A high-strength hot-dip galvanized strap and its production method

A hot-dip galvanizing, high-strength technology, applied in hot-dip galvanizing, flexible slender elements, coatings, etc. The effect of shortening the process and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below:

[0038] Table 1 is the value list of the chemical components of each embodiment of the present invention and comparative examples;

[0039] Table 2 is the rolling process parameter list of each embodiment of the present invention and comparative example;

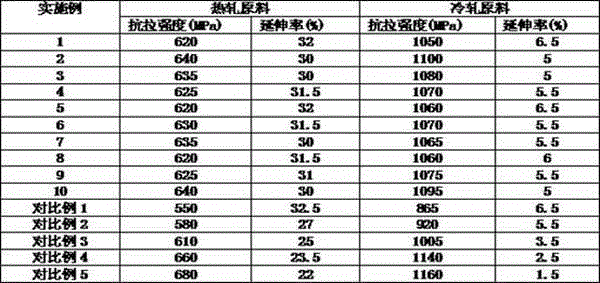

[0040] Table 3 is the testing situation list of the raw material mechanical properties of each embodiment of the present invention and comparative examples;

[0041] Table 4 is the tape making process parameter and product performance detection situation list of each embodiment of the present invention and comparative example;

[0042] Table 5 is a list of performance conditions of each embodiment of the present invention and comparative examples.

[0043] Each embodiment of the present invention is produced according to the following steps:

[0044] 1) After smelting and continuous casting, the slab is heated conventionally;

[0045] 2) Carry out rough rolling, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com