Excavator rotary motor and excavator rotary hydraulic system

A technology of rotary motors and hydraulic systems, which is applied to earth movers/shovels, construction, etc., and can solve problems such as complex connections, multiple pipelines, and hydraulic oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

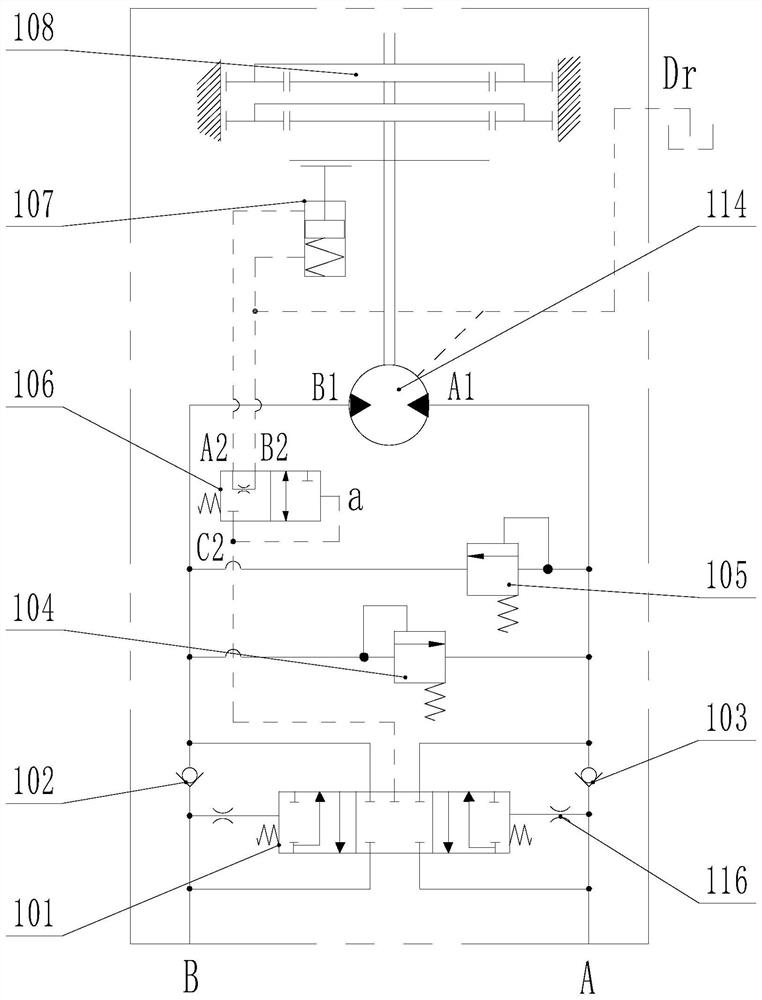

[0033] An excavator slewing motor, including a slewing motor 1, the slewing motor 1 includes a brake valve 106, a brake cylinder 107, a motor 114, a slewing device and a braking device, the motor 114 is connected to the slewing device, and the brake The actuator is respectively connected to the C2 port of the brake valve 106 and the signal a port, the A2 port of the brake valve 106 is connected to the brake cylinder 107, and the B2 port is connected to the Dr port. The spring chamber of the brake oil cylinder 107 is connected to the Dr port, and the Dr port is connected back to the hydraulic oil tank 6 . The motor 114 is connected to the reducer 108, and the reducer 108 decelerates the motor 114 to output.

[0034] The rotary motor 1 also includes a relief valve A104 and a relief valve B105, the oil ports on both sides of the motor 114 are respectively connected with the relief valve A104 and the relief valve B105, and the relief valve A104 and the relief valve B105 are connec...

Embodiment 2

[0036] Such as figure 1 As shown, an excavator slewing motor, the brake device includes a balance valve A101, the balance valve A101 is respectively connected with the C2 port of the brake valve 106, the signal a port, the motor 114, the external oil source A port and the external oil source Source B port connection.

[0037] The balance valve A101 has a three-position five-way structure. There are springs on both sides of the valve core for the return of the valve core. There are throttle holes 116 on both sides of the valve core of the balance valve A101. Through the throttle holes 116, the valve core can be made smooth and stable. Move with less shock.

[0038] The slewing device includes a one-way valve A102 and a one-way valve B103, and the signal oil ports on both sides of the balance valve A101 are respectively connected with the oil inlet of the one-way valve A102 and the oil inlet of the one-way valve B103, and the one-way valve A102 The oil outlet is connected to ...

