Excavator movable arm energy-saving system

A technology of energy-saving system and motorized arm, which is applied to fluid pressure actuating system components, mechanically driven excavators/dredgers, earthmoving machines/shovels, etc., which can solve the problem of reduced practicability, high cost, and overall energy-saving system. high cost problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

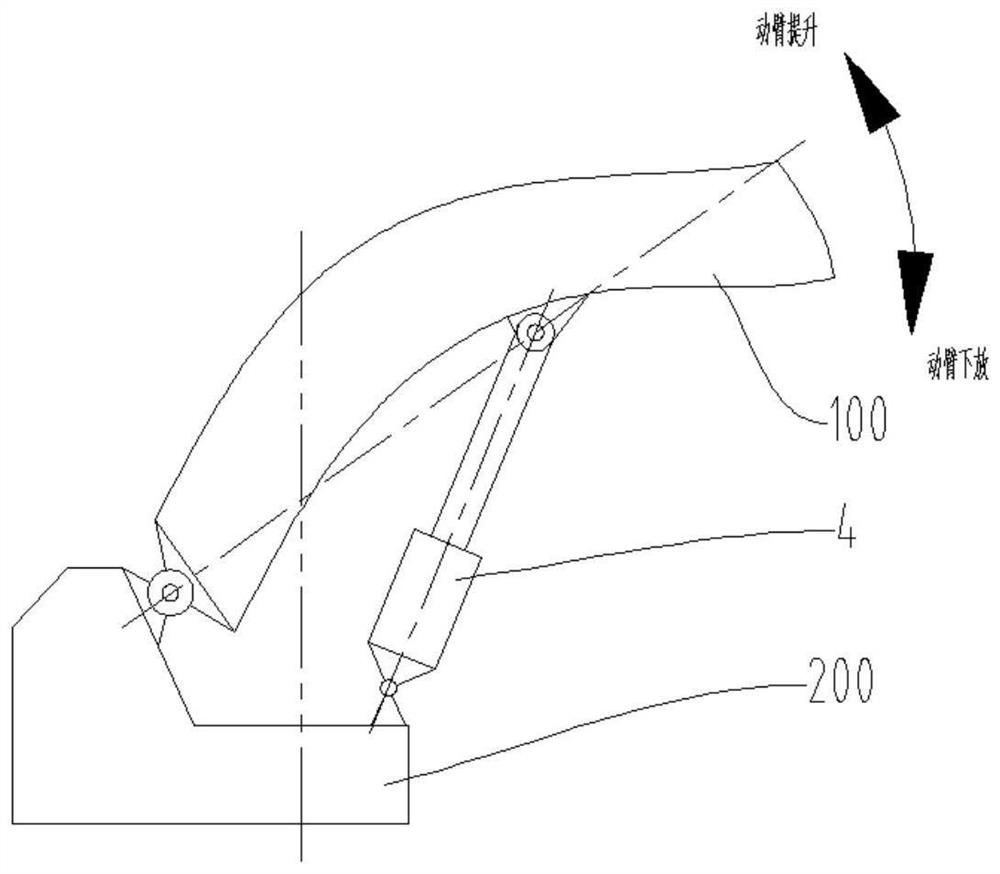

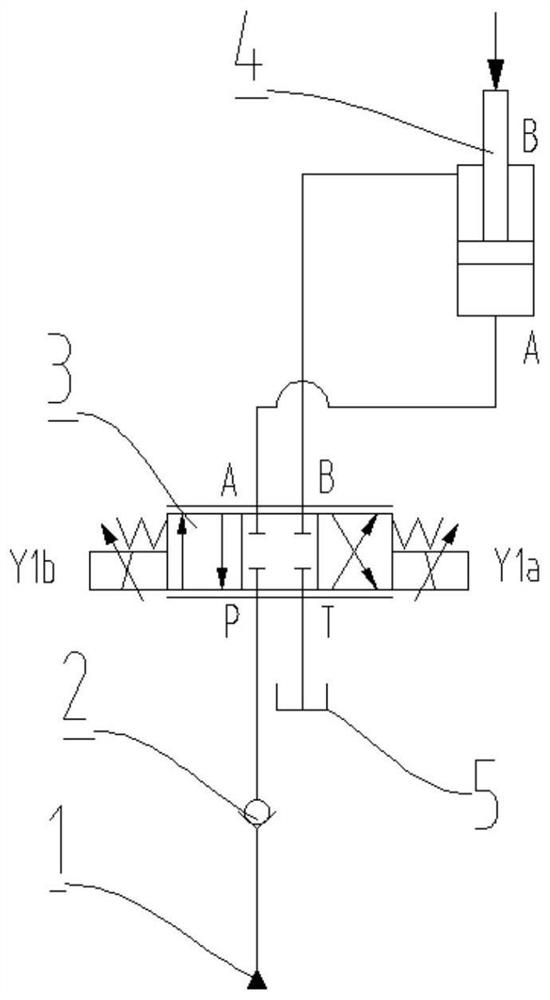

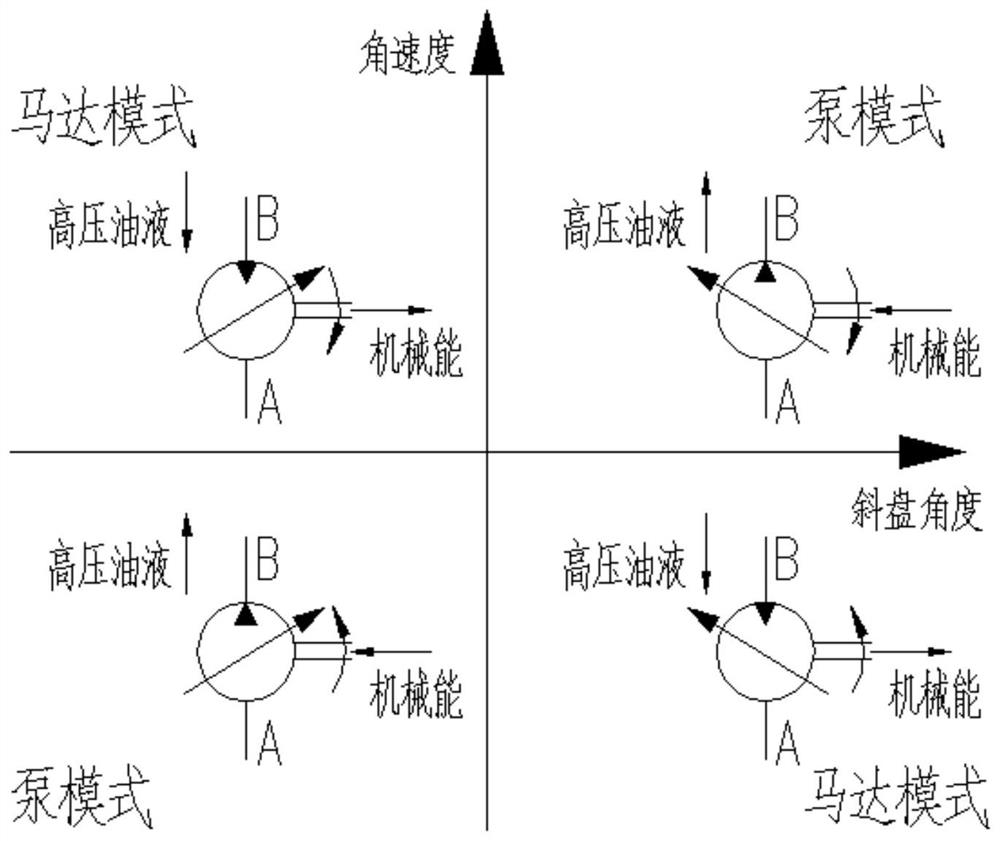

[0052] Such as Figure 4 , Figure 6 and Figure 7 As shown, an excavator arm energy-saving system includes an oil source 1, a first one-way valve 2, a main reversing valve 3, a boom hydraulic cylinder 4, a joystick of an excavator, a fifth one-way valve 17, a hydraulic pressure Motor 6, accumulator 10, gearbox 8, first reversing valve 11, clutch 9, flywheel 7, second one-way valve 13, third one-way valve 14, fourth one-way valve 16, speed detection device and Controller; the oil source 1 is connected to the P port of the main reversing valve 3 through the first one-way valve 2, and the T port of the main reversing valve 3 is connected to the oil tank 5; the A port and the B port of the main reversing valve 3 are respectively connected to The rodless chamber of the boom hydraulic cylinder 4 is connected to the rod chamber; the cylinder barrel of the boom hydraulic cylinder 4 is hinged on the turntable 200, and the piston rod end of the boom hydraulic cylinder 4 is hinged at ...

Embodiment 2

[0068] Such as Figure 5 to Figure 7 As shown, an excavator arm energy-saving system includes an oil source 1, a first one-way valve 2, a main reversing valve 3, a boom hydraulic cylinder 4, a joystick of an excavator, a hydraulic motor 6, and an accumulator 10 , gearbox 8, first reversing valve 11, clutch 9, flywheel 7, second one-way valve 13, third one-way valve 14, fourth one-way valve 16, speed detection device and controller;

