Equipment maintenance prompt system

A technology for equipment maintenance and equipment, which is applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as damage to on-site operating equipment, and achieve the effects of improving equipment lubrication quality, accurate measurement, and precise maintenance time points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

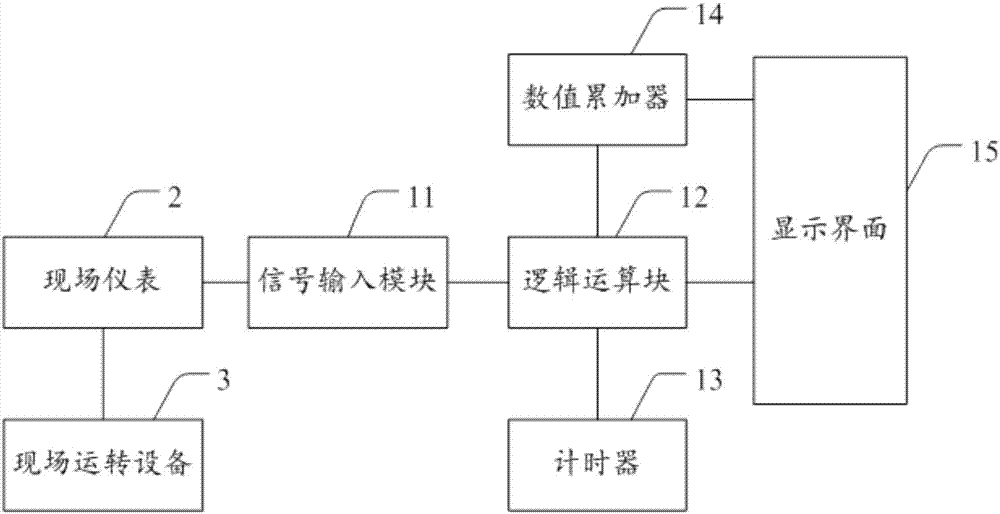

[0020] refer to figure 1 As shown, the embodiment of the present invention provides an equipment maintenance reminder system, including: a signal input module 11 , a logic operation block 12 , a timer 13 and a value accumulator 14 .

[0021] The signal input module 11 is connected with the logic operation block 12 , the timer 13 is connected with the logic operation block 12 , and the value accumulator 14 is connected with the logic operation block 12 .

[0022] The signal input module 11 is used for obtaining a state signal representing the current state of the field operation equipment 3 from the field instrument 2 .

[0023] It should be noted that, in the implementation of the present invention, the on-site operating equipment 3 is equipment that needs to replenish lubricating oil to the bearing parts. Specifically, the on-site operating equipment 3 refers to pumps, motors, and the like. The field instrument 2 is an instrument for measuring various process parameters of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com