Intelligent lubricating system for marine engine

A marine engine and lubrication system technology, applied in the direction of lubricating components, lubricating indicator devices, pressure lubricating safety devices, etc., can solve the problem of particle size content, water content can not be judged, no online monitoring, automatic alarm and automatic control, Problems such as oil operating pressure and flow cannot be accurately measured, so as to ensure continuous and safe operation and make up for untimely effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

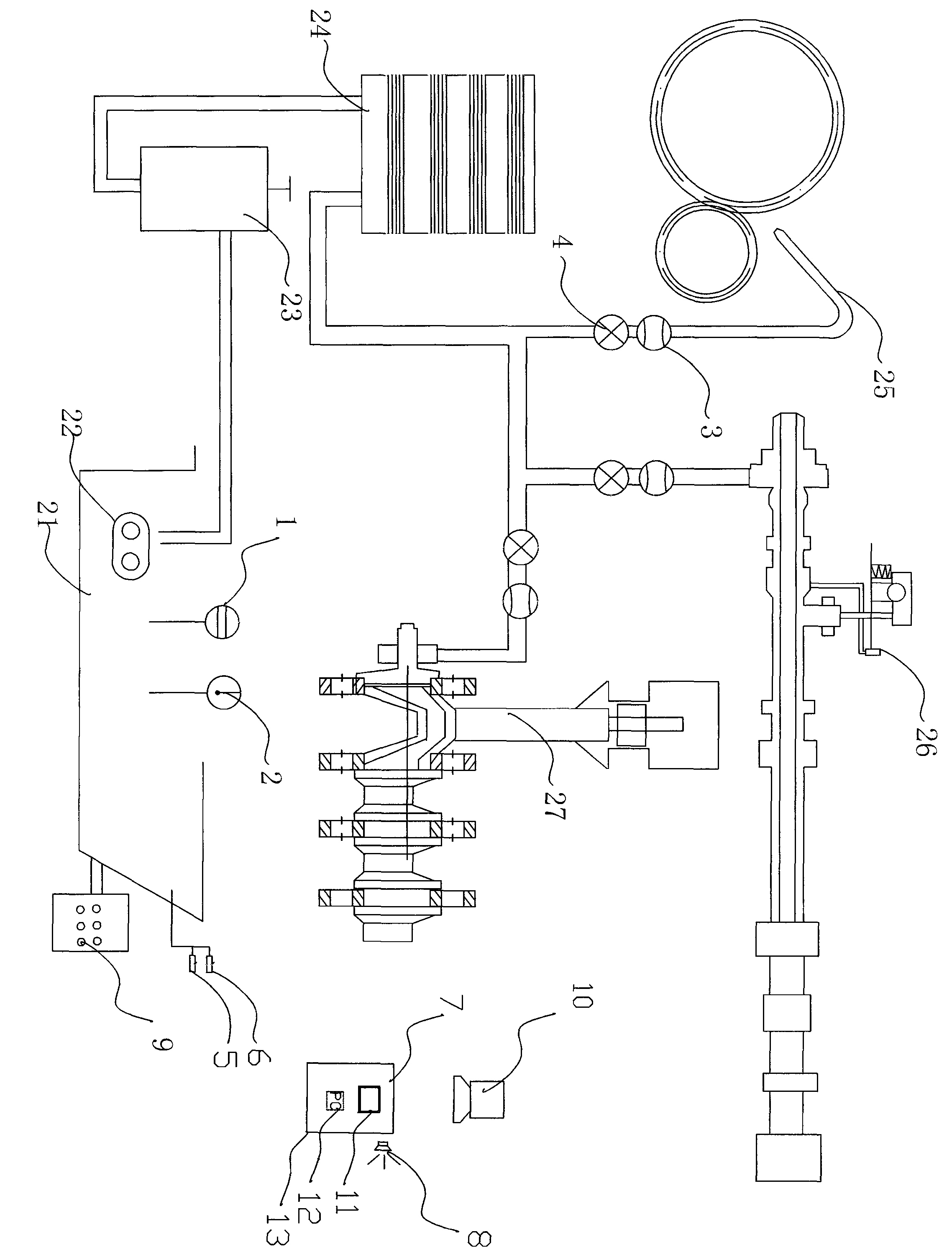

[0012] like figure 1 As shown, the marine engine intelligent lubrication system of this embodiment includes a temperature sensor 1, a liquid level gauge 2, a flow meter 3, a pressure sensor 4, a particle detector 5 in oil, a moisture detector 6 in oil, and a data acquisition and processing unit. 7. The alarm device 8, the automatic oil purifier 9, and the upper computer 10 are connected to each other by wire (or wireless communication), wherein the temperature sensor 1 and the liquid level gauge 2 are arranged on the oil tank 21, and the flow meter 3 and the pressure sensor 4 are arranged on the ship engine. On the oil pipeline of the lubricating point, the oil particle detector 5 and the oil moisture detector 6 are arranged outside the oil tank and are connected to the oil tank pipe. The alarm device 8 is arranged at a suitable position on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com