Embodiment 3

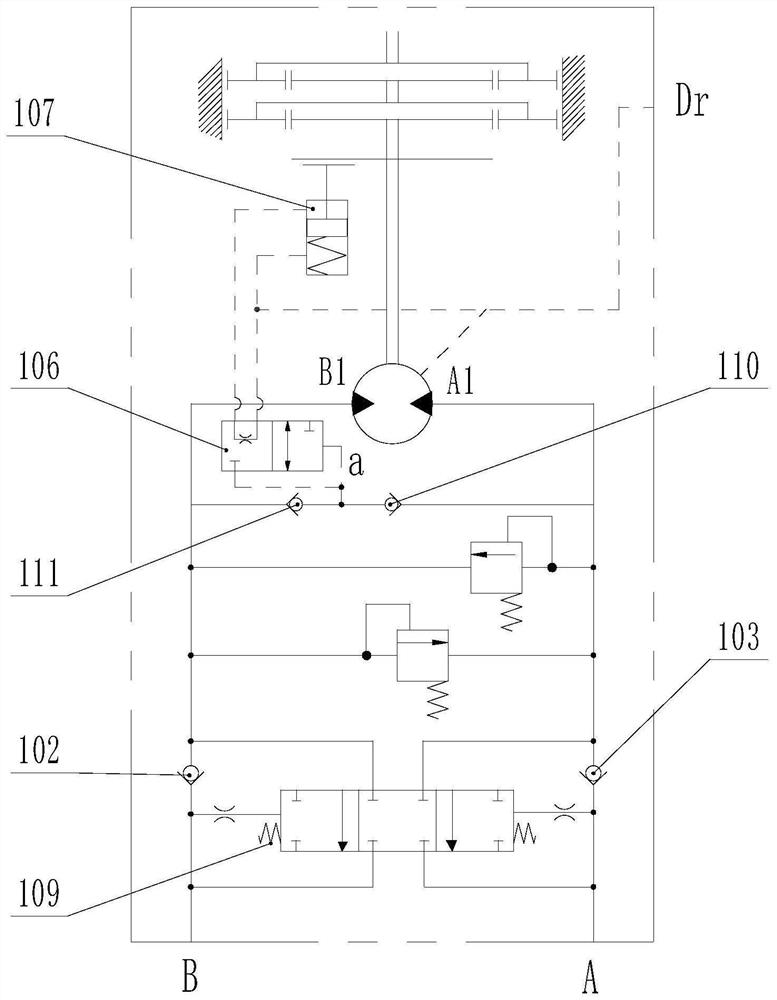

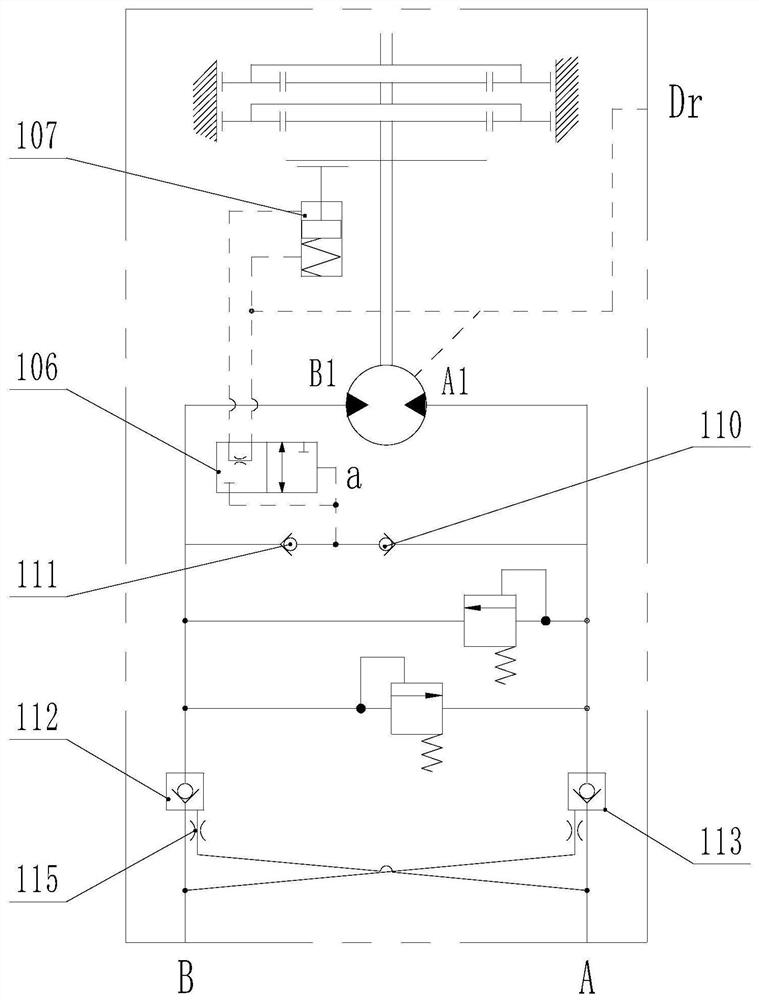

[0040] Such as figure 2 As shown, an excavator slewing motor, the brake device includes a check valve C110 and a check valve D111, the oil outlet of the check valve C110 and the oil outlet of the check valve D111 are respectively connected to the brake valve 106 The C2 port is connected to the signal a port. The one-way valve C110 and the one-way valve D111 take a pressure signal from the main oil circuit to act on the brake valve 106 .

[0041] The rotary device includes a one-way valve A102, a one-way valve B103 and a balance valve B109. The oil outlet of the one-way valve A102 is respectively connected with the oil inlet of the one-way valve D111 and the B1 side of the motor 114. The one-way valve The oil outlet of B103 is respectively connected with the oil inlet of the one-way valve C110 and the A1 side of the motor 114, and the balance valve B109 is connected with the B1 side, the A1 side, the external oil source A port and the external oil source B port of the motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com