Heating process for sulfuric acid leaking point corrosion resisting band steel

A heating process and sulfuric acid-resistant technology, applied in the field of steel rolling, can solve problems such as corrosion of high-alloy steel, and achieve the effects of uniform billet performance, increased uniformity, and improved heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

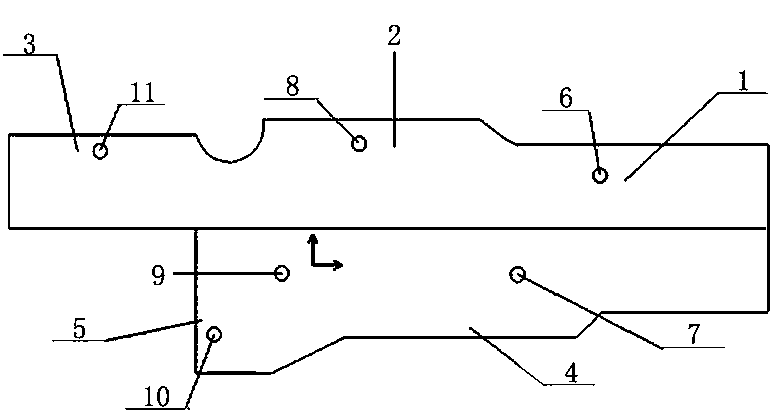

[0025] This embodiment provides a heating process for strip steel resistant to sulfuric acid leakage corrosion. The heating furnace used in the heating process includes a preheating section 1, an upper heating section 2, a soaking section 3, a lower heating end firing section 4 and a lower heating section. Side burning section 5, the structure is as follows figure 1 As shown, there are 6 temperature detection points on the heating furnace, including: temperature control point 6 in the preheating section, temperature detection point 7 in the lower heating side, temperature detection point 8 in the upper heating section, and temperature detection point I9 in the lower heating end , The temperature detection point II10 of the lower heating end and the temperature detection point 11 of the soaking section.

[0026] Preheating section temperature detection point 6 set temperature: 520~800℃; lower heating side burning temperature detection point 7 set temperature: 1000~1180℃; upper ...

Embodiment 2

[0031] This embodiment provides a heating process for strip steel resistant to sulfuric acid leakage corrosion. The heating furnace used in the heating process includes a preheating section 1, an upper heating section 2, a soaking section 3, a lower heating end firing section 4 and a lower heating section. Side burning section 5, the structure is as follows figure 1 As shown, there are 6 temperature detection points on the heating furnace, including: temperature control point 6 in the preheating section, temperature detection point 7 in the lower heating side, temperature detection point 8 in the upper heating section, and temperature detection point I9 in the lower heating end , Temperature detection point II10 at the lower heating end and temperature detection point 11 at the soaking section.

[0032] Preheating section temperature detection point 6 set temperature: 520~800℃; lower heating side burning temperature detection point 7 set temperature: 1000~1180℃; upper heating ...

Embodiment 3

[0037]This embodiment provides a heating process for strip steel resistant to sulfuric acid leakage corrosion. The heating furnace used in the heating process includes a preheating section 1, an upper heating section 2, a soaking section 3, a lower heating end firing section 4 and a lower heating section. Side burning section 5, the structure is as follows figure 1 As shown, there are 6 temperature detection points on the heating furnace, including: temperature control point 6 in the preheating section, temperature detection point 7 in the lower heating side, temperature detection point 8 in the upper heating section, and temperature detection point I9 in the lower heating end , The temperature detection point II10 of the lower heating end and the temperature detection point 11 of the soaking section.

[0038] Preheating section temperature detection point 6 set temperature: 520~800℃; lower heating side burning temperature detection point 7 set temperature: 1000~1180℃; upper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com