Compressor and refrigeration device

A technology for a compressor and a driving motor, applied in the field of compressors, can solve the problems of poor reliability of the upper bearing, poor reliability of the compressor, poor stiffness of the crankshaft, etc., so as to improve the operation stability and reliability, improve the reliability and use Longevity and wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

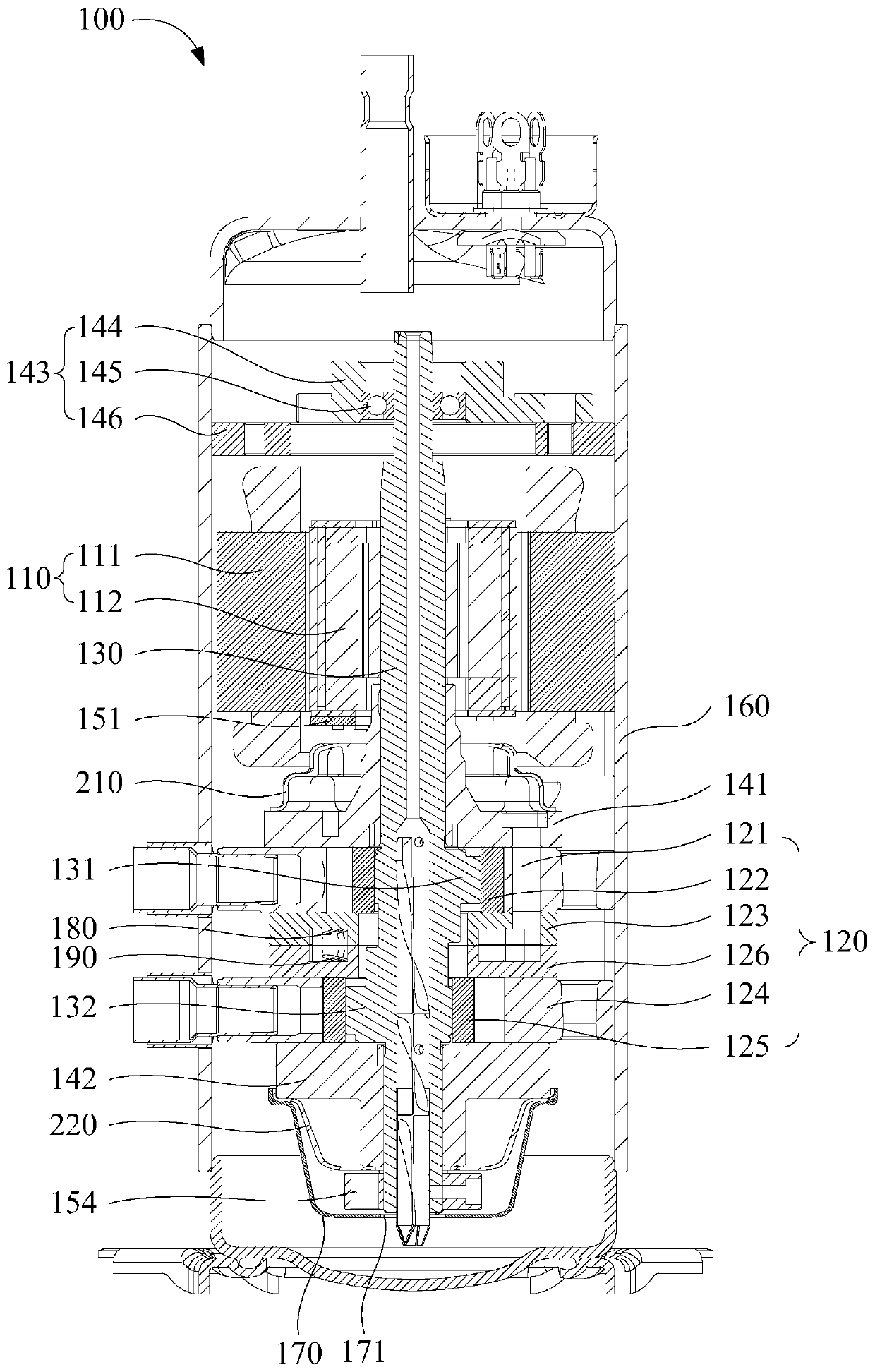

[0045] Such as figure 1 and figure 2 As shown, the first aspect embodiment of the present invention proposes a compressor 100 with a maximum speed greater than or equal to 150rps (revolution / second), including a housing 160, a drive motor 110, a compression assembly 120, a crankshaft 130, a bearing system and a balance system. Wherein, the bottom of housing 160 is configured as an oil pool; drive motor 110 includes stator 111 and rotor 112; compression assembly 120 includes a first cylinder 121, a first piston 122, a second cylinder 124, a second piston 125, and a first cylinder 121 and the partition plate of the second cylinder 124, the first piston 122 is arranged in the first cylinder 121, the second piston 125 is arranged in the second cylinder 124; the crankshaft 130 has a first eccentric part 131 and a second eccentric part 132, the second An eccentric part 131 and a second eccentric part 132 are relatively distributed around the rotation centerline of the crankshaft ...

