Polytetrafluoroethylene bonded solid lubricant

A polytetrafluoroethylene based, solid lubricant technology, used in lubricating compositions, additives, petroleum industry and other directions, can solve the problem of long service life, performance can not fully meet the requirements of screw type oil-free air compressor rotor supporting use, use Harsh working conditions and other problems, to achieve long wear life, low friction coefficient, good impact resistance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

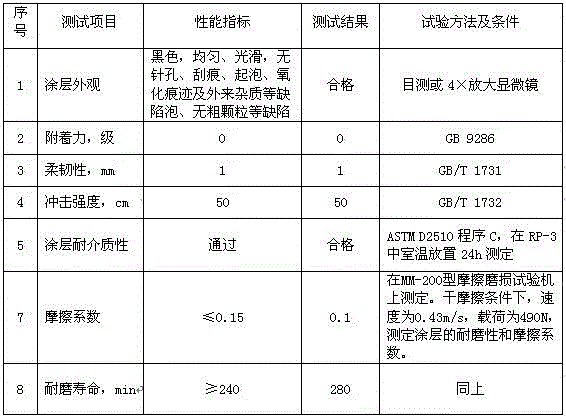

Image

Examples

Embodiment 1

[0027] Weigh 45.0g of polytetrafluoroethylene, 15.0g of melamine cyanurate (MCA), 10.0g of molybdenum disulfide, 9.0g of antimony trioxide, 3.0g of cerium fluoride and 4.0g of carbon black and pour them into a ball mill jar, add about 35 grams of organic thinner for grinding. Then add 270.0 grams of polyamide-imide resin, 24.3 grams of epoxy resin and 620 grams of diluent to disperse evenly to form a polytetrafluoroethylene-based bonded solid lubricant [diluent: 40% pyrrolidone, 40% dimethyl formamide , Xylene 20% (volume percentage composition)].

Embodiment 2

[0029] The preparation method is the same as in Example 1, and the mass percentage of the lubricant is composed of: 4.0% polytetrafluoroethylene, 2.0% melamine cyanurate (MCA), 1.2% molybdenum disulfide, 0.5% cerium fluoride, Antimony 1.2%, carbon black 0.4%, polyamideimide 9.0%, epoxy resin 2.0%, diluent balance [diluent (volume percentage composition: pyrrolidone 40%, dimethylformamide 40%, xylene 20%)].

Embodiment 3

[0031] The preparation method is the same as in Example 1, and the mass percentage of the lubricant is composed of: polytetrafluoroethylene 7.0%, melamine cyanurate (MCA) 2.0%, molybdenum disulfide 2.0%, cerium fluoride 0.3%, di Antimony 0.5%, carbon black 0.3%, polyamideimide 8.0%, epoxy resin 2.0%, diluent balance [thinner (volume percentage composition: pyrrolidone 40%, dimethylformamide 40%, xylene 20%)].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com