Super-thick high-strength lamellar-tearing-resistant Q500D-Z35 hydroelectric generating set steel plate and manufacturing method thereof

A Q500D-Z35, anti-lamellar tearing technology, applied in the field of metallurgy, can solve the problems of high welding performance requirements, difficulty in increasing the performance of steel plates, low CEV of steel plates, etc. The effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

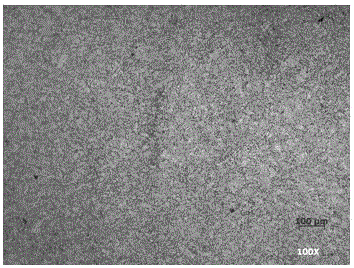

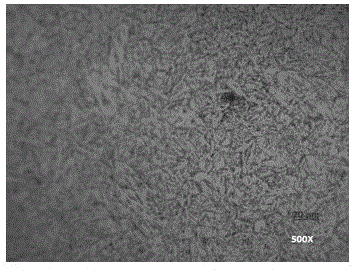

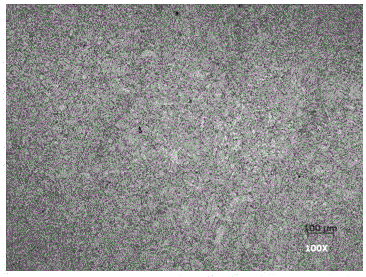

Image

Examples

Embodiment 1

[0096] The grade of steel in this embodiment is Q500D-Z35, the thickness of the steel plate is 265mm, and the single weight of the steel plate is 45t. It is smelted from the following components in mass percentage, C: 0.14%, Si: 0.35%, Mn: 0.98%, P: 0.008%, S: 0.001%, Ni: 1.02%, Cr: 0.62%, Mo: 0.50%, Cu: 0.28%, Nb: 0.029%, Al: 0.030%, Ti: 0.022%, V: 0.002%, Ca: 0.0015%, B: 0.0003%, and the balance is Fe and unavoidable impurities.

[0097] The steps of the Q500D-Z35 steel plate production method of the present embodiment are ultra-thick, high-strength, and resistant to lamellar tearing are as follows:

[0098] Step (1) Determine the size of the steel ingot and the forging billet. The steel ingot is a quincunx ingot, the nominal weight of the steel ingot is 70t, the thickness of the steel billet after forging is 880mm, the width is 2100mm, and the length is 3900mm.

[0099] Step (2) initial smelting, the primary smelting is carried out in the EAF electric arc furnace, and the ...

Embodiment 2

[0121] The grade of steel in this embodiment is Q500D-Z35, the thickness of the steel plate is 325mm, and the single weight of the steel plate is 34t. It is smelted from the following components in mass percentage, C: 0.15%, Si: 0.45%, Mn: 0.90%, P: 0.006%, S: 0.001%, Ni: 1.22%, Cr: 0.59%, Mo: 0.55%, Cu: 0.26%, Nb: 0.032%, Al: 0.029%, Ti: 0.020%, V: 0.002%, Ca: 0.0020%, B: 0.0003%, and the balance is Fe and unavoidable impurities.

[0122] The steps of the Q500D-Z35 steel plate production method of the present embodiment are ultra-thick, high-strength, and resistant to lamellar tearing are as follows:

[0123] Step (1) Determine the size of the steel ingot and the forging billet. The steel ingot is a quincunx ingot, the nominal weight of the steel ingot is 60t, and the thickness of the steel billet after forging is 1020mm, the width is 1600mm, and the length is 3900mm.

[0124] Step (2) preliminary refining, the preliminary refining is carried out in the EAF electric arc furn...

Embodiment 3

[0146] The grade of steel in this embodiment is Q500D-Z35, the thickness of the steel plate is 210mm, and the single weight of the steel plate is 29t. It is smelted from the following components in mass percentage, C: 0.12%, Si: 0.29%, Mn: 1.02%, P: 0.006%, S: 0.001%, Ni: 0.90%, Cr: 0.67%, Mo: 0.45%, Cu: 0.20%, Nb: 0.025%, Al: 0.029%, Ti: 0.022%, V: 0.002%, Ca: 0.0010%, B: 0.0002%, and the balance is Fe and unavoidable impurities.

[0147] The steps of the Q500D-Z35 steel plate production method of the present embodiment are ultra-thick, high-strength, and resistant to lamellar tearing are as follows:

[0148] Step (1) Determine the size of the steel ingot and the forging billet. The steel ingot is a quincunx ingot, the nominal weight of the steel ingot is 50t, the thickness of the steel billet after forging is 810mm, the width is 2100mm, and the length is 3900mm.

[0149] Step (2) initial refining, the initial refining is carried out in the EAF electric arc furnace, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com