Embodiment 2

[0050] Different from Embodiment 1, the rotation centerlines of the first eccentric portion 131 and the second eccentric portion 132 around the crankshaft 130 are 90° apart. That is, the projections of the first eccentric portion 131 and the second eccentric portion 132 on a cross section of the crankshaft 130 differ by 90° in central angle.

[0051] Of course, it is also possible to have a difference of 60° or 120° around the rotation centerline of the crankshaft 130 and so on.

Embodiment 3

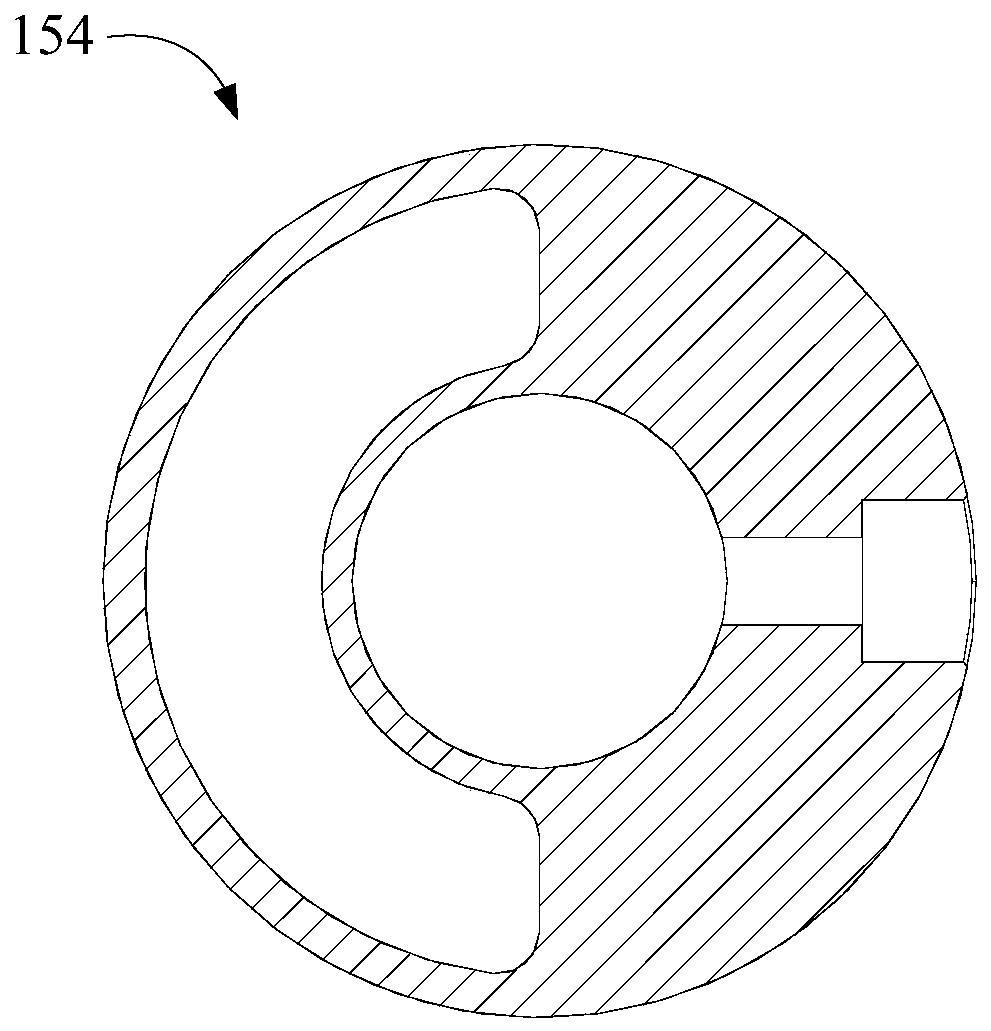

[0053] On the basis of the first or second embodiment above, it is further set that the center of mass of the rotor balance weight 151 and the first eccentric portion 131 are relatively distributed around the center line of rotation of the crankshaft 130; They are relatively distributed around the rotation centerline of the crankshaft 130 . So that no matter how the first eccentric part 131 and the second eccentric part 132 are distributed, the unbalanced force and moment brought by the eccentric movement of the first eccentric part 131 and the first piston 122 can be offset by the rotor balance weight 151, and The unbalanced force and moment caused by the eccentric movement of the second eccentric portion 132 and the second piston 125 is offset by the crankshaft balance weight 154 . Since the first eccentric part 131 and the second eccentric part 132 do not need to be independently balanced by the rotor balancing weight 151, the weight of the rotor balancing weight 151 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com