An energy saving system for excavator arm

A technology of energy-saving system and motorized arm, which is applied to the components of fluid pressure actuation system, mechanically driven excavators/dredgers, earth-moving machines/shovels, etc., which can solve the problem of high overall cost, high cost and low cost of energy-saving systems. Practicality and other issues to achieve the effect of improving energy utilization efficiency, avoiding energy waste, and reducing power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

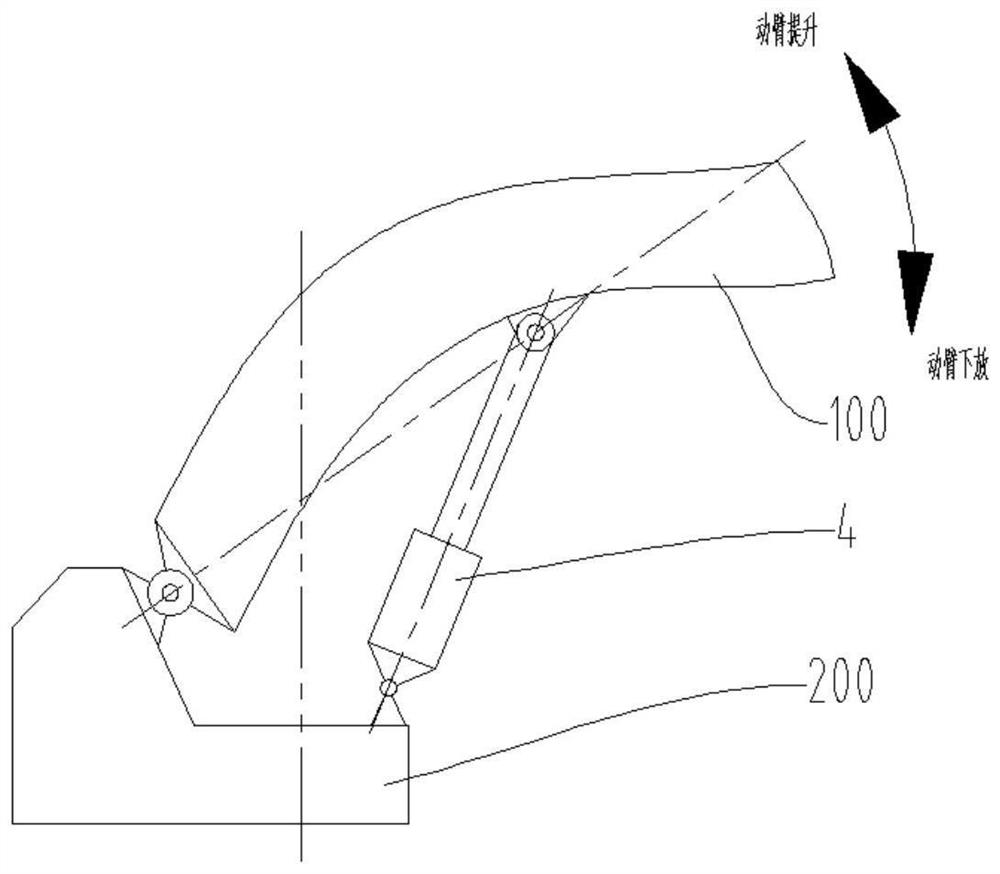

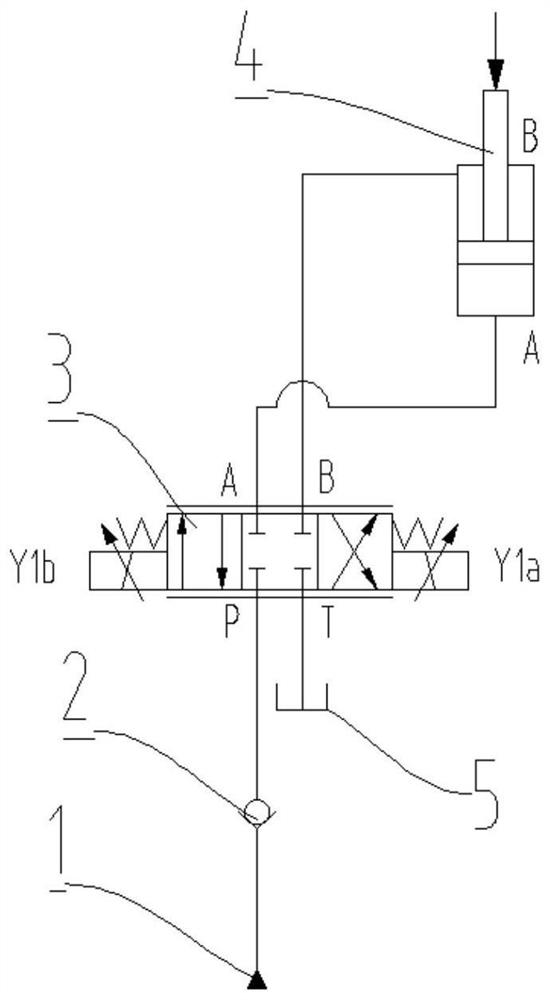

[0052] like Figure 4 , Image 6 and Figure 7 As shown, an energy saving system for an excavator arm includes an oil source 1, a first one-way valve 2, a main reversing valve 3, a boom hydraulic cylinder 4, a control handle of the excavator, a fifth one-way valve 17, a hydraulic Motor 6, accumulator 10, gearbox 8, first reversing valve 11, clutch 9, flywheel 7, second one-way valve 13, third one-way valve 14, fourth one-way valve 16, rotational speed detection device and The controller; the oil source 1 is connected to the P port of the main reversing valve 3 through the first check valve 2, and the T port of the main reversing valve 3 is connected to the oil tank 5; the A port and the B port of the main reversing valve 3 are respectively connected with The rodless cavity and the rod cavity of the boom hydraulic cylinder 4 are connected; the cylinder barrel of the boom hydraulic cylinder 4 is hinged on the turntable 200, and the piston rod end of the boom hydraulic cylinder...

