Obliquely-arranged ultrasonic atomization sheet structure, atomizer and electronic cigarette

A technology of ultrasonic atomizing sheets and atomizers, which is applied in the field of electronic cigarettes, can solve the problems of slow atomization of e-liquid, inability to atomize smoke, and inconvenient use, so as to improve the working speed and user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

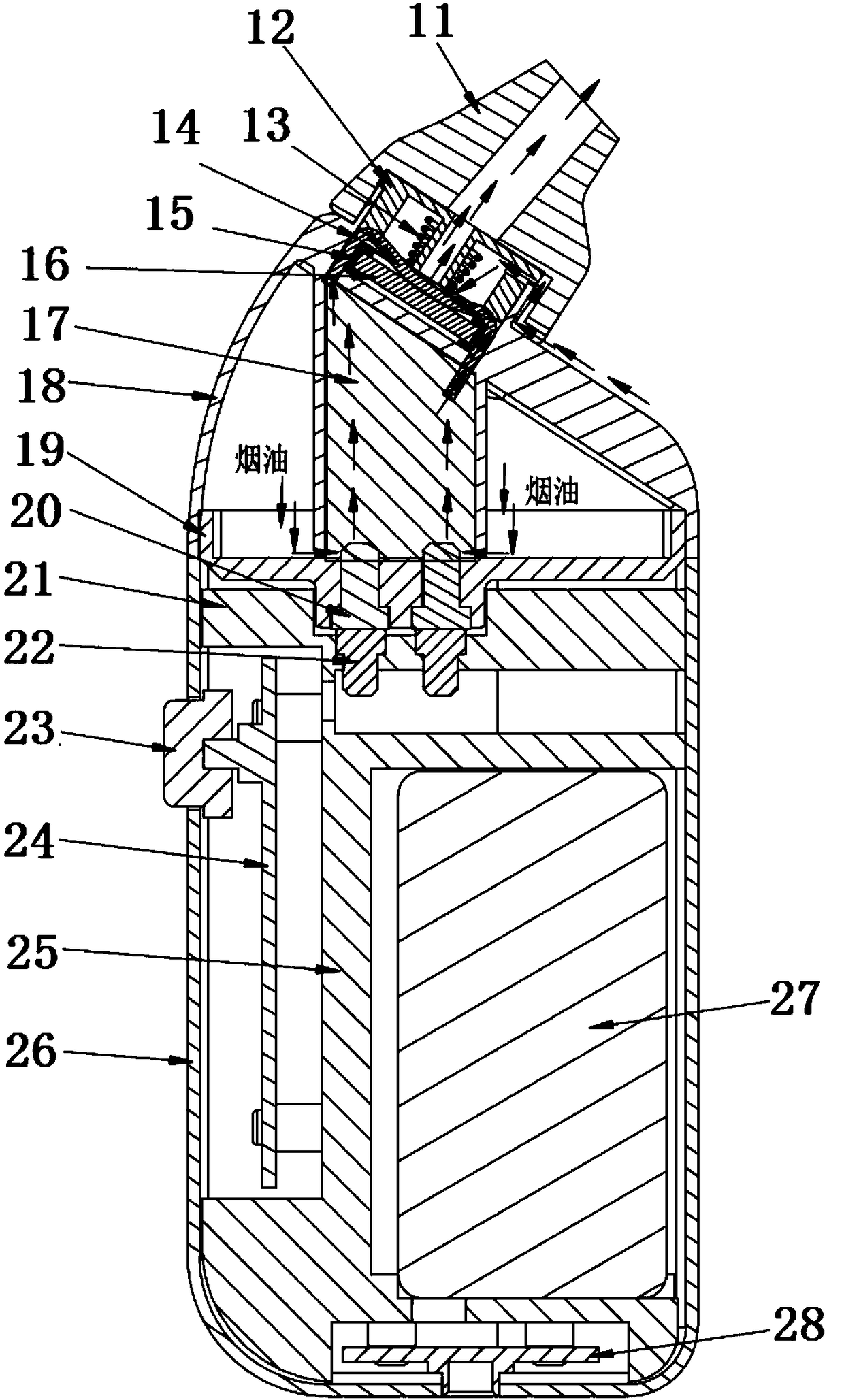

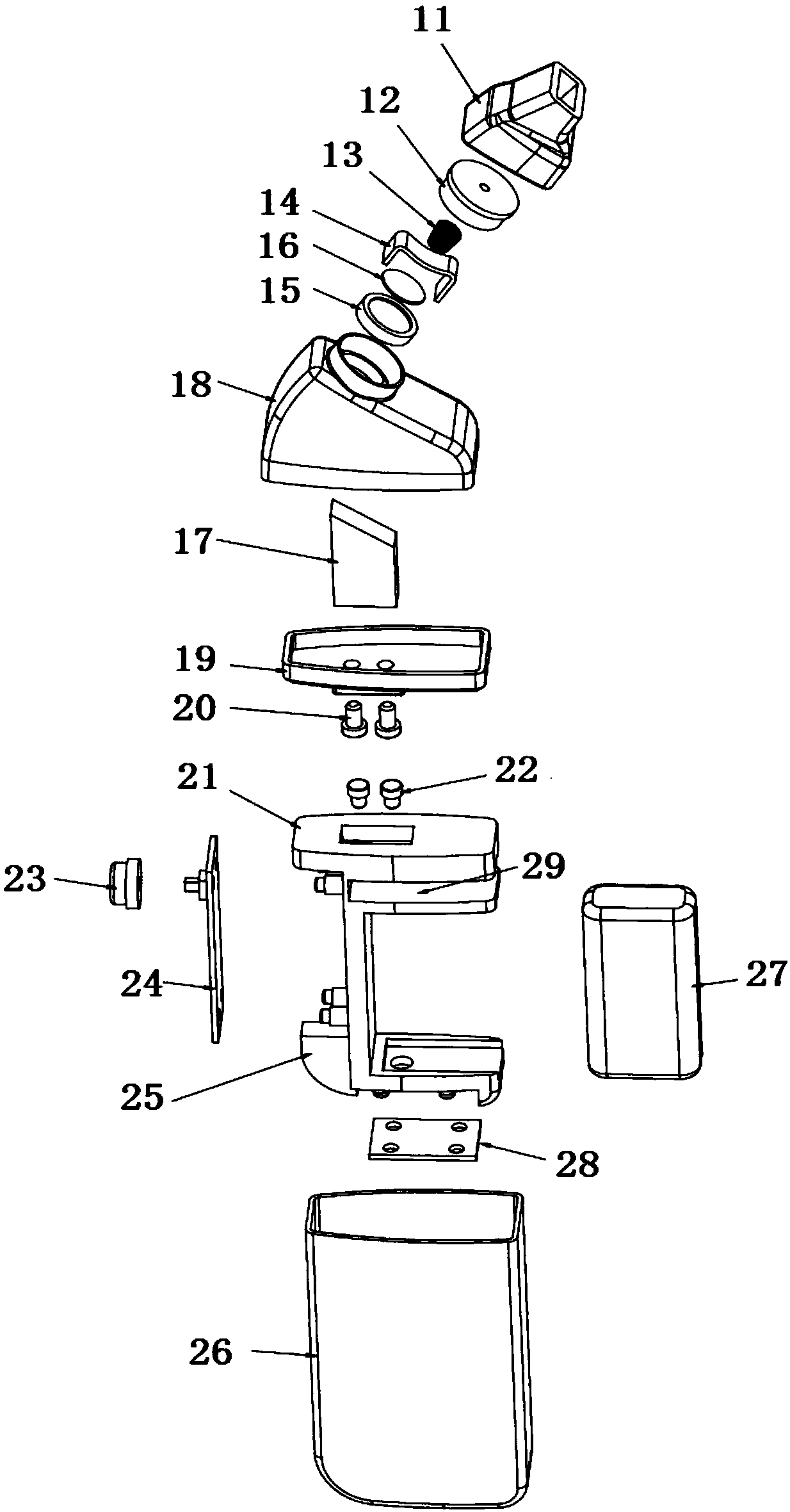

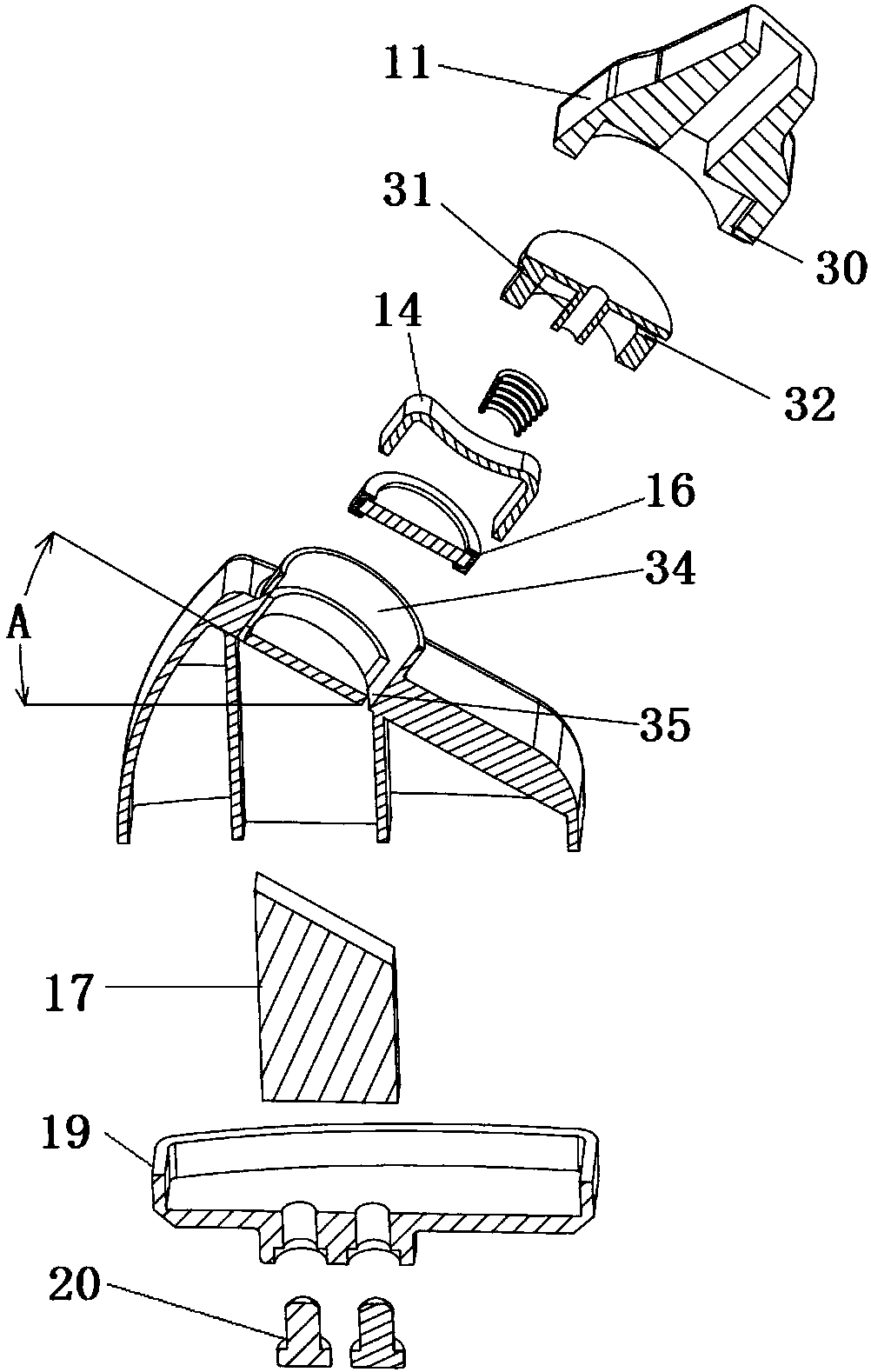

[0048] An oblique ultrasonic atomizing sheet structure, such as image 3 As shown, it includes atomized cotton 14, piezoelectric ceramics 16 and oil-conducting cotton 17. The lower end of the oil-conducting cotton 17 is immersed in the oil cavity, and the two ends of the atomized cotton 14 are in contact with the oil-conducting