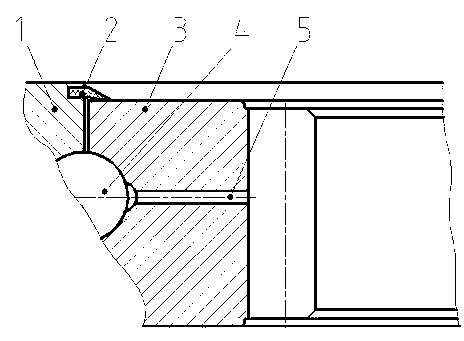

Slewing bearing with oil drainage holes

A technology of slewing bearings and oil drainage holes, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as difficulty, no stable discharge channel, danger, etc., to increase gear lubrication and reduce manual handling of gear lubrication problems The effect of the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] Example: Design the gear oil drain hole for a slewing bearing with a raceway diameter of more than 2.5 meters. The previous product has two disadvantages in lubrication. In the case, the oil drain hole design is done, the number of teeth is 120, and 15 oil drain holes with a diameter of φ8 are designed, and there is one in the middle of every 8 teeth. The slewing bearing with added oil discharge holes solves the shortcomings of grease overflow and the inability to add lubricating oil later.

[0014] The invention rationally utilizes the grease, increases the lubrication of the teeth, reduces the probability of manually dealing with the gear lubrication problem, and solves the problem that the gear cannot be lubricated with oil and grease at the later stage of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com