Embodiment 2

[0068] like Figure 5 to Figure 7 As shown, an energy saving system for an excavator arm includes an oil source 1, a first one-way valve 2, a main reversing valve 3, a boom hydraulic cylinder 4, a control handle of the excavator, a hydraulic motor 6, and an accumulator 10. , gearbox 8, first reversing valve 11, clutch 9, flywheel 7, second one-way valve 13, third one-way valve 14, fourth one-way valve 16, rotational speed detection device and controller;

[0069] The oil source 1 is connected to the P port of the main reversing valve 3 through the first check valve 2, and the T port of the main reversing valve 3 is connected to the oil tank 5; the A port and the B port of the main reversing valve 3 are respectively connected with the boom hydraulic pressure. The rodless cavity and the rod cavity of the cylinder 4 are connected; the cylinder barrel of the boom hydraulic cylinder 4 is hinged on the turntable 200, and the piston rod end of the boom hydraulic cylinder 4 is hinged ...

no. 1 example

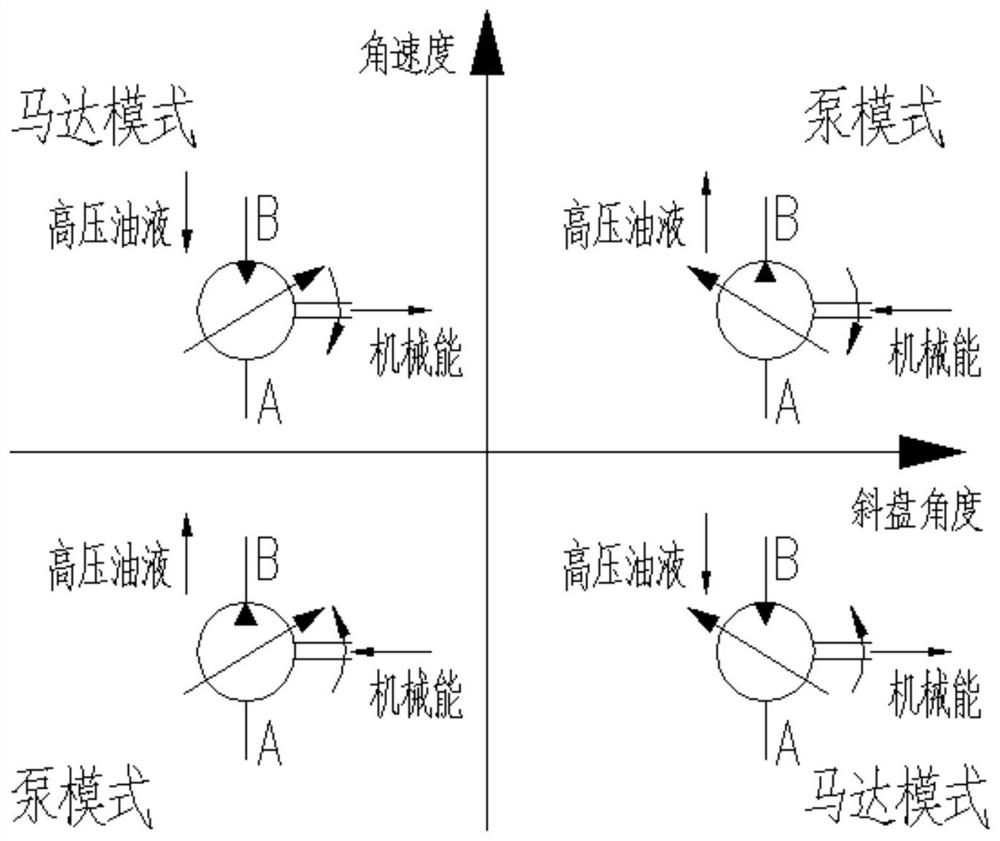

[0102] The energy recovery process

[0103] It is assumed that the boom hydraulic cylinder 4 has been extended at this time, and the boom 100 is in a higher position. When the boom 100 needs to be lowered, the operator sends a boom lower discharge signal to the controller through the corresponding button on the joystick, and the controller (not shown) controls the electromagnetic solenoid of the main reversing valve 3 after receiving the boom lower discharge signal. The iron Y1a, the electromagnet of the first reversing valve 11 and the clutch 9 are energized, and a control signal X is sent to the linear electric push rod 806 to control the extension of the set length, so that the gearbox 8 is switched to the working gear state A, and works In the gear state A, the transmission 8 is in a forward rotation state. At the same time, the controller sends a control signal A to the hydraulic motor 6 to adjust its displacement. The oil source 1 enters the rod cavity of the boom hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com