Rotary tillage, ditching, fertilizing, sowing, compacting and spraying multi-functional drought direct seeding machine

A dry direct seeding, multi-functional rice technology, applied in the direction of excavation/covering of trenches, planting methods, agricultural machinery and implements, etc. Achieve the effect of improving the cavitation rate and utilization rate, the relative position design is reasonable, and the production economy is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

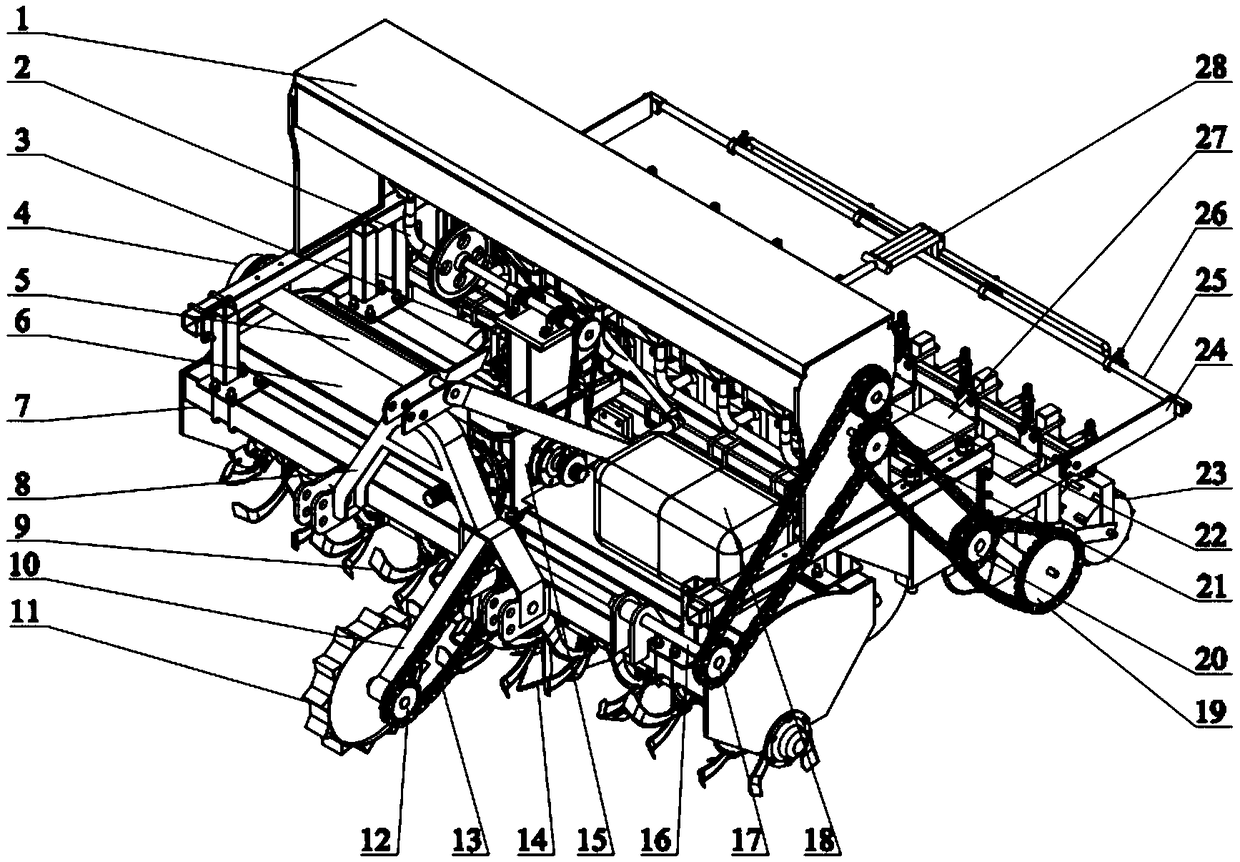

