Computer flat knitting machine yarn nozzle sliding seat

A computerized flat knitting machine and sliding seat technology, which is applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of short service life, dripping, movement obstruction, etc., to improve weaving quality, reduce wear, and reduce friction Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

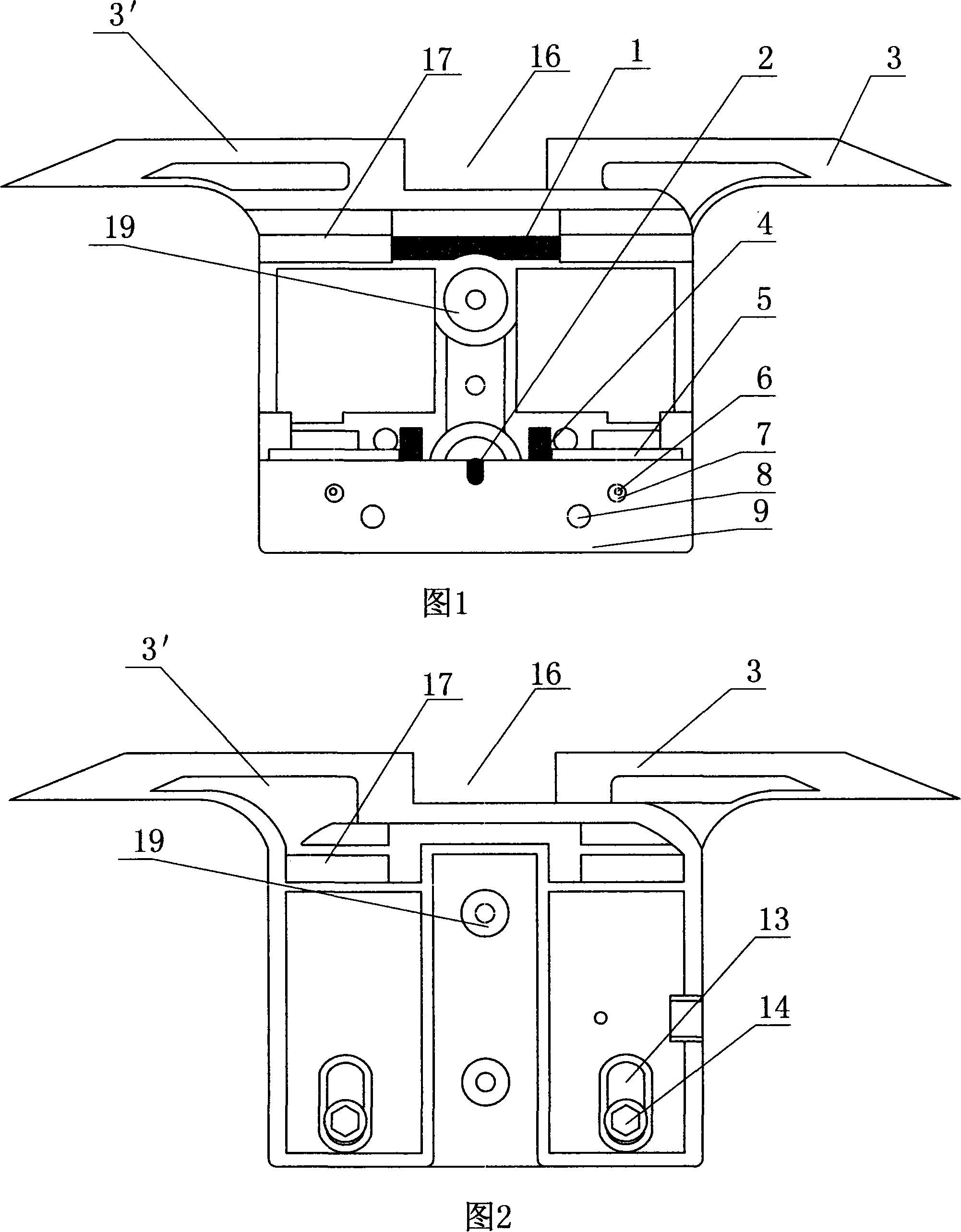

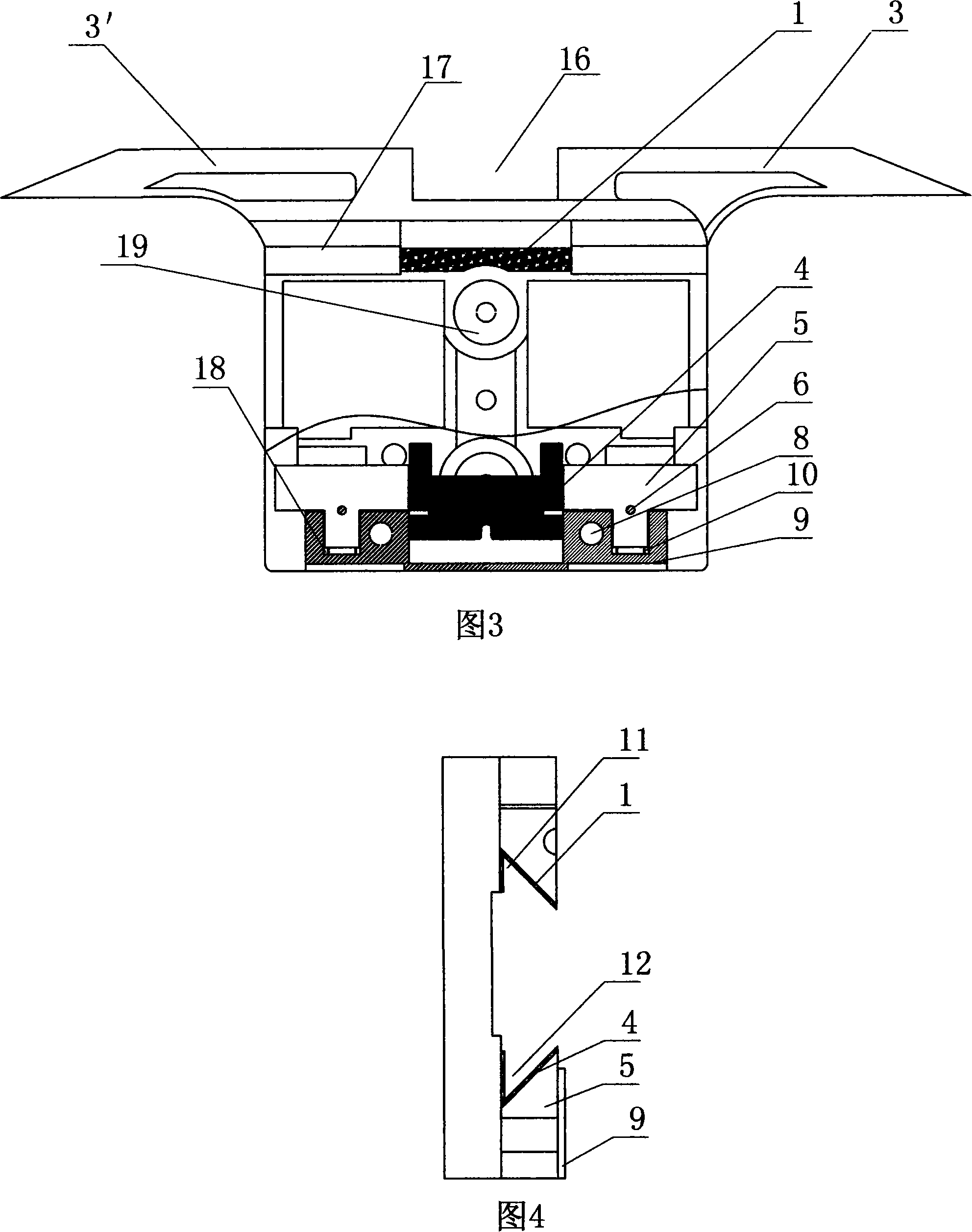

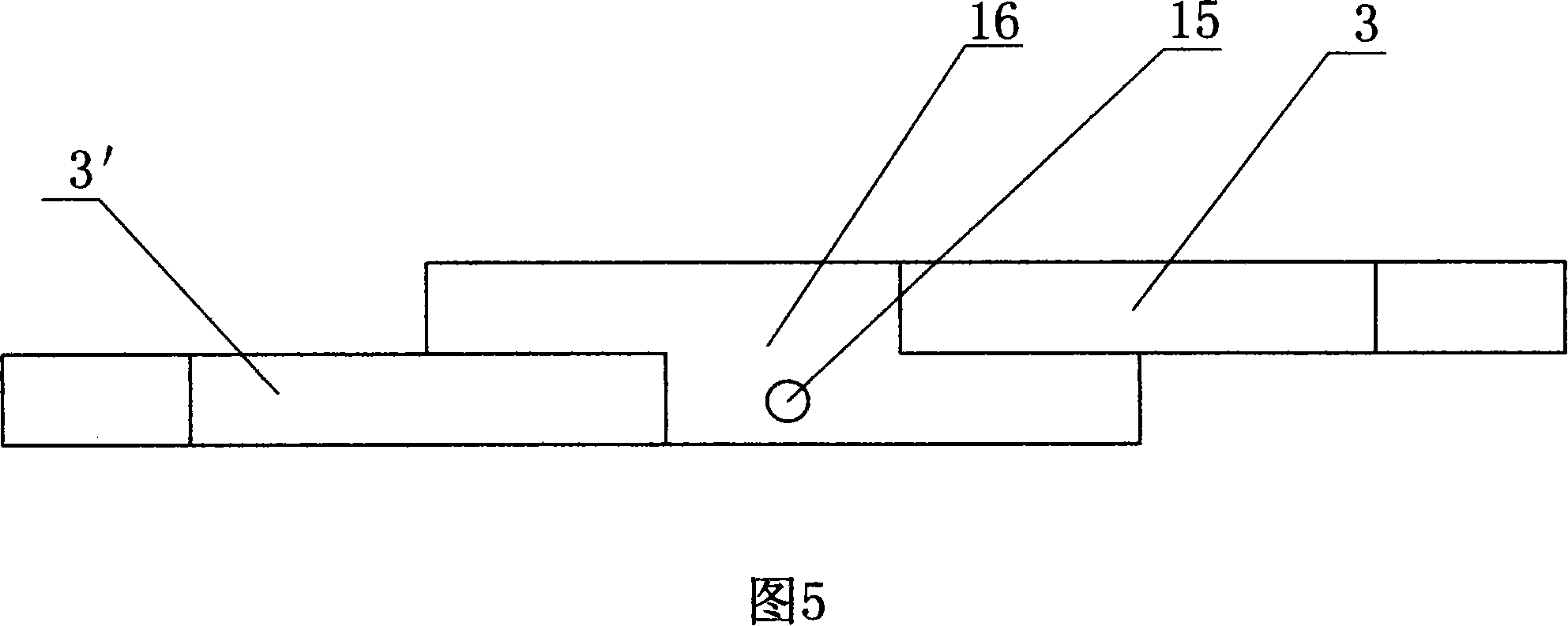

[0012] Referring to the accompanying drawings, the computerized flat knitting machine yarn feeder sliding seat has a main body 17 and a cover plate 9, the cover plate 9 is arranged on the lower part of the main body 17, and left and right slideways 3, 3' are arranged on the upper end of the main body 17, and the left and right sliding There is a certain distance between the roads 3 and 3', and a groove 16 is formed. A first angular groove 11 is arranged on the top of the body 17, and a groove 18 is arranged on the cover plate 9. The protruding part of the sliding block 5 and the spring 10 are placed together in the groove 18 after being connected. The upper end of the sliding block 5 is a wing-shaped plate with a slope on the upper side of the wing plate. The slope and the body 17 form a second angle groove 12, and the second angle groove 12 corresponds to the first corner groove 11, the so-called corresponding means that the direction of the corner is opposite, the first corne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com