Novel combined bearing

A combined bearing, a new type of technology, used in bearing elements, shafts and bearings, ball and roller bearings, etc., can solve problems such as bearing damage and insufficient oil supply to bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

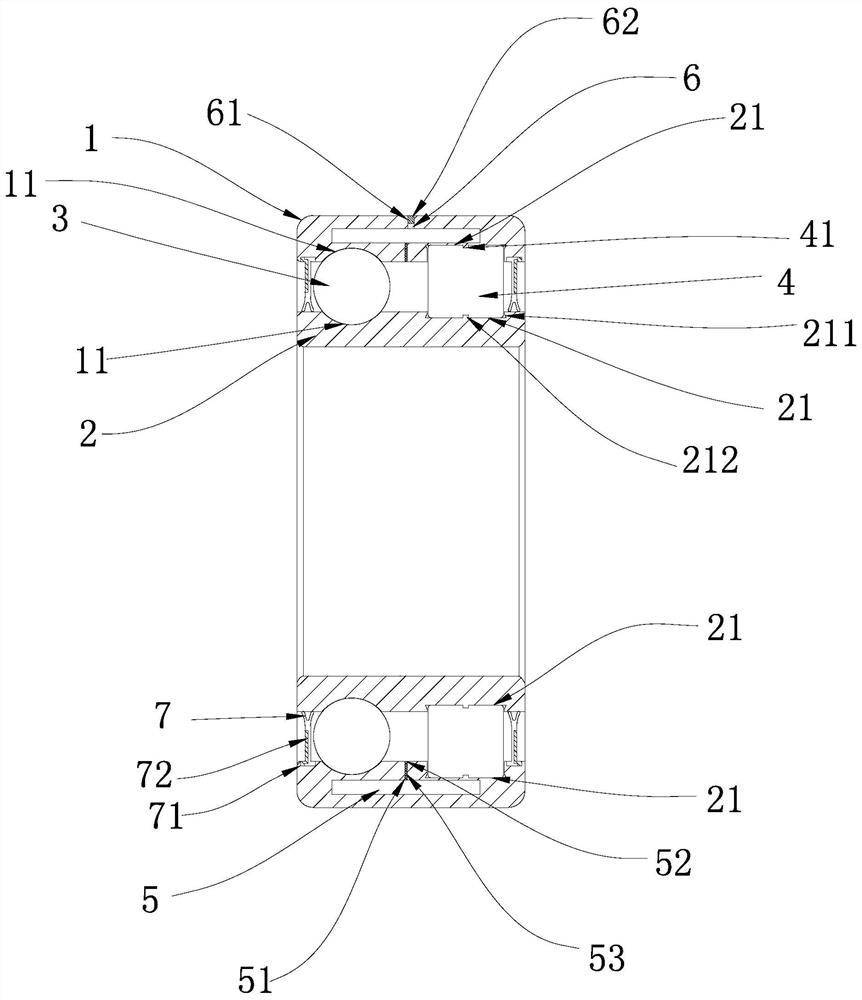

[0015] The present invention provides a new type of composite bearing, which includes an outer ring 1, an inner ring 2, a row of balls 3 and a row of cylindrical rollers 4, and the inner peripheral wall of the outer ring 1 and the outer peripheral wall of the inner ring 2 are circumferentially provided with a row of balls. 3 rolling first raceway 11, the inner peripheral wall of the outer ring 1 and the outer peripheral wall of the inner ring 2 are circumferentially provided with a second raceway 21 for a row of cylindrical rollers 4 to roll, the first raceway 11 is located On one side of the second raceway 21, abutment grooves 211 for preventing the cylindrical rollers 4 from bearing excessive overturning moments are provided on the inner walls of both sides of the two second raceways 21. Limiting rings 212 protrude from the surrounding walls to prevent the cylindrical rollers 4 from bearing excessive overturning moments, and each of the cylindrical rollers 4 is circumferentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com