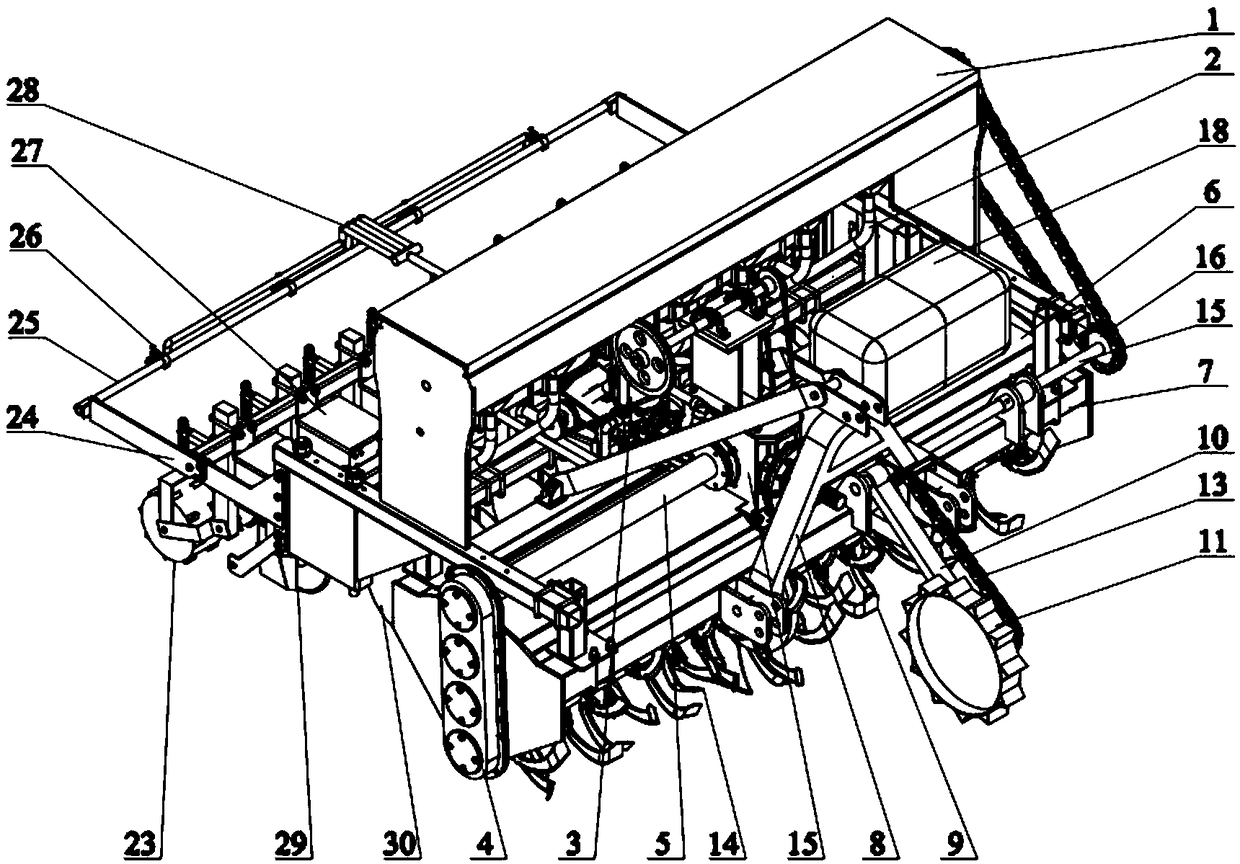

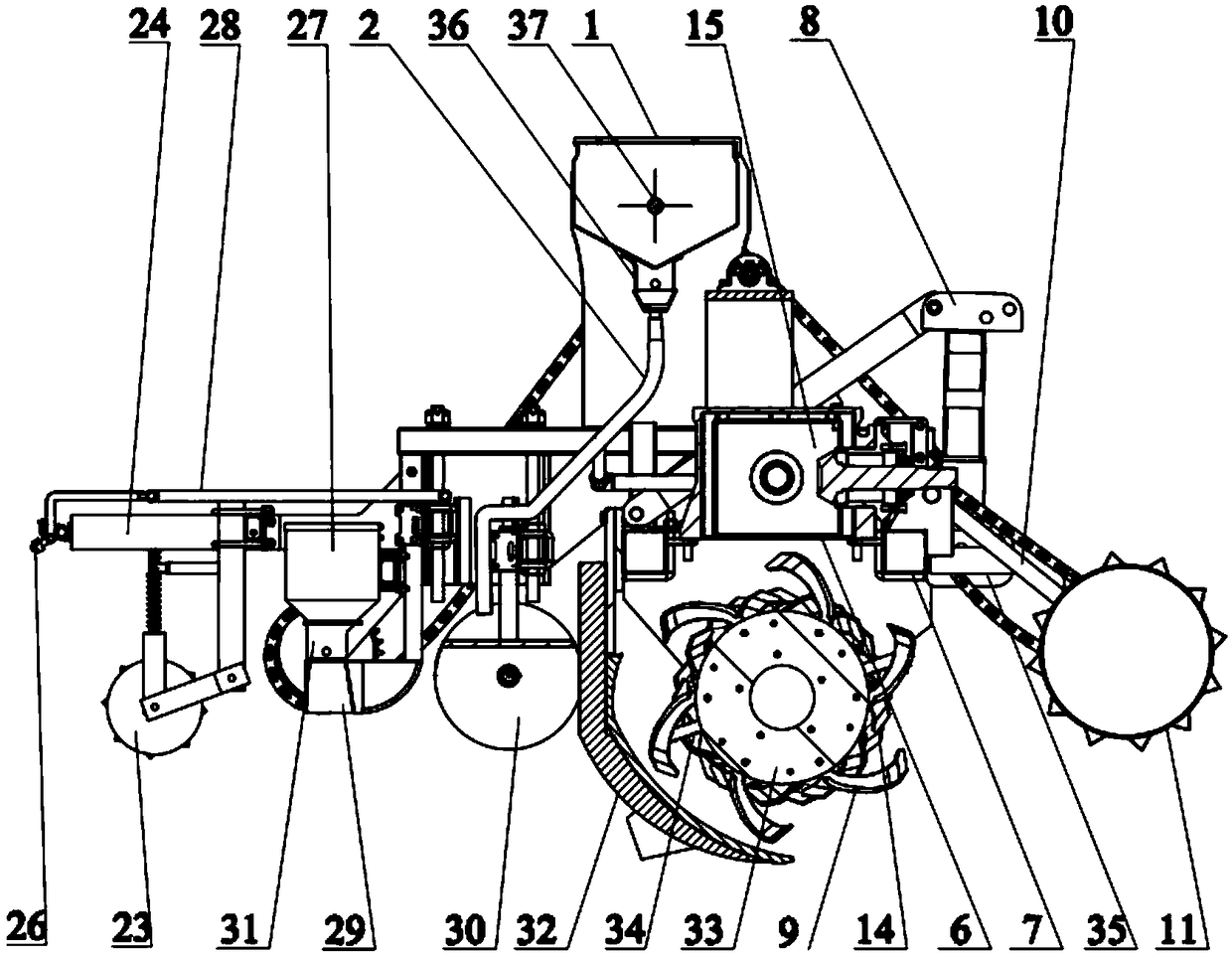

[0039] See attached picture.

[0040] The present invention will be further described below in conjunction with the accompanying drawings and examples, but these examples should not be construed as a limitation of the present invention.

[0041] This example provides a kind of rotary tillage, ditching, fertilization, seeding, suppression and spraying multifunctional rice dry direct seeding machine, including frame 7, three-point suspension device, gearbox 15, ground wheel driving device, rotary tillage device, ditching device, and fertilization device , sowing device, suppressing device, spraying device, a three-point suspension device is installed in the middle of the front of the frame, a ground wheel driving device is installed in the middle of the front of the frame 7, and a cover 6 is provided on the frame 7. A rotary tiller and a ditching device are installed under the cover 6, and the ditching device is arranged in the middle of the rotary tiller and cooperates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com