Active lubrication valve mechanism and engine

A valve train, active technology, applied in the direction of machine/engine, engine components, engine lubrication, etc., can solve the problems of thick base circle of bearing lubricating oil film, difficulty in bearing lubricating oil film, high working pressure, etc. The effect of improving running accuracy and reducing running noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

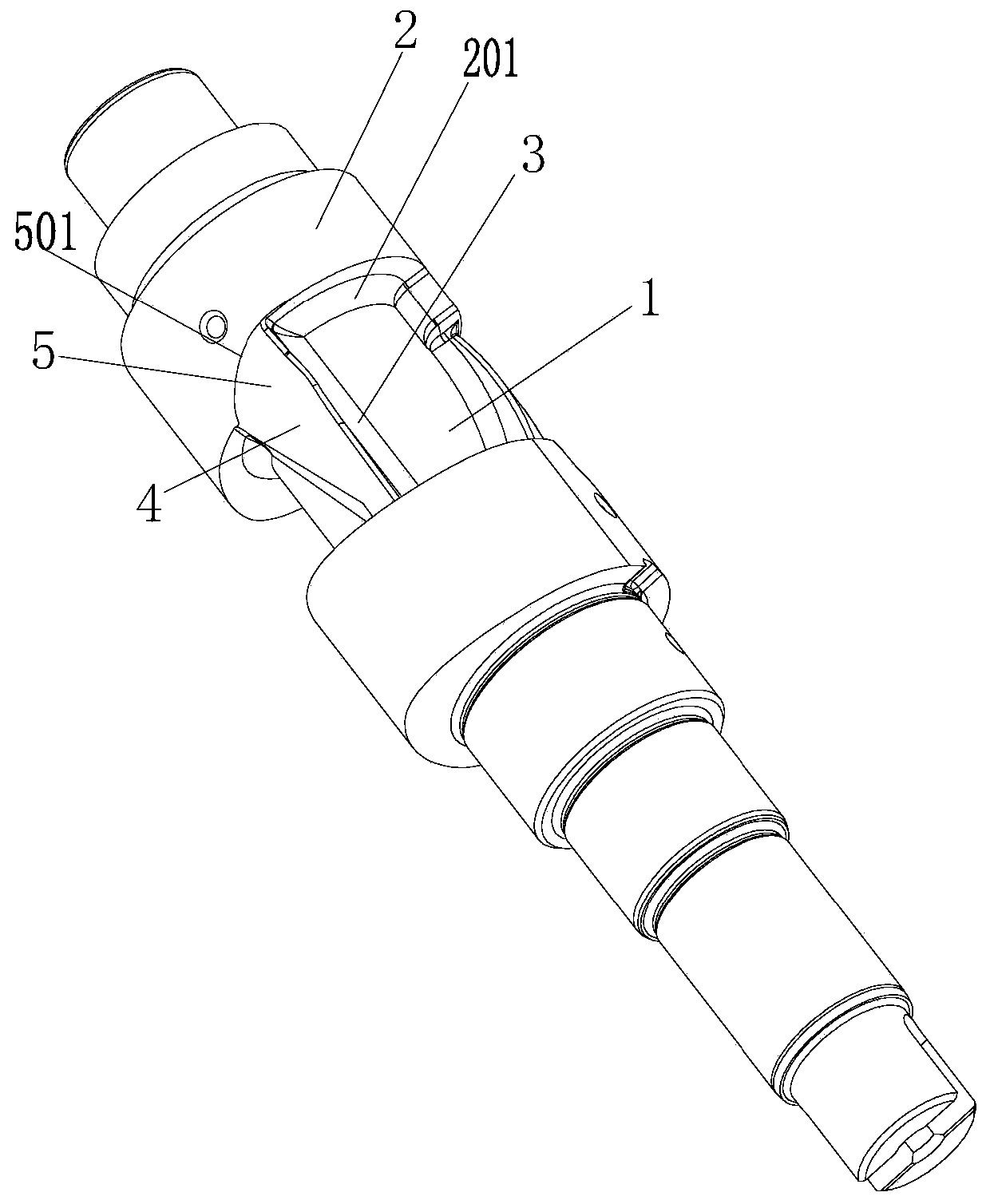

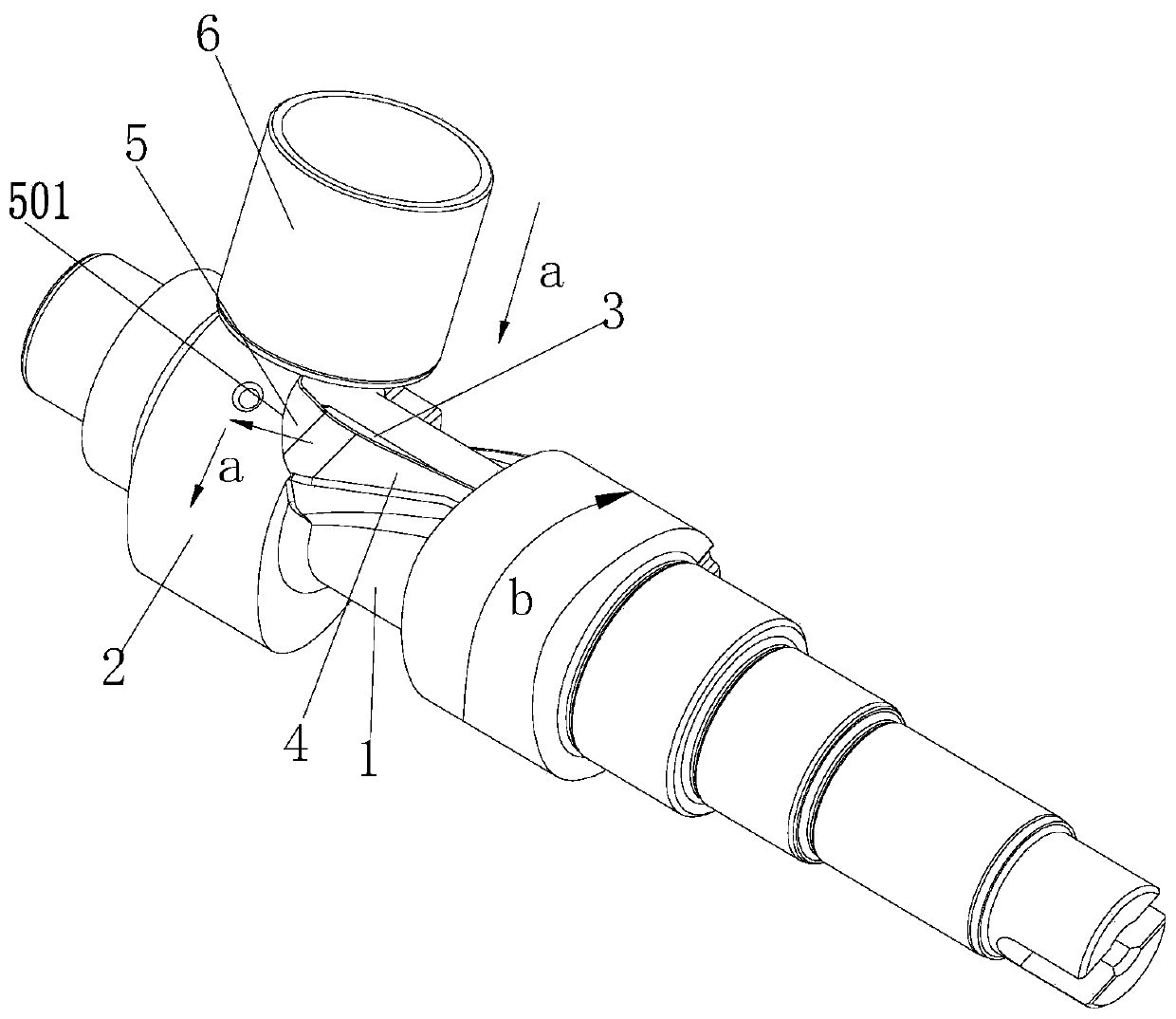

