Double-nozzle gas/liquid dual-fuel in-cylinder direct injection internal combustion engine and control method

An in-cylinder direct injection, dual-fuel technology, applied in fuel injection control, electrical control, engine control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

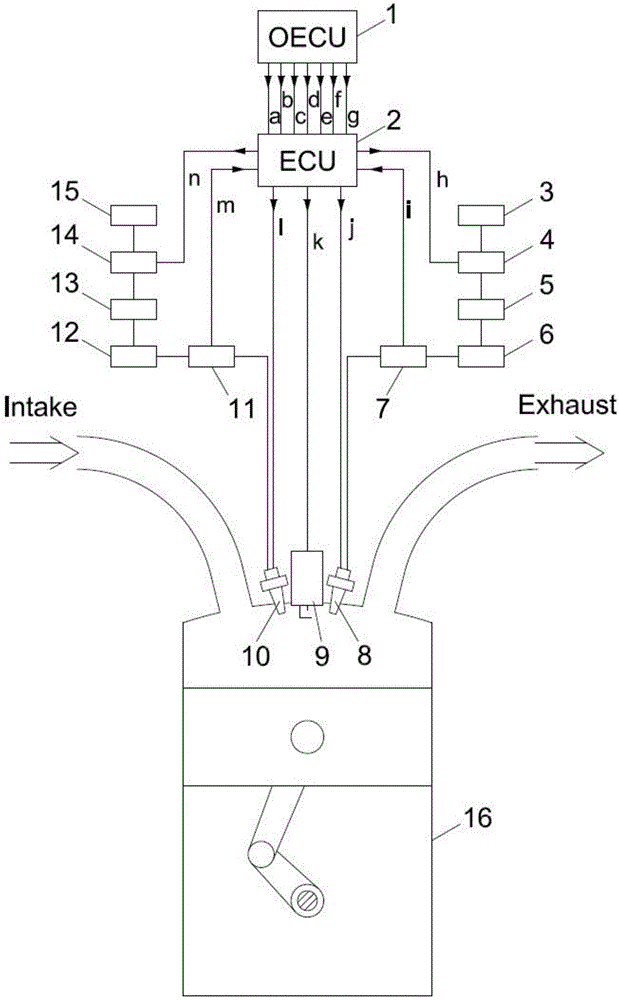

[0036] like figure 1 As shown, a dual-nozzle gas / liquid dual-fuel in-cylinder direct-injection internal combustion engine in this embodiment, on the basis of continuing to use the ignition type internal combustion engine main body (16), spark plug (9) and the original machine electronic control unit (1), A set of dual-nozzle gas / liquid dual-fuel in-cylinder direct injection system and an injection and combustion electronic control unit (2) are added;

[0037] The set of dual-nozzle gas / liquid dual-fuel in-cylinder direct injection system is characterized in that it includes: gas fuel tank (3), gas fuel control valve (4), gas fuel regulator (5), gas fuel Booster pump (6), gas fuel flow and rail pressure sensor (7), gas fuel nozzle (8), liquid fuel tank (15), liquid fuel control valve (14), liquid fuel primary booster pump (13) , liquid fuel secondary pressure pump (12), li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com