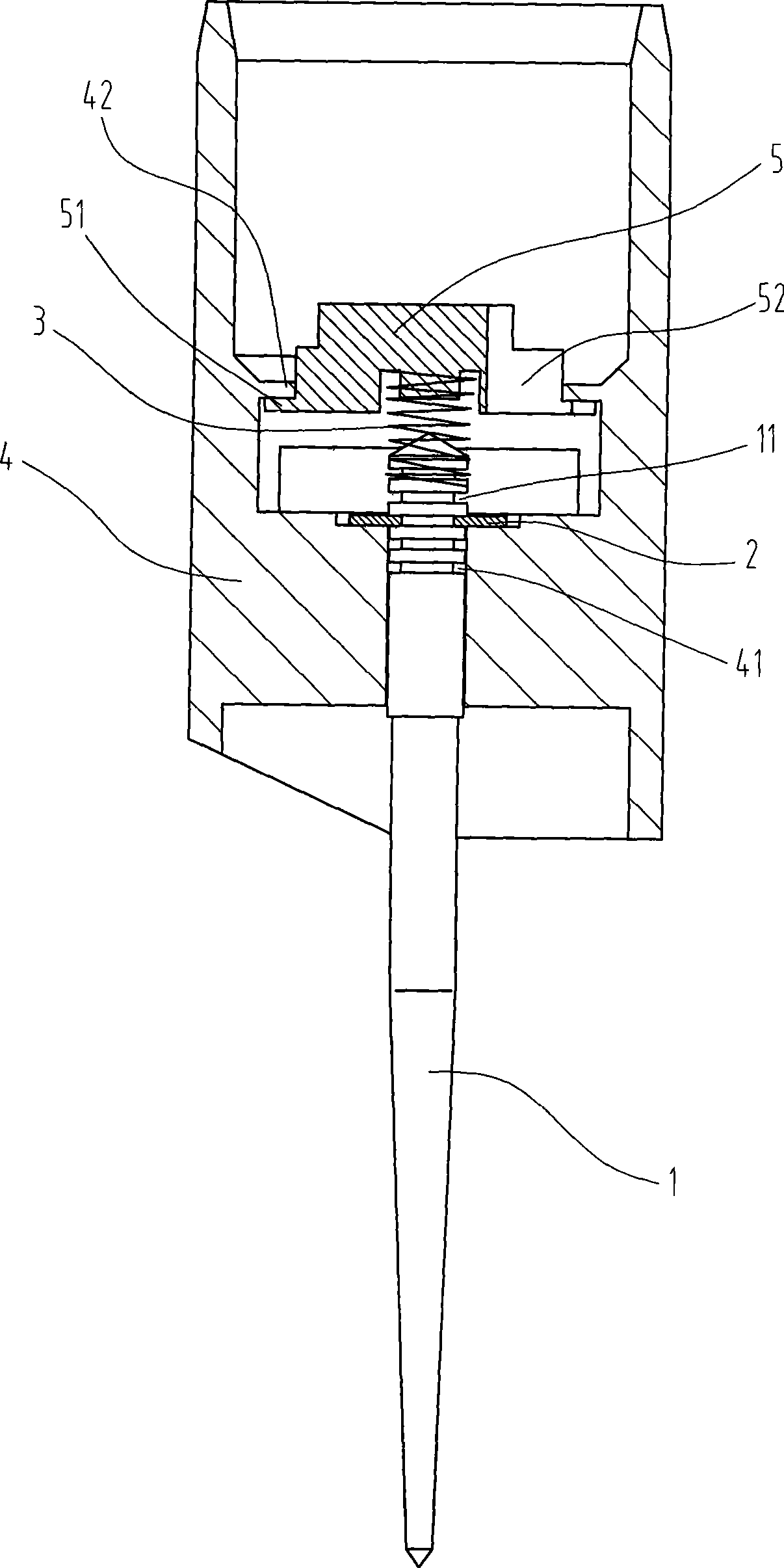

[0013] Such as figure 1 As shown, a carburetor oil needle installation structure is mainly used on a motorcycle flat-suction plunger carburetor. One end of the oil needle 1 is provided with a groove 11, and the other end is tapered, and the groove 11 is Clamp 2 is installed, one end of oil needle 1 with groove 11 is covered with spring 3, oil needle 1 passes through oil needle hole 41 at the bottom of plunger 4 and is limited by clamp 2, and one end of spring 3 rests on On the fixed frame 5 , the fixed frame 5 is limited by the boss 42 on the inner wall of the plunger 4 .

