Magnetic fluid lubricating method based on tiny magnetic body array

A magnet array and magnetic fluid technology, applied in bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of limiting the effect of magnetic fluid lubrication and single magnetic field form, and achieve the effect of improving lubrication effect and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

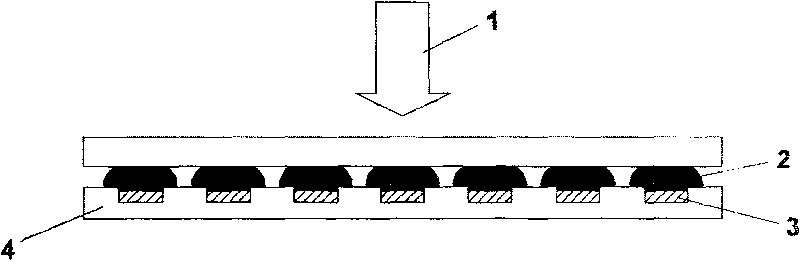

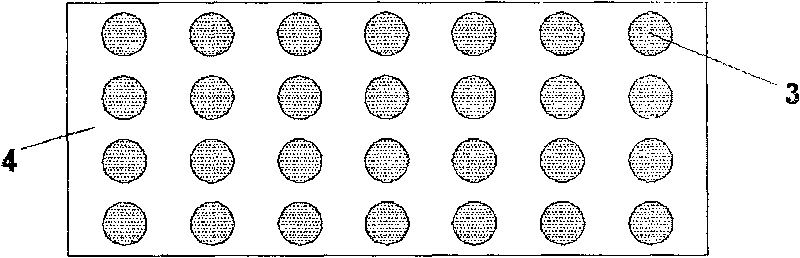

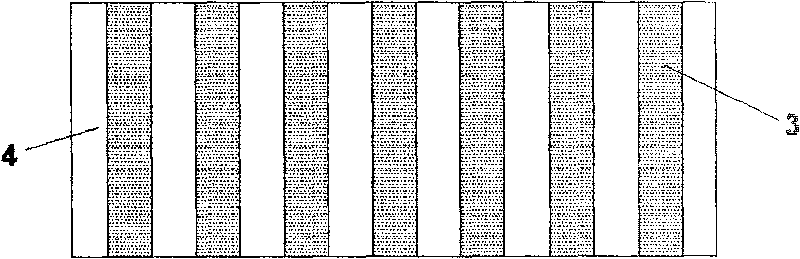

[0015] The drawings show an embodiment of the invention and the design of two magnet arrays therein. figure 1 It is a design diagram of a magnetohydrostatic support and lubrication system based on a micro-magnet array. The key to the implementation of this design is the fabrication of the tiny magnetic field array, which can be realized in the following way. First of all, choose the surface material of the friction pair, you can choose ferromagnetic material and non-ferromagnetic material. Ferromagnetic materials include electrical pure iron and ordinary carbon steel. Electrical pure iron is a good magnetic material, while ordinary carbon steel is also a ferromagnetic material and may have residual magnetism. Non-ferrous materials can use non-ferrous metals, silicon wafers and engineering plastics Such as PTFE and UHMWPE etc. Then, processing on the surface of the friction pair can further deposit micro-textures of magnetic materials, such as micro-scale pits (such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com