Drum-type gear with oil supply and lubrication functions

A technology of drum-shaped teeth and gears, applied in the direction of components with teeth, gear lubrication/cooling, belts/chains/gears, etc. The effect of dynamic pressure bearing performance, enhanced capillary driving force, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

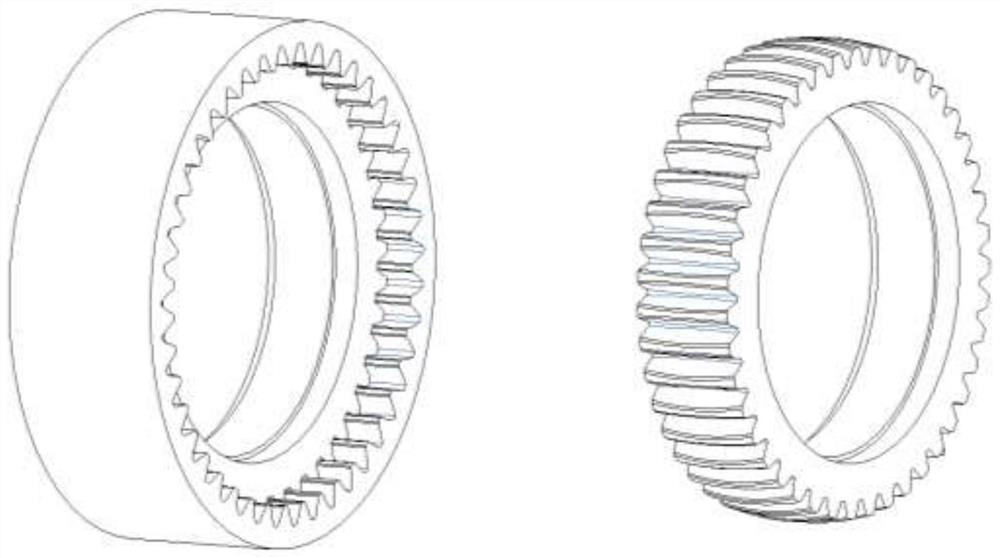

[0027] From figure 2 It can be seen that a drum gear with an oil supply lubrication function in the present invention includes a gear base 1, drum teeth 2, microporous grooves 3, shaft holes 4, and keyway holes 5; drum teeth 2 and gear base 1 are one On the whole, the micro-hole groove 3 is opened on the tooth surface of the drum-shaped tooth 2 , the shaft hole 4 is opened at the center of the gear base 1 , and the keyway hole 5 is opened on the inner wall of the shaft hole 4 .

[0028] Wherein, the shaft hole 4 is used for installing the transmission shaft, and the keyway hole 5 is used for positioning between the gear and the transmission shaft. The tooth end surface of the drum-shaped tooth 2 is an involute tooth profile, and the tooth axially bulges outward from the middle position.

[0029] The microporous groove 3 has a drainage function, that is, during the start-up stage and working process of the drum gear, the oil supply on the end surface of the external gear can ...

