A Heating Process for Sulfuric Acid Leak Corrosion Resistant Steel Strip

A heating process and sulfuric acid-resistant technology, applied in the field of steel rolling, can solve problems such as corrosion of high-alloy steel, and achieve the effects of uniform billet performance, increased uniformity, and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

