Polyimide base high temp.-resistant and radiation-resistant lubricating paint

A technology of polyimide base and polyimide resin, which is applied in the direction of coating, etc., can solve the problems of high temperature resistance and insufficient radiation resistance, and achieve excellent high temperature resistance, radiation resistance and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

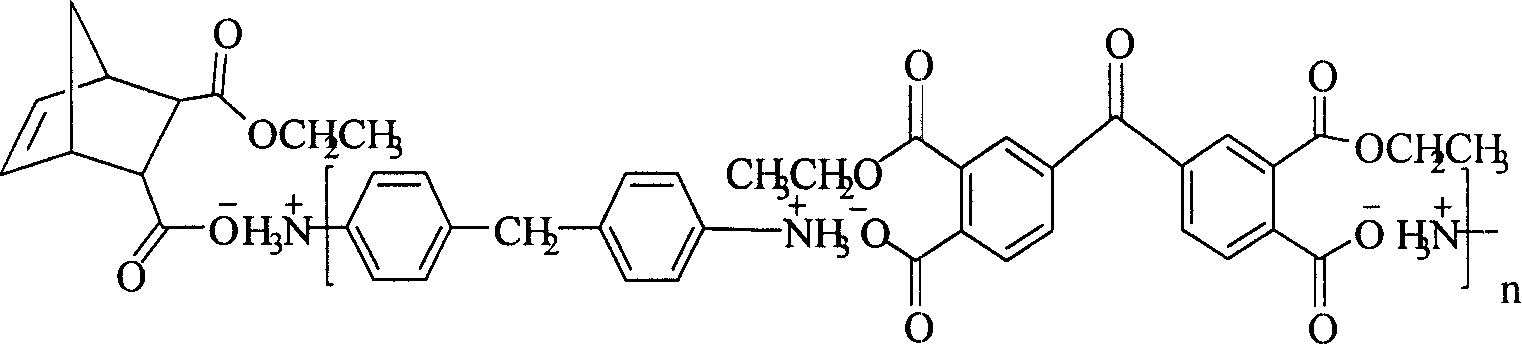

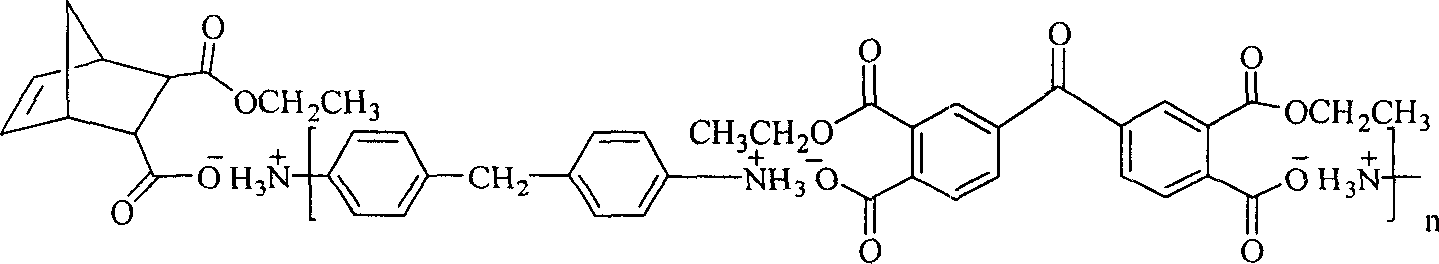

Image

Examples

Embodiment 1

[0023] Weigh 4.0 grams of polyimide resin and stir it in 3.0 grams of mixed solvent to dissolve it; weigh 1.7 grams of molybdenum disulfide, 0.2 grams of antimony trioxide, and 0.2 grams of basic lead phosphite into a ball mill tank , add 3.0 grams of mixed solvent and ball mill for 5 hours, disperse to the required particle size, add polyimide resin and grind for half an hour; add 8.0 grams of mixed solvent after discharging, and disperse evenly to obtain polyimide-based lubricating protective coating [ Mixed solvent (volume percentage): N, N dimethylacetamide: 66%, toluene: 34%].

Embodiment 2

[0024] Embodiment 2: (unit: gram)

[0025] Polyimide resin 4.0 Molybdenum disulfide 1.67

[0026] Antimony trioxide 0.4 Basic lead phosphite 0.32

[0027] Mixed solvent 11 [wherein: N,N dimethylacetamide: 60%, toluene: 40% (volume percentage)].

Embodiment 3

[0028] Embodiment 3: (unit: gram)

[0029] Polyimide resin 4.0 Molybdenum disulfide 1.78

[0030] Antimony trioxide 0.38 Basic lead phosphite 0.42

[0031] Mixed solvent 11 [wherein: N,N dimethylacetamide: 55%, toluene: 45% (volume percentage)].

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com