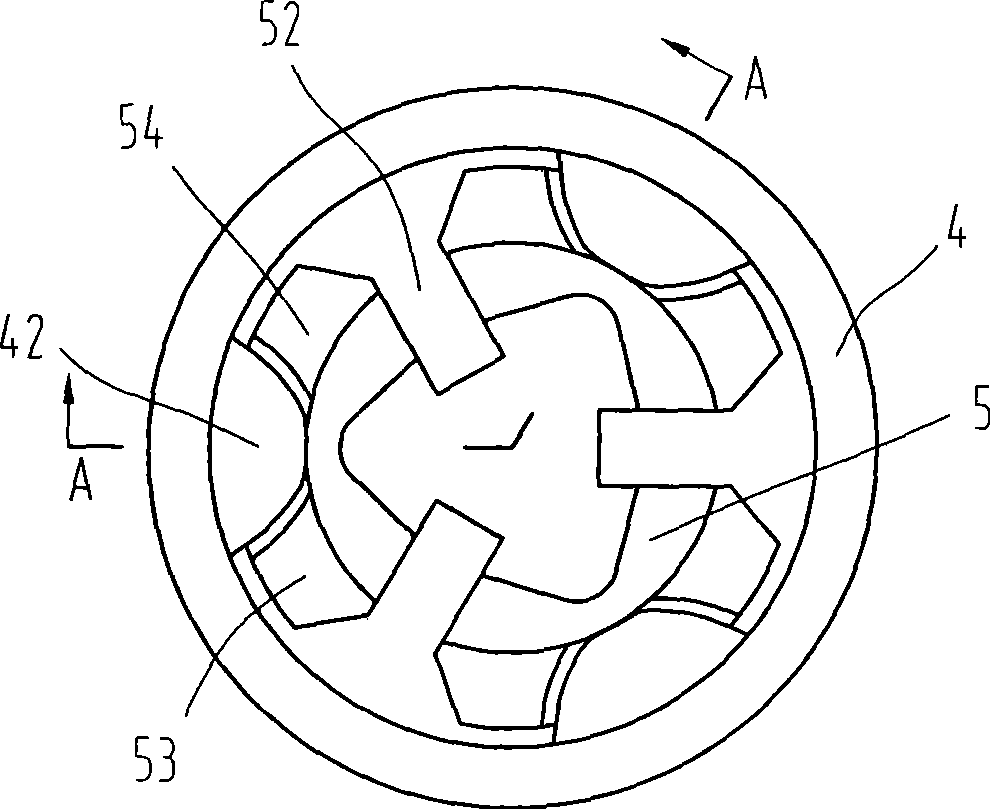

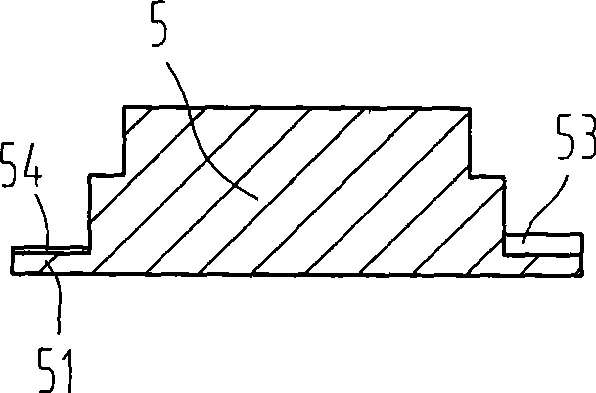

[0014] Such as figure 1 , figure 2 and image 3 As shown, the fixed frame 5 is tower-shaped, and there are three bosses 42 on the inner wall of the plunger 4 and are evenly distributed in the circumferential direction. Three longitudinal grooves 52 are evenly distributed in the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com