Walking dual-swing downhole drill

A down-the-hole drilling rig and walking-type technology, which is applied in the field of walking-type double-circle down-the-hole drilling rigs, can solve the problems of large water resource consumption, low working efficiency, incompatibility, etc., and achieve the effects of simple structure, high working efficiency and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

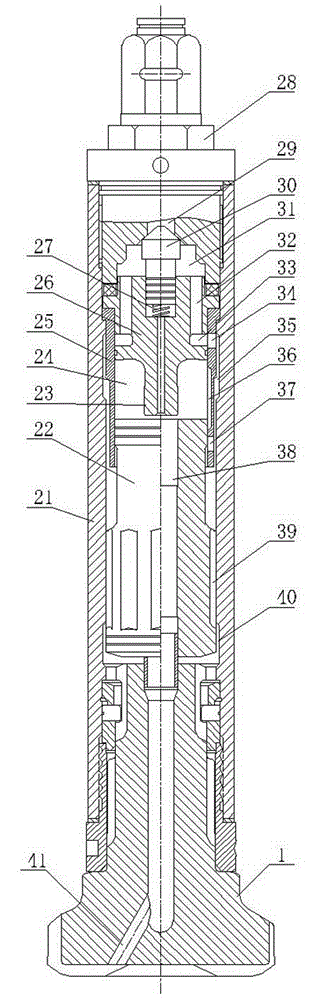

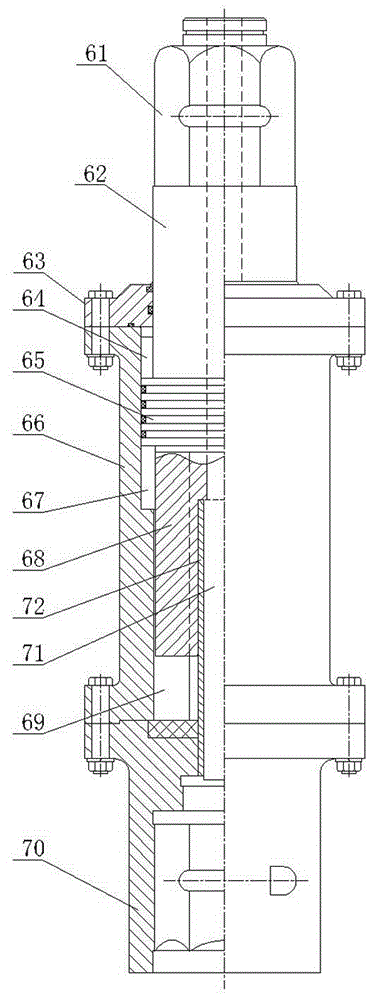

[0019] The relevant details and working principles of specific embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

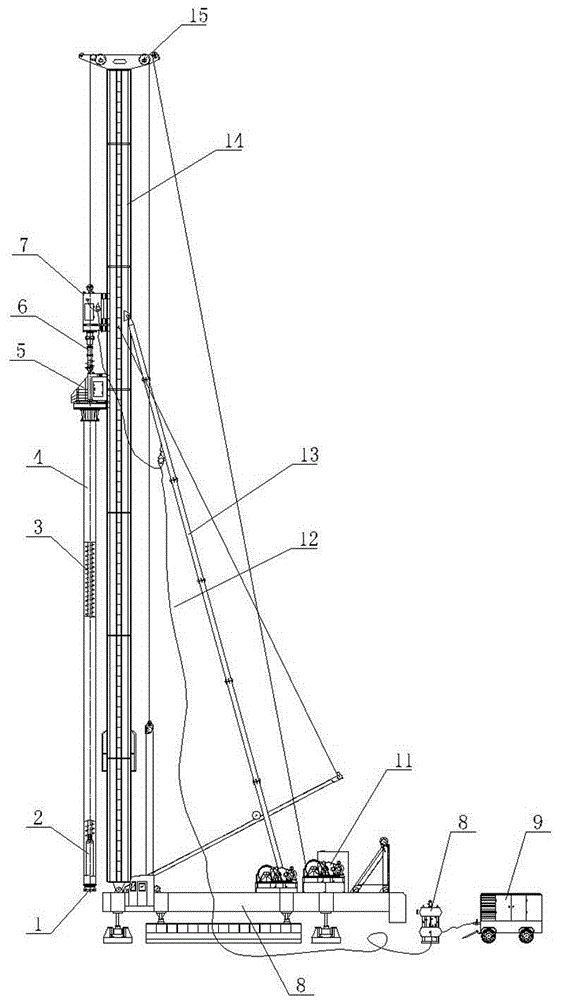

[0020] Such as figure 1 As shown, the walking double-rotating down-the-hole drilling rig of the present invention includes a pile frame main body, a drilling main body, an oil mist generator 8 and an air compressor 1, and the pile frame main body includes a walking chassis 10, a column 14, and a diagonal bracing mechanism 13 , hoist 11 and pulley block 15, the drilling main body includes upper power head 7, lower power head 5, outer casing 4, auger rod 3 and down-the-hole hammer (composed of impactor 2 and impact hammer 1), and upper power head 7 passes through The buffer 6 is connected with the top of the auger rod 3, the auger rod 3 moves through the inner hole provided by the lower power head 5 and the outer casing 4, the bottom end of the auger rod 3 is connected with the down-the-hole hammer, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com