In-process sintering machine trolley wheel automatic centering device

An automatic centering and sintering machine technology, applied in crucible furnaces, furnaces, lighting and heating equipment, etc., can solve problems such as increasing personnel overhead, shortening bearing service life, affecting material balance, etc., to improve resource utilization and reduce personnel. Cost, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

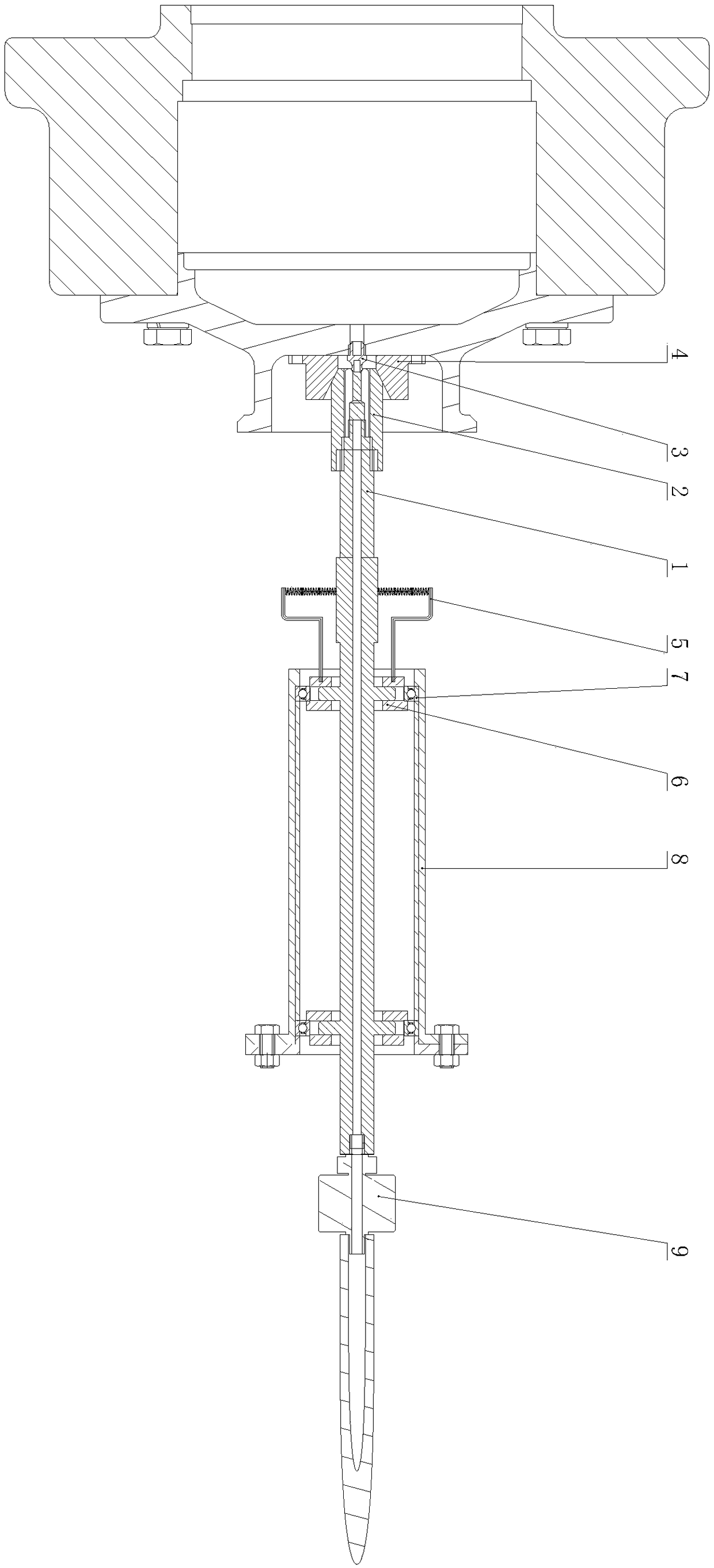

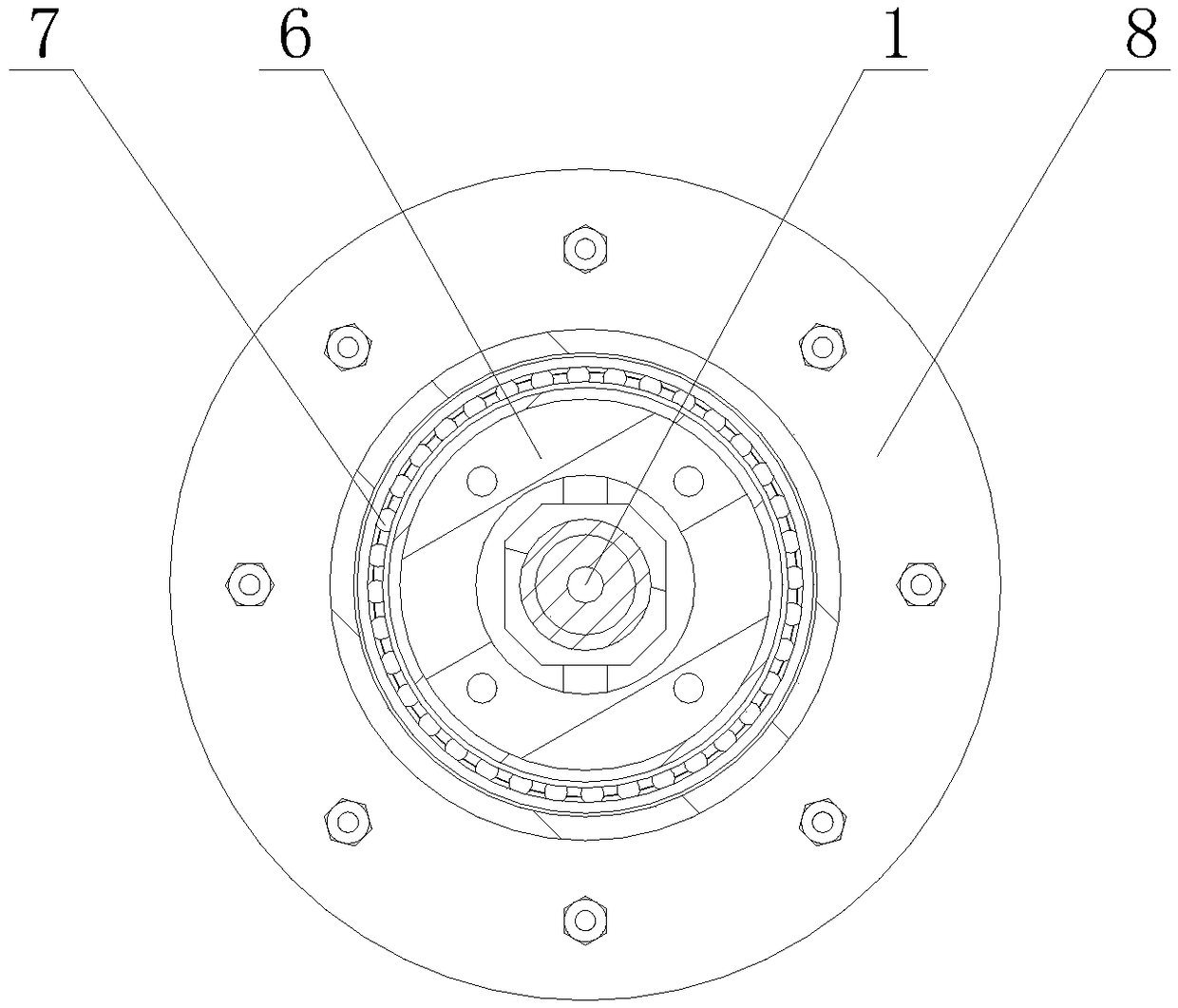

[0021] from figure 1 It can be seen that the automatic wheel centering device of a moving sintering machine in this embodiment includes a rotary shaft 1, one end of the rotary shaft 1 is provided with a shaft end joint body 2, and the front end of the shaft end joint body 2 is provided with a wheel. The outer surface of the wheel is respectively fixed with the wheel joint body 3 and the wheel positioning block 4, the shaft end joint body 2 and the wheel joint body 3 cooperate with each other, and the wheel positioning block 4 is used for guiding. direction and moving towards the wheel, under the guidance of the positioning block 4 on the wheel, the shaft end joint body 2 at the front end of the rotary shaft 1 and the wheel joint body 3 located on the wheel perform mutual sealing cooperation, and the shaft end joint body 2 can To adapt to the direction deviation of the wheel, ensure that the lubricating grease can be injected into the inside of the wheel under pressure. The oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com