Embodiment 2

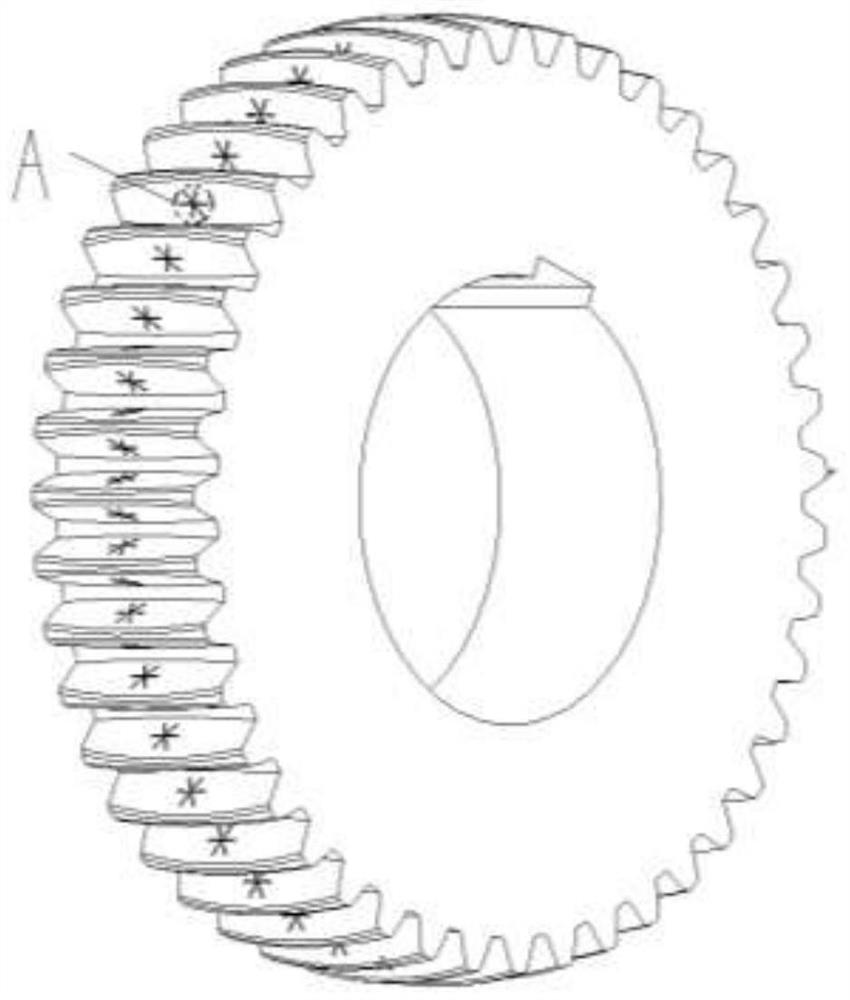

[0031] From image 3 It can be seen that the drum gear with oil supply and lubrication function of the present invention: the microporous grooves 3 are evenly opened on the contact area of the front and rear two tooth surfaces of each tooth of the drum gear 2, and the number of microporous grooves 3 on each tooth surface 6 to 12.

[0032] The microporous grooves 3 are provided on both sides of the tooth surface contact area of the drum gear, and the tooth surface contact area of the drum gear refers to the part where the middle part of the tooth surface of the drum gear 2 bulges outward. With the development of metallurgical machinery and equipment towards high speed and heavy load, the contact stress between the contact interfaces of drum gears is relatively large, and the contact interfaces must be fully lubricated. Therefore, the microporous grooves on the single side of each tooth of the drum gear 2 The number of three is 6 to 12, thus ensuring the lubricating effec...

Embodiment 3

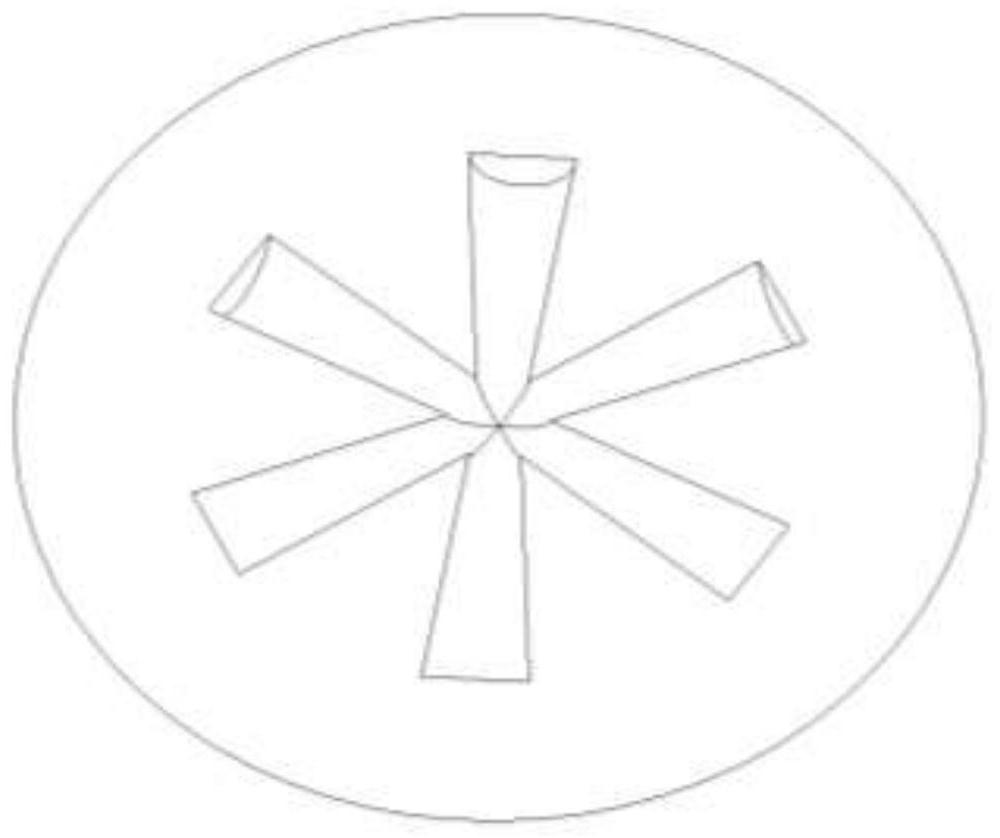

[0034] From image 3 It can be seen that the present invention has a drum gear with oil supply lubrication function: the microporous grooves 3 are distributed in a circular array on the contact area of the tooth surface, and each microporous groove transitions from the outer edge to the center in a tapered shape from large to small.

[0035] The tapered shape of the microporous groove 3 from large to small further improves the capillary driving force and forms a wedge-shaped converging space. The circular array distribution of microporous grooves 3 and the conical structure make the lubricating oil flow from both ends of the gear to the center, so that the oil reaches the contact area, and at the same time form a wedge-shaped convergence space, which enhances the dynamic pressure bearing capacity of the lubricating oil film and improves the lubrication quality. The oil flow condition between the contact interfaces of the gear pairs is improved, the heat in the meshing area i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com