Water-based automobile plate stamping oil as well as preparation method and use method thereof

A technology of stamping oil and automobile, which is applied in the field of stamping oil, and can solve the problems that oily stamping oil is not easy to clean and affects the cleaning process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned water-based stamping oil for automobile sheet is simple to operate, and the obtained water-based stamping oil for automobile sheet has excellent application effect. The preparation method comprises the following steps:

[0036] Mix the antirust agent, water and alkali, and stir until completely dissolved to obtain a mixed solution;

[0037] Add base oil, oleic acid, synthetic ester, surfactant and fungicide into the mixed solution and stir evenly.

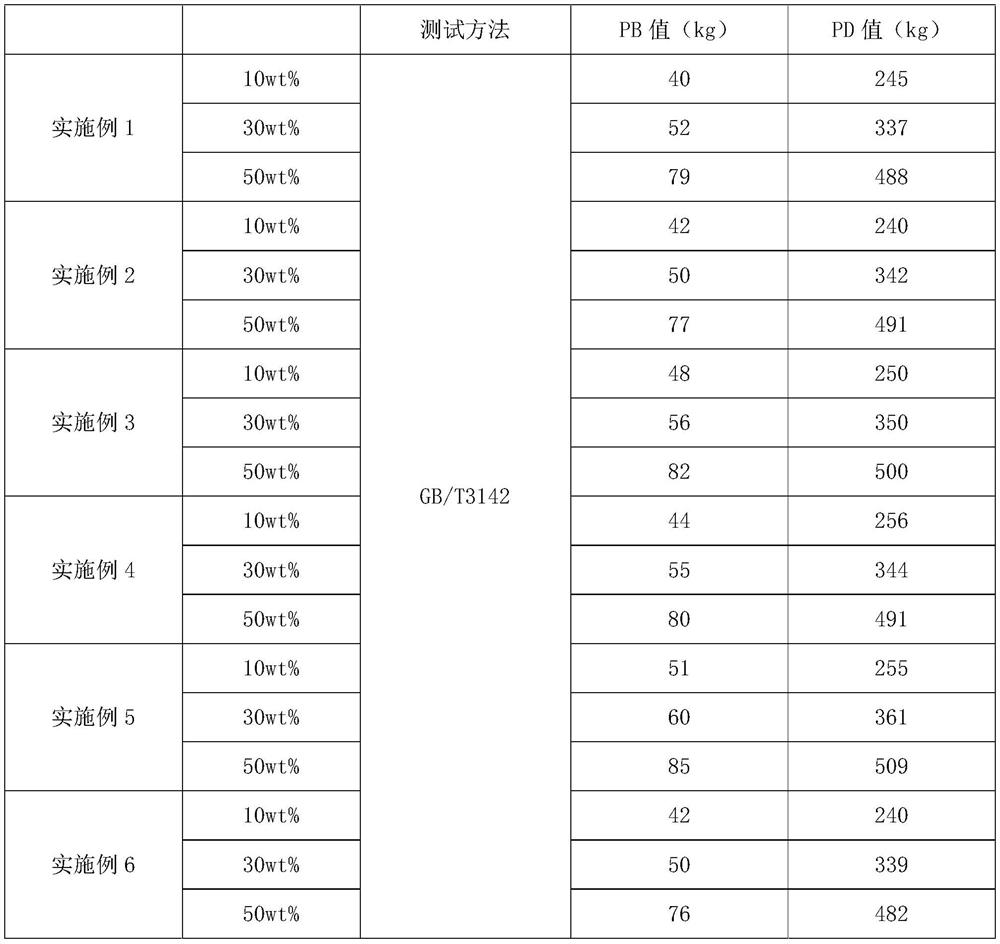

[0038] When using the above-mentioned water-based automotive sheet stamping oil, use water to dilute the water-based automotive sheet stamping oil to an appropriate concentration. According to the thickness of the water-based automotive sheet, the mass concentration of the water-based automotive sheet stamping oil is as follows:

[0039] For the stamping and stretching of the water-based automobile sheet with a thickness of 0.6mm-1.0mm, the use concentration of the water-based au...

Embodiment 1

[0046] The total weight portion of the water-based automobile plate stamping oil of the present embodiment is 100 parts, including the following parts by weight:

[0047] Base oil: 20 parts of 60N paraffin base oil;

[0048] 5 parts of oleic acid;

[0049] Synthetic ester: 10 parts of trimethylolpropane oleate;

[0050] Surfactant: 5 parts of a mixture of AEO9 fatty alcohol polyoxyethylene ether and sodium petroleum sulfonate;

[0051] Alkali: 5 parts of triethanolamine;

[0052] Antirust agent: 5 parts of dodecane dibasic acid antirust agent;

[0053] 1 part of BK fungicide;

[0054] 49 parts of water.

[0055] The preparation method of above-mentioned water-based automobile plate stamping oil comprises the following steps:

[0056] Mix the antirust agent, water and alkali, and stir until completely dissolved to obtain a mixed solution;

[0057] Add base oil, oleic acid, synthetic ester, surfactant and fungicide into the mixed solution and stir evenly.

[0058] When usi...

Embodiment 2

[0063] The total weight portion of the water-based automobile plate stamping oil of the present embodiment is 100 parts, including the following parts by weight:

[0064] Base oil: 30 parts of 100N paraffin base oil;

[0065] 10 parts of oleic acid;

[0066] Synthetic ester: 10 parts of trimethylolpropane oleate;

[0067] Surfactant: 10 parts of isomeric alcohol polyoxyethylene ether;

[0068] Alkali: 10 parts of monoethanolamine;

[0069] Antirust agent: 10 parts of sodium sebacic acid antirust agent;

[0070] 3 parts of MBM fungicide;

[0071] 12 parts of water.

[0072] The preparation method of above-mentioned water-based automobile plate stamping oil comprises the following steps:

[0073] Mix the antirust agent, water and alkali, and stir until completely dissolved to obtain a mixed solution;

[0074] Add base oil, oleic acid, synthetic ester, surfactant and fungicide into the mixed solution and stir evenly.

[0075] When using the above-mentioned water-based aut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com