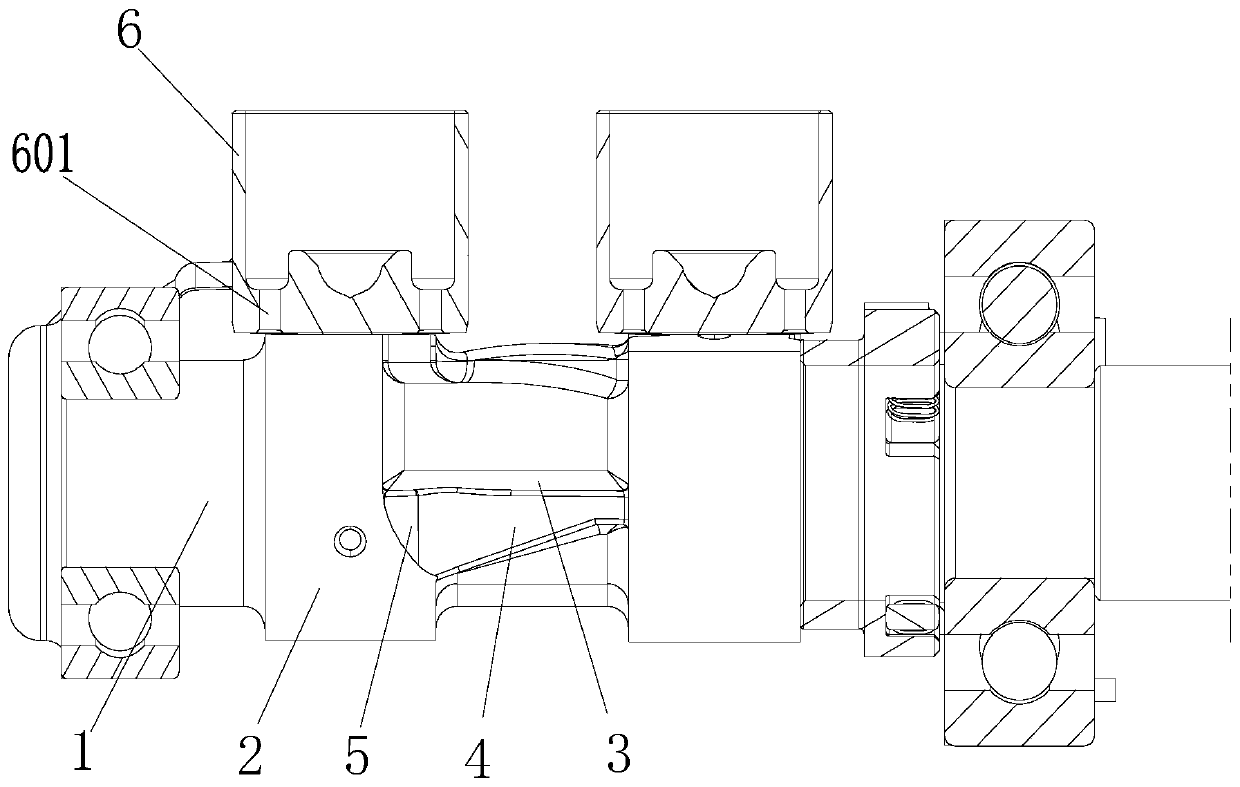

[0027] figure 1 It is a schematic diagram of the three-dimensional structure of the camshaft of the present invention, figure 2 It is a three-dimensional structure diagram of the gas distribution mechanism of the present invention, image 3 It is a sectional view of the gas distribution mechanism of the present invention, Figure 4 It is a top view of the valve train of the present invention, Figure 5 It is the general diagram of the engine of the present invention, as shown in the figure: the actively lubricated valve train of the present embodiment includes a camshaft and a tappet 6, and the camshaft includes a camshaft body 1 and at least one cam 2, and the tappet The column and the cam of the camshaft can be driven to contact and cooperate. The outer surface of the camshaft body 1 (referring to the shaft section other than the cam) is provided with an oil guide slope 3, and the oil guide slope 3 is rotated when the camshaft rotates. guide the lubricating oil on the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com