Electric conductivity adjustable organic molecular film and semiconductor hybrid material and preparation method thereof

A technology of organic molecules and conductive properties, applied in the field of preparation of organic molecular films and semiconductor hybrid materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

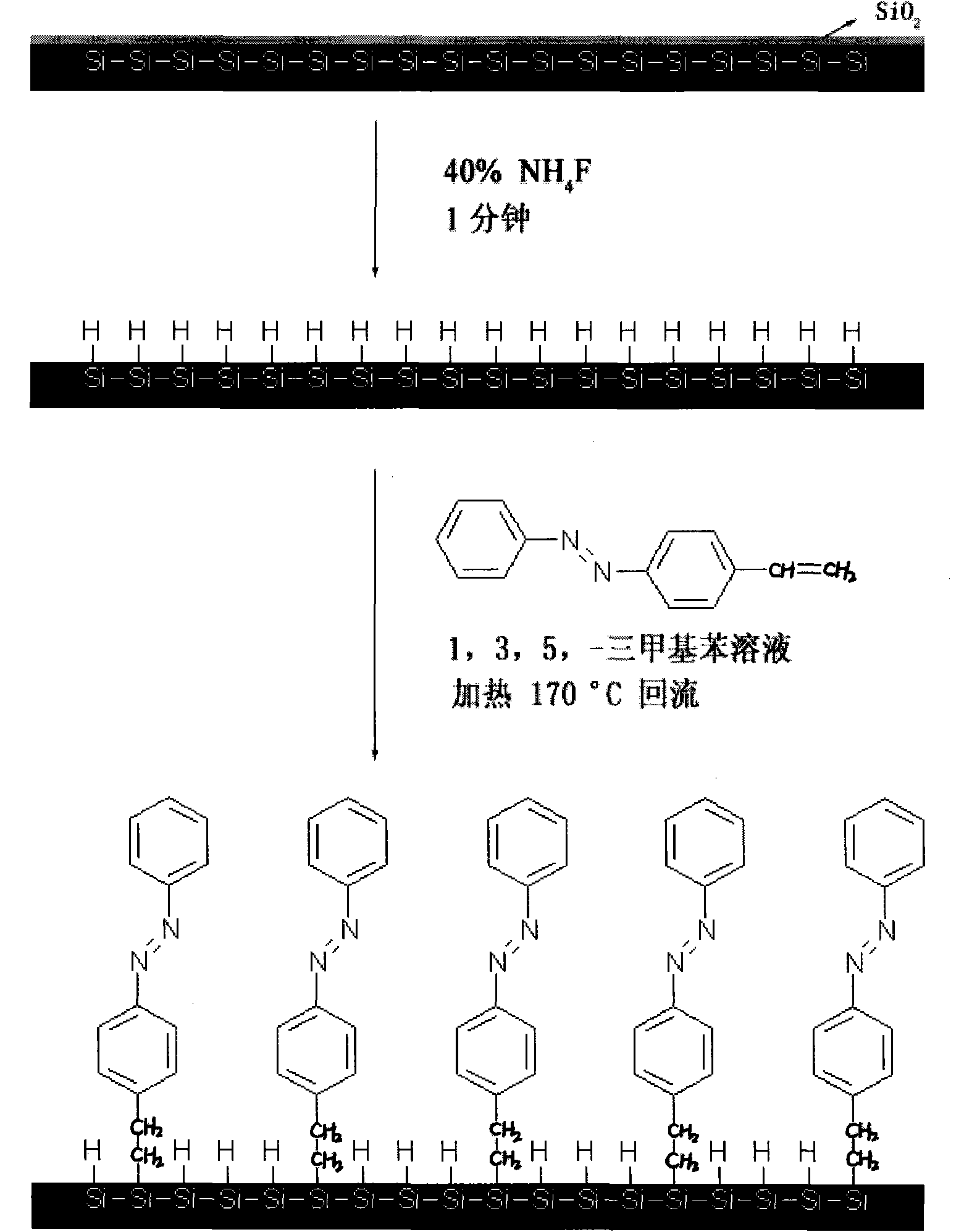

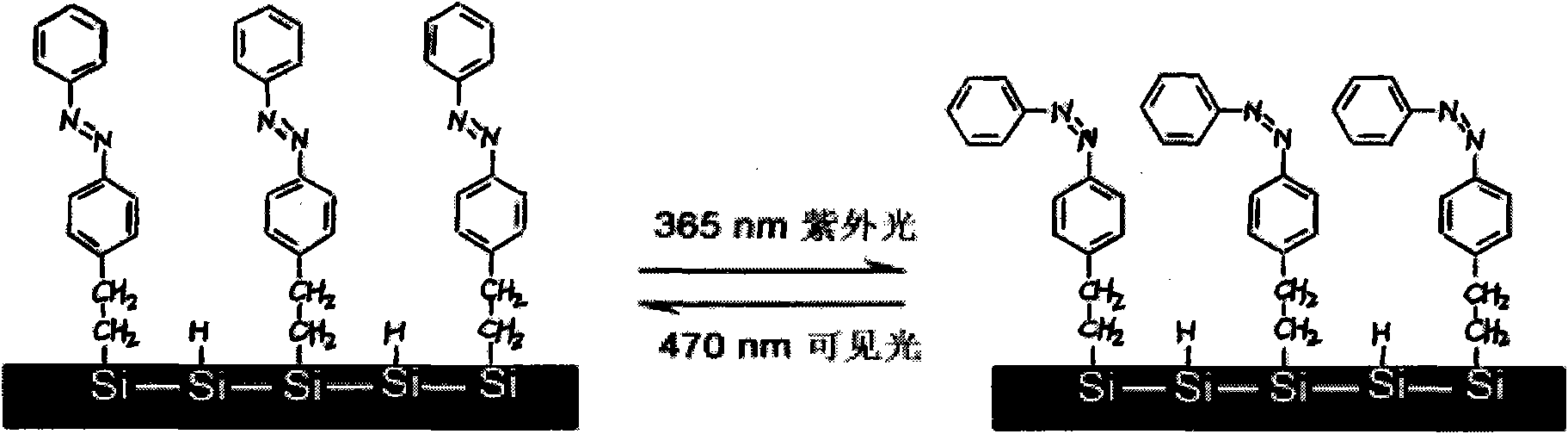

Method used

Image

Examples

Embodiment 1

[0074] (1) Cleaning of the monocrystalline silicon semiconductor substrate: the monocrystalline silicon semiconductor substrate with the crystal form being (111) was cleaned successively with acetone and methane for 15 minutes; then placed in concentrated sulfuric acid with a mass concentration of 98% and In a mixture of 30% hydrogen peroxide, keep it at a temperature of 90°C for 50 minutes, take it out and use a resistivity > 18MΩcm -1 Fully cleaned with ultrapure water, wherein the volume ratio of concentrated sulfuric acid with a mass concentration of 98% and hydrogen peroxide with a mass concentration of 30% is 3:1;

[0075] (2) Pretreatment of the monocrystalline silicon semiconductor substrate: soak the cleaned monocrystalline silicon semiconductor substrate of the crystal type (111) obtained in step (1) in an aqueous ammonium fluoride solution with a mass concentration of 30% for 60 seconds to remove The oxide layer of the monocrystalline silicon semiconductor substrate...

Embodiment 2

[0086] (1) Cleaning of the monocrystalline silicon semiconductor substrate: the monocrystalline silicon semiconductor substrate with the crystal form being (100) was cleaned successively with acetone and methane for 15 minutes; In a mixture of 30% hydrogen peroxide, keep it at 100°C for 40 minutes, take it out and use a resistivity > 18MΩcm -1 Fully cleaned with ultrapure water, wherein the volume ratio of concentrated sulfuric acid with a mass concentration of 98% and hydrogen peroxide with a mass concentration of 30% is 3:1;

