Minimal quantity lubrication system applied to facing-type cutter

A micro-lubrication, face milling cutter technology, used in measuring/indicating equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as difficulty in uniform lubrication, increased tool wear, loss of nozzle flow, etc. Insufficient and excessive lubrication, improved lubrication quality, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of this patent application will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

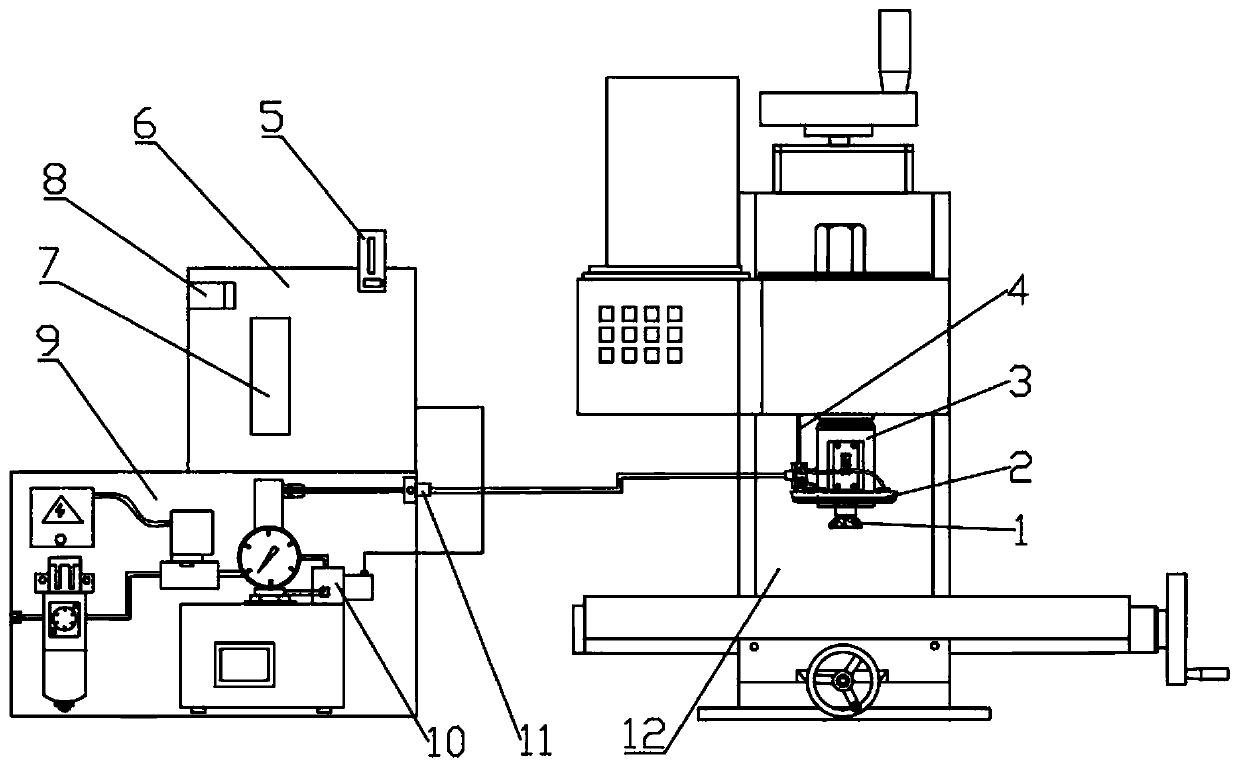

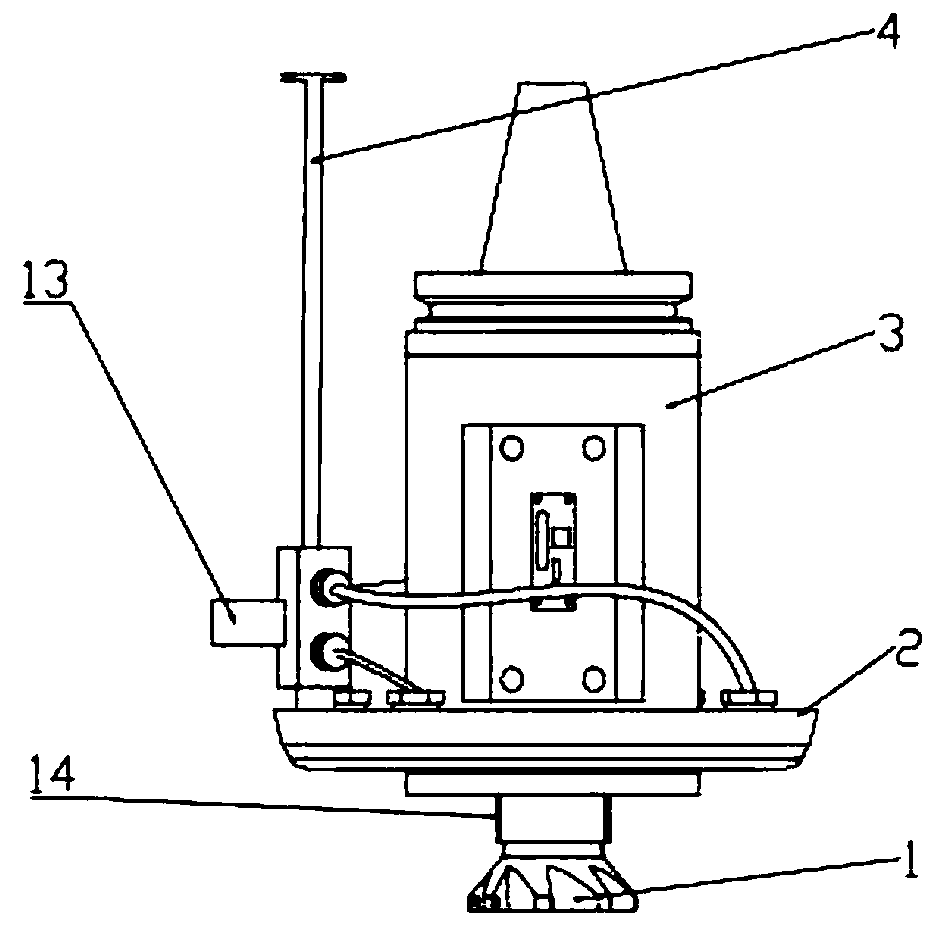

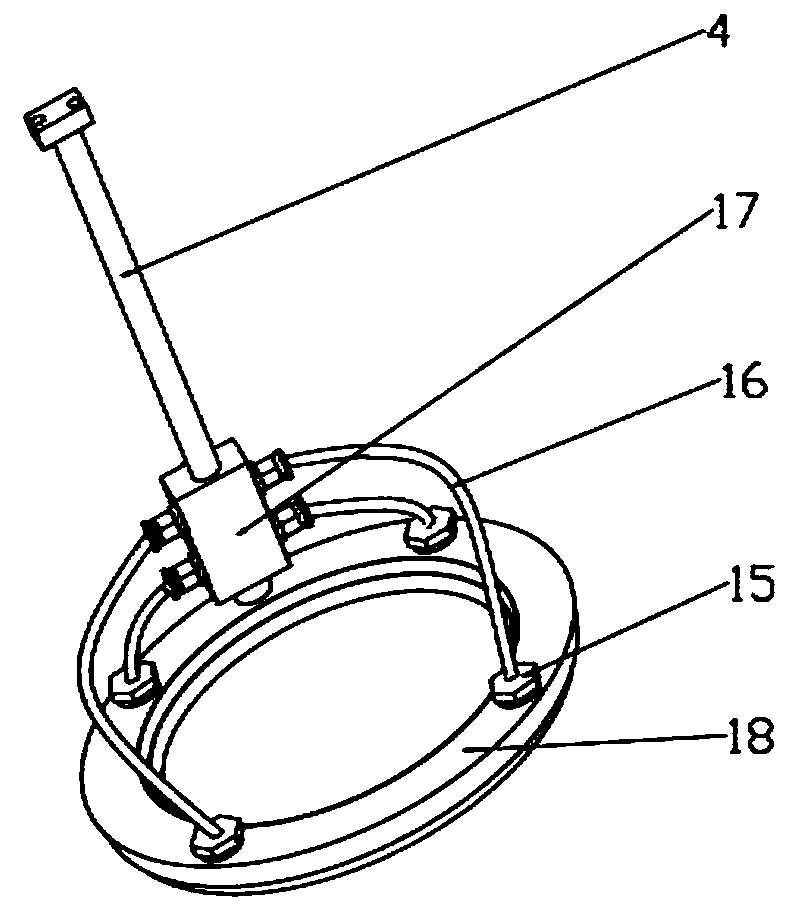

[0029] Such as figure 1 A minimal quantity lubrication system applied to a shell face milling cutter is shown, which mainly includes: an annular minimum quantity lubrication nozzle 2 fixed on a milling machine 12, a wireless temperature measuring mechanism 3 arranged on a cutter bar of a shell face milling cutter 1 and A single-chip microcomputer control system 6 that receives wireless temperature measurement data from the wireless temperature measurement mechanism 3 and controls the lubrication flow rate of the annular micro-lubrication nozzle. Preferably, an electromagnetic valve 10 is set on the minimum quantity lubrication oil supply circuit and controlled by a single-chip microcomputer control system 6 . The single-chip microcomputer control system 6 includes a single-chip microcomputer 7 and a wirele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com