Self-cooling horizontal type rolling rotor compressor

A rolling rotor, self-cooling technology, used in machines/engines, liquid fuel engines, rotary piston machines, etc., can solve the problems of rotor churning loss that cannot be ignored, insufficient oil supply, and low oil level at the oil suction pipe. The effect of improving reliability, increasing oil level, and increasing motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

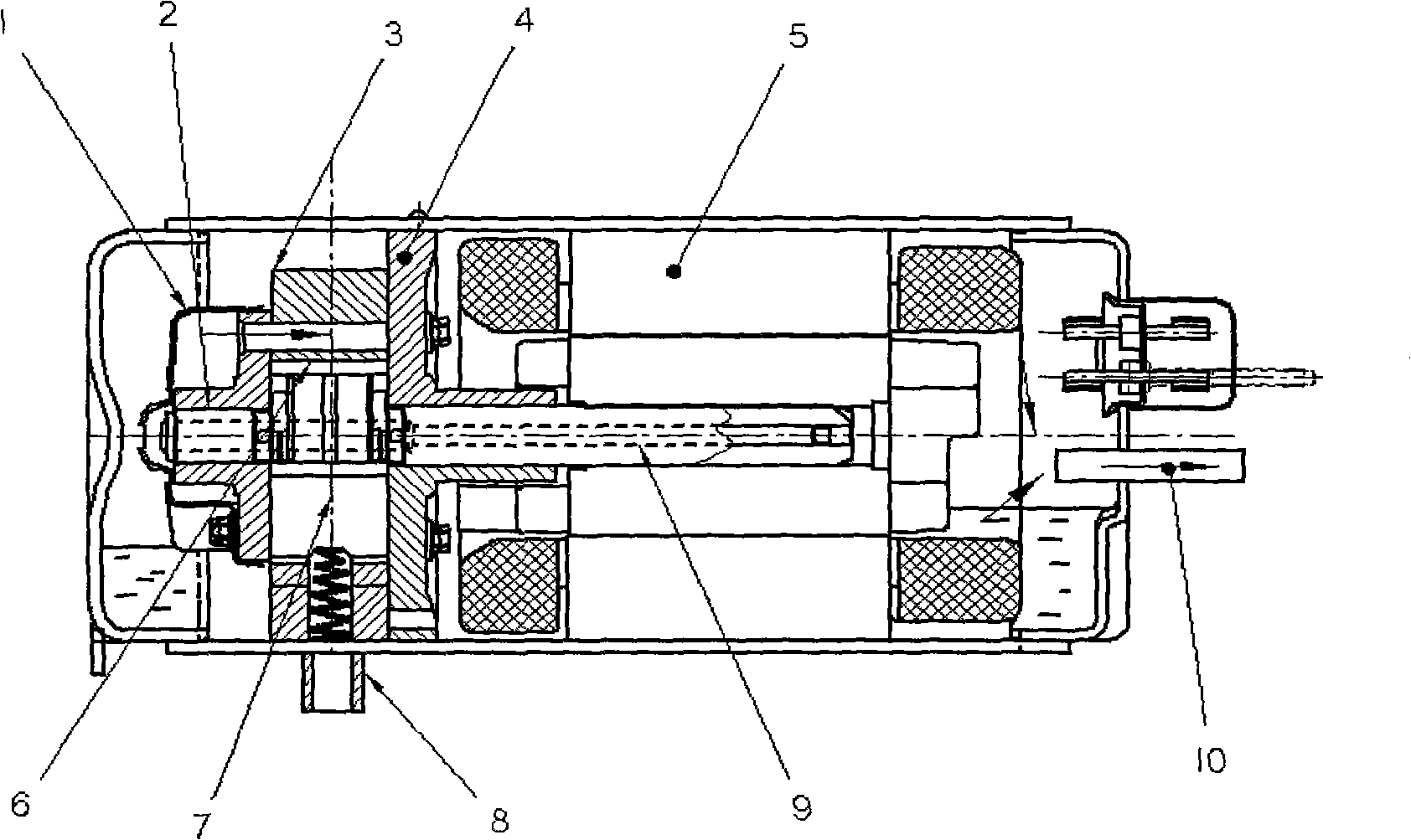

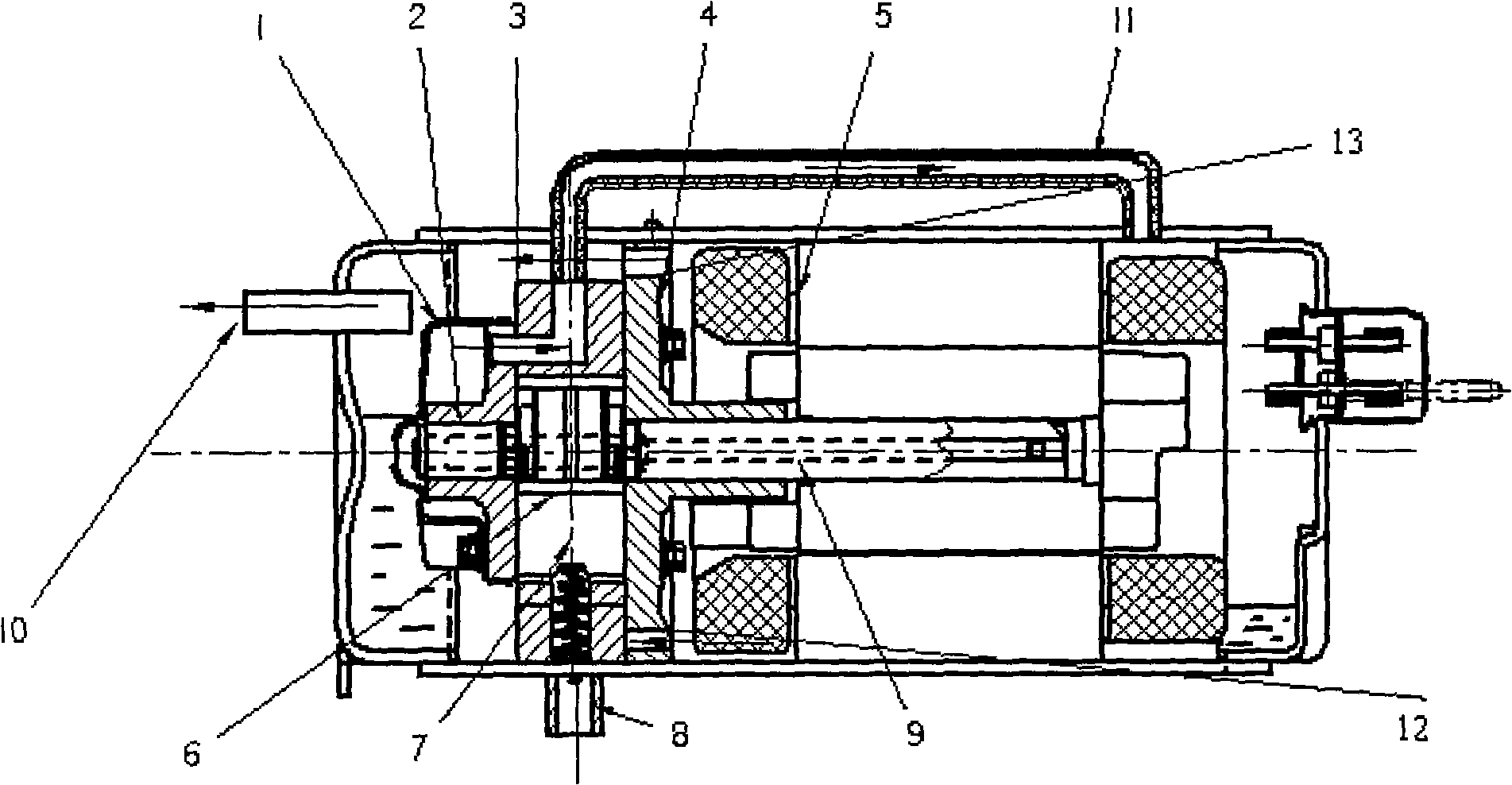

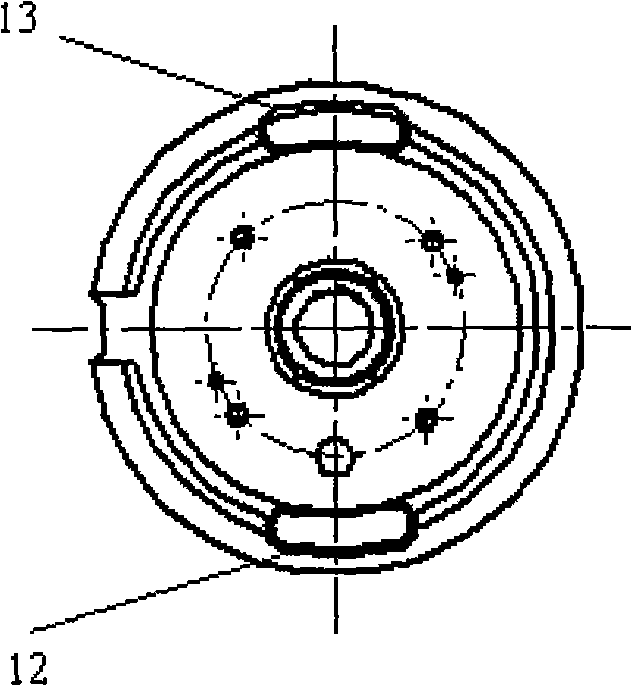

[0020] Such as Figure 2~3 As shown, a self-cooling horizontal rolling rotor compressor, the compressor structure is as follows: parts 2 (lower cylinder head), 3 (cylinder), 4 (upper cylinder head) are assembled together by bolts to form a static compression part Part 9 (crankshaft), 6 (piston) and 7 (vane) constitute the moving part, which is driven by 5 (motor) to rotate the crankshaft to complete the process of compressing the gas. 1 (lower muffler) is installed outside the lower exhaust to start To eliminate exhaust noise. 8 (intake pipe) and 10 (exhaust pipe) complete the gas input and output work, and the whole structure is sealed by the closed shell. 11 (air return pipe) acts as an exhaust guide, and is used to guide the exhaust to cool the motor and improve the height of the oil level on the side of the pump body.

[0021] With 4 (upper cylinder head) as the partition, the inside of the housing is divided into a compression chamber and a motor chamber. Exhaust gas e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com