cotton 17, so that the smoke oil is transmitted to the atomized cotton 14 through the oil-conducting cotton 17, and then the piezoelectric ceramic 16 Only in this way can the e-liquid in the atomizing cotton 14 be atomized to produce smoke, and the flow rate of the e-liquid can be well controlled to affect the atomization rate.

[0049] The atomized cotton 14 of the present invention is compressed on the atomized surface of the piezoelectric ceramic 16 by the compression spring 13, so that the atomized cotton 14 and the piezoelectric ceramic will not be generated due to the vibration of the piezoelectric ceramic 16 when the atomizer is in operation. 16...

Embodiment 2

[0064] An oblique ultrasonic atomizing sheet structure, such as Figure 7 As shown, atomized cotton 14 and piezoelectric ceramics 16 are included. The two ends of the atomized cotton 14 are directly immersed in the oil cavity, so that the smoke oil is transmitted to the piezoelectric ceramic 16 through the atomized cotton 14, and the smoke oil in the atomized cotton 14 is atomized to produce smoke, which has good smoke control. The oil flow rate affects the atomization rate.

[0065] The atomized cotton 14 of the present invention is pressed on the atomized surface of the piezoelectric ceramic 16 through the silica gel seat 13, so that the atomized cotton 14 and the piezoelectric ceramic will not be generated due to the vibration of the piezoelectric ceramic 16 when the atomizer 1 is in operation. 16 Poor contact.

[0066] The piezoelectric ceramic 16 in this embodiment is similar to the ultrasonic atomizing sheet in Embodiment 1, and is driven by a conductor to form an ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com