Refrigerating machine oil, working fluid composition and refrigeration cycle device

A refrigerating machine oil and refrigerant technology, which is applied in lubricating compositions, refrigerators, petroleum industry, etc., can solve the problems of refrigerating machine oil, such as reduced lubrication, bad, poor oil return of refrigerating machine oil, etc., and achieve the effect of widening the selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

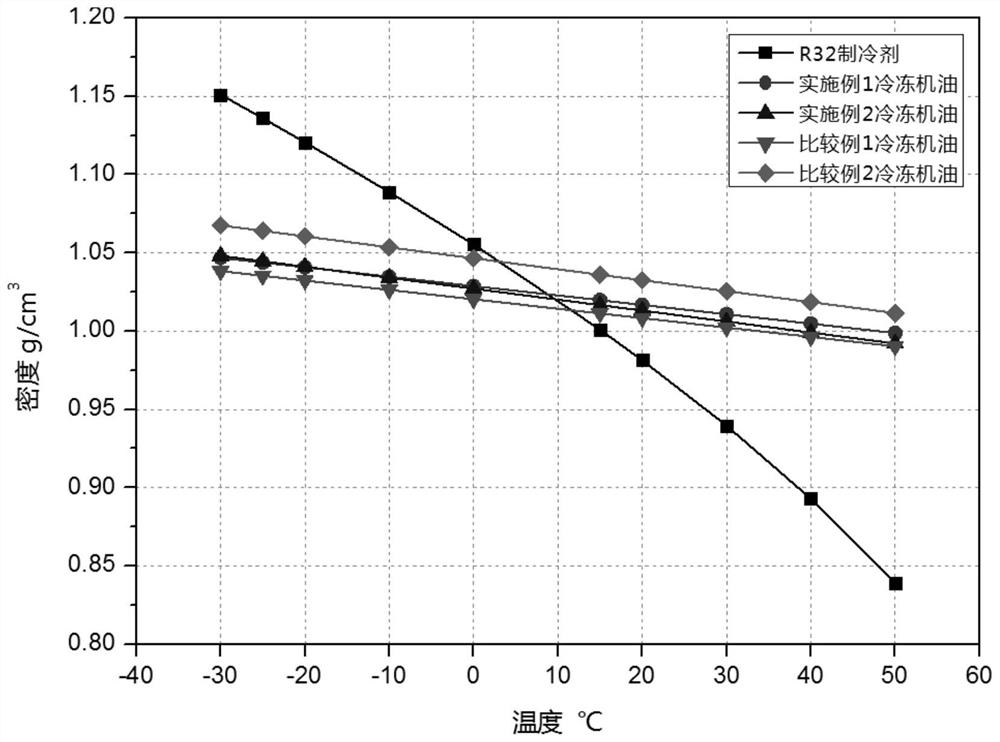

[0045] According to the stoichiometric ratio required by the esterification reaction to form a full ester, take an appropriate amount of dipentaerythritol, butyric acid, and 2-ethylhexanoic acid under the condition of a slight excess of acid, and obtain it after heating, water separation, reflux, and vacuum distillation Target base oil with a 1.1:1 molar ratio of butyric acid to 2-ethylhexanoic acid. The mass proportion of base oil in refrigeration oil is 97.5%, and the remaining 2.5% are additives, specifically 0.5% antioxidant, selected as 2,6-di-tert-butyl-4-cresol; 0.02% metal passivation 1% anti-wear agent, choose tricresyl phosphate; 0.98% acid scavenger, choose 2-ethylhexyl glycidyl ether, the above percentages are mass ratios .

Embodiment 2

[0047] According to the stoichiometric ratio required by the esterification reaction to generate the full ester, take an appropriate amount of pentaerythritol, isobutyric acid, adipic acid, and 3,5,5-trimethylhexanoic acid under the condition of a slight excess of acid, and heat, separate The target base oil was obtained after water, reflux, and vacuum distillation, wherein the molar ratio of isobutyric acid, adipic acid, and 3,5,5-trimethylhexanoic acid was 20:15:65. The total amount of base oil in refrigeration oil is 97.5%, and the remaining 2.5% are additives, specifically 0.5% antioxidant, which is 2, 6-di-tert-butyl-4-cresol; 0.02% metal passivation 1% anti-wear agent, choose tricresyl phosphate; 0.98% acid scavenger, choose pentaerythritol tetraglycidyl ether. The above percentages are mass ratios.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com