[0069] The oil source 1 is connected to the P port of the main reversing valve 3 through the first check valve 2, and the T port of the main reversing valve 3 is connected to the oil tank 5; the A port and the B port of the main reversing valve 3 are respectively connected to the boom hydraulic pressure The rodless chamber of the cylinder 4 is connected to the rod chamber; the cylinder barrel of the boom hydraulic cylinder 4 is hinged on the turntable 200, and the piston rod end of the boom hydraulic cylinder 4 is hinged at the middle of the boom ...

no. 1 example

[0102] 1. Energy recovery process

[0103] Assume that the boom hydraulic cylinder 4 has been stretched out at this time, and the boom 100 is at a higher position. When the boom 100 needs to be lowered, the operator sends a discharge signal under the boom to the controller through the corresponding button on the joystick, and the controller (not shown) controls the solenoid valve of the main reversing valve 3 after receiving the discharge signal under the boom. Iron Y1a, the electromagnet of the first reversing valve 11 and the clutch 9 are energized, and send a control signal X to the linear electric push rod 806 to control its extension to a set length, so that the gearbox 8 is switched to the working gear state A, and the working Gearbox 8 is the state of forward rotation during gear state A. At the same time, the controller sends a control signal A to the hydraulic motor 6 to adjust its displacement. The oil source 1 enters the rod cavity of the boom hydraulic cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com