Warehouse AGV with automatic transverse avoidance walking device after fault

A walking device and post-failure technology, applied in the direction of transmission, control device, motor vehicle, etc., to achieve the effect of smooth transmission of power, avoiding motion interference, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, obtaining other drawings based on these drawings belongs to the protection scope of the present invention without any creative effort.

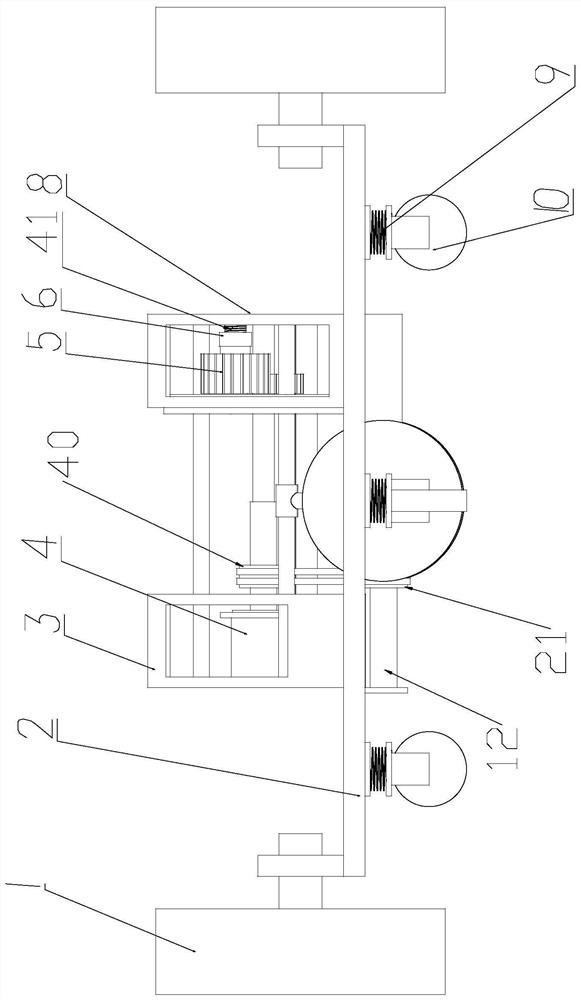

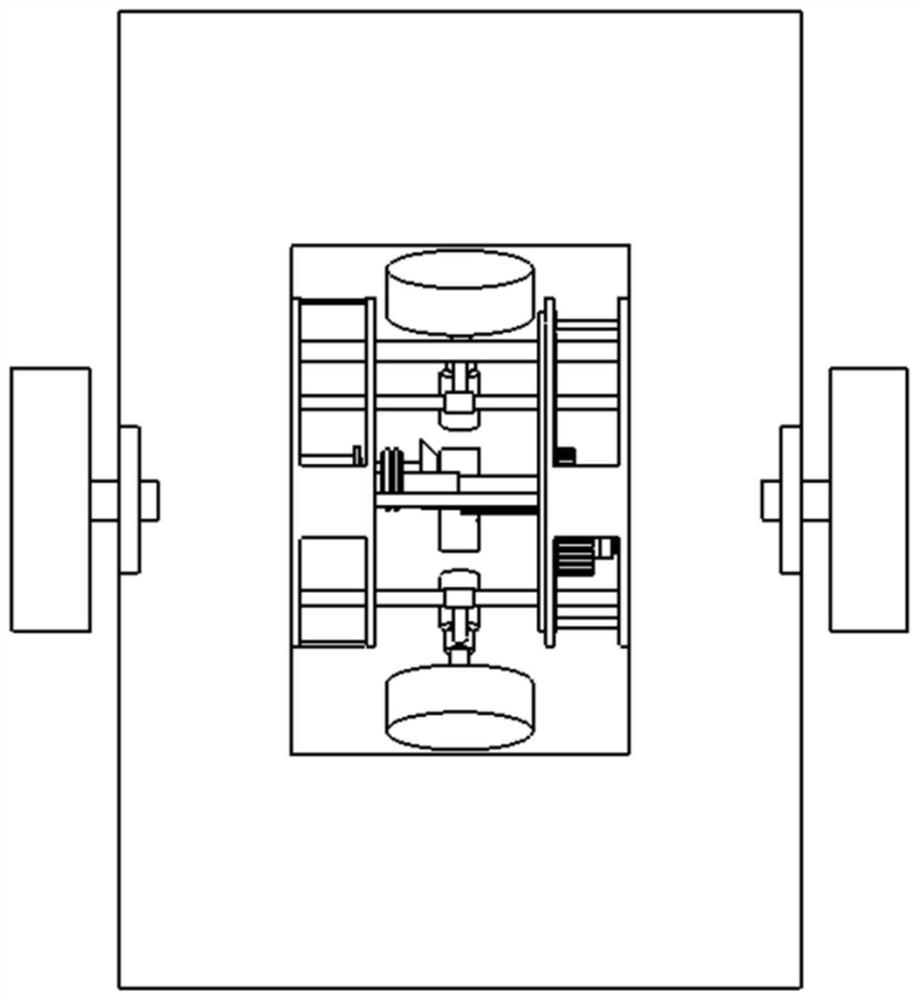

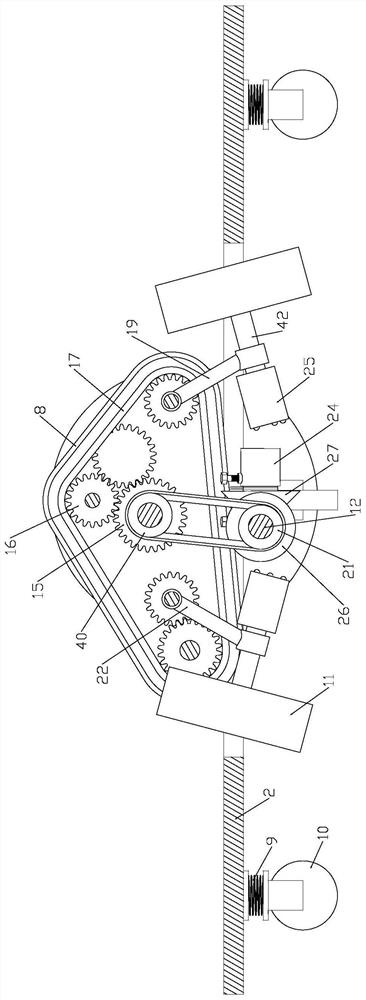

[0038] see as Figure 1 to Figure 7 As shown, the technical means adopted in the specific embodiment of the present invention are as follows: a storage AGV with an automatic lateral avoidance walking device after a failure, including an AGV chassis assembly and a lateral running device.

[0039] The AGV chassis assembly 2 includes two left and right uniaxial hub motors 1, four spring connectors 9 and four universal wheels 10; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com