[0087] (2) Pretreatment of the monocrystalline silicon semiconductor substrate: soaking the cleaned monocrystalline silicon semiconductor substrate of crystal type (100) obtained in step (1) in 1% hydrofluoric acid aqueous solution for 2 minutes to remove The oxide layer of the monocrystalline silicon semiconductor substrate; the prepared substrate is placed in an oxygen-free environment and sealed for storage;

[0088] (3) Configure an organic molecu...

Embodiment 3

[0098](1) Cleaning of the monocrystalline silicon semiconductor substrate: the monocrystalline silicon semiconductor substrate with the crystal form being (111) was cleaned successively with acetone and methane for 15 minutes; then placed in concentrated sulfuric acid with a mass concentration of 98% and In a mixture of 30% hydrogen peroxide, keep it at a temperature of 90°C for 55 minutes, take it out and use a resistivity > 18MΩcm -1 Fully cleaned with ultrapure water, wherein the volume ratio of concentrated sulfuric acid with a mass concentration of 98% and hydrogen peroxide with a mass concentration of 30% is 3:1;

[0099] (2) Pretreatment of the monocrystalline silicon semiconductor substrate: soaking the cleaned monocrystalline silicon semiconductor substrate of the crystal type (111) obtained in step (1) in an aqueous ammonium fluoride solution with a mass concentration of 15% for 90 seconds to remove The oxide layer of the monocrystalline silicon semiconductor substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com