A kind of device and method for preparing benzene and xylene from toluene and heavy aromatics

A technology for heavy aromatics and xylene, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of hydrogen waste, PSA pressure swing adsorbent deactivation, etc., to reduce the amount of replenishment, reduce the impact, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

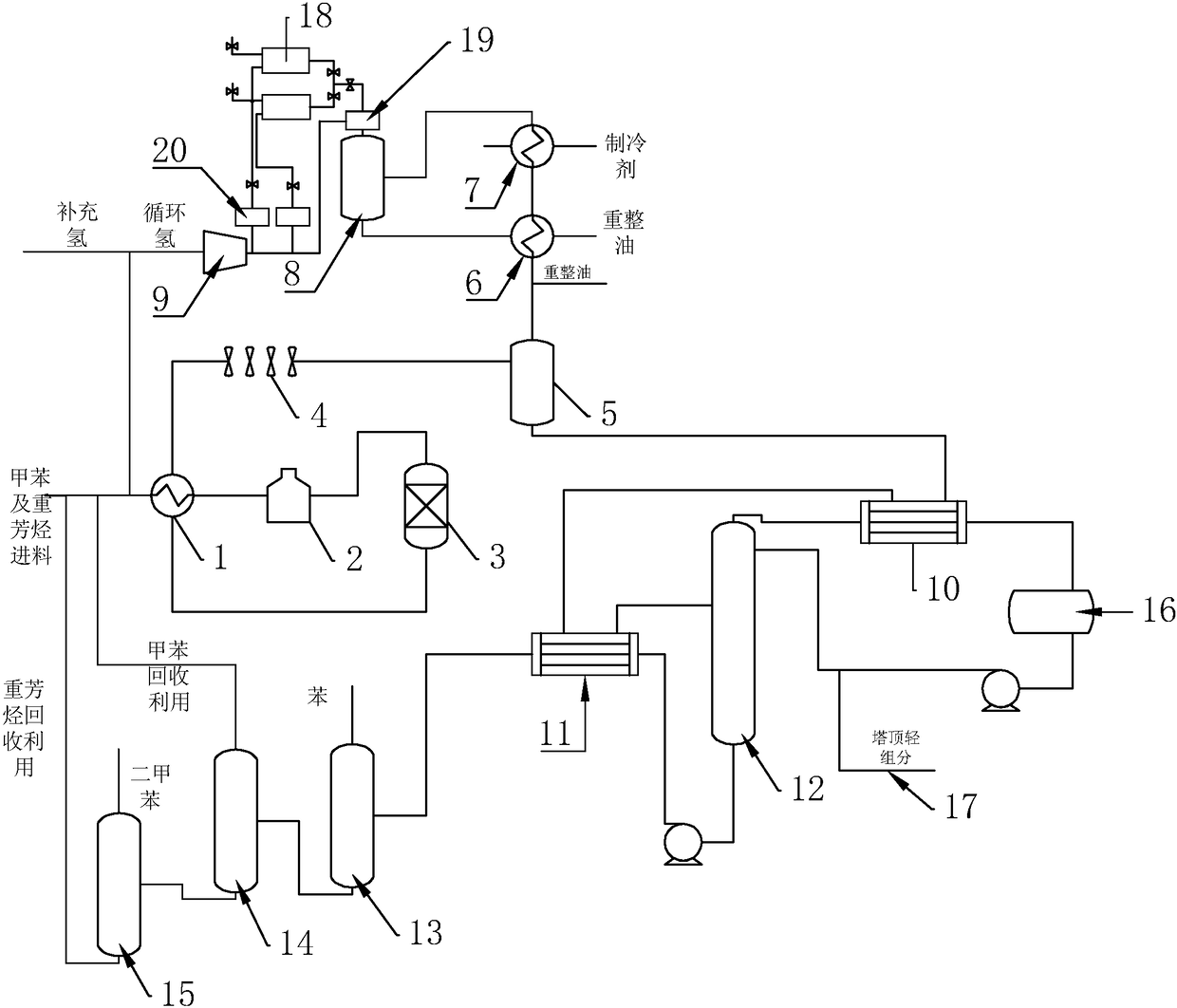

[0025] A method for preparing benzene and xylenes from toluene and heavy aromatics, comprising the following steps:

[0026] a. After mixing toluene, heavy aromatics and hydrogen, heat it through the feed heat exchanger 1 to 350°C with a pressure of 3.2MPa, then enter the feed heating furnace 2 for heating, and raise the temperature to 390°C with a pressure of 3.1MPa;

[0027] b. Enter reactor 3 for reaction, the reaction pressure is 1MPa, the reaction temperature is 350°C; the molar ratio of hydrogen to oil molecules is 3.0; the reaction space velocity is 3.0h -1 ;

[0028] c. After the reaction product comes out of the reactor 3, it is cooled to 110°C through the feed heat exchanger 1, and the pressure reaches 2.6MPa, and then cooled to 40°C through the air cooler 4, and the pressure reaches 2.0MPa, and then enters the gas-liquid separation tank 5 ;

[0029] d. The gas-liquid separation tank 5 divides the reaction product into two streams of gas phase and liquid phase. The...

Embodiment 3

[0035] A method for preparing benzene and xylenes from toluene and heavy aromatics, comprising the following steps:

[0036] a. After mixing toluene, heavy aromatics and hydrogen, heat it through the feed heat exchanger 1 to 400°C, the pressure is 3.2MPa, and then enter the feed heating furnace 2 to heat, and the temperature is raised to 400°C, the pressure is 3.1MPa;

[0037] b. Enter reactor 3 for reaction, the reaction pressure is 3MPa, the reaction temperature is 450°C; the molar ratio of hydrogen to oil molecules is 4.5; the reaction space velocity is 3.5h -1 ;

[0038] c. After the reaction product comes out of the reactor 3, it is cooled to 130°C through the feed heat exchanger 1, and the pressure reaches 2.8MPa, and then cooled to 60°C through the air cooler 4, and the pressure reaches 2.6MPa, and then enters the gas-liquid separation tank 5 ;

[0039] d. The gas-liquid separation tank 5 divides the reaction product into two streams of gas phase and liquid phase. The...

Embodiment 4

[0045] A method for preparing benzene and xylenes from toluene and heavy aromatics, comprising the following steps:

[0046] a. After mixing toluene, heavy aromatics and hydrogen, heat it through the feed heat exchanger 1 to 380°C with a pressure of 3.2MPa, and then enter the feed heating furnace 2 to heat up to 410°C with a pressure of 3.1MPa;

[0047] b. Enter reactor 3 for reaction, the reaction pressure is 2MPa, the reaction temperature is 380°C; the molar ratio of hydrogen to oil molecules is 3.5; the reaction space velocity is 3.2h -1 ;

[0048] c. After the reaction product comes out of the reactor 3, it is cooled to 120°C through the feed heat exchanger 1, and the pressure reaches 2.7MPa, and then cooled to 50°C through the air cooler 4, and the pressure reaches 2.5MPa, and then enters the gas-liquid separation tank 5 ;

[0049] d. The gas-liquid separation tank 5 divides the reaction product into two streams of gas phase and liquid phase. The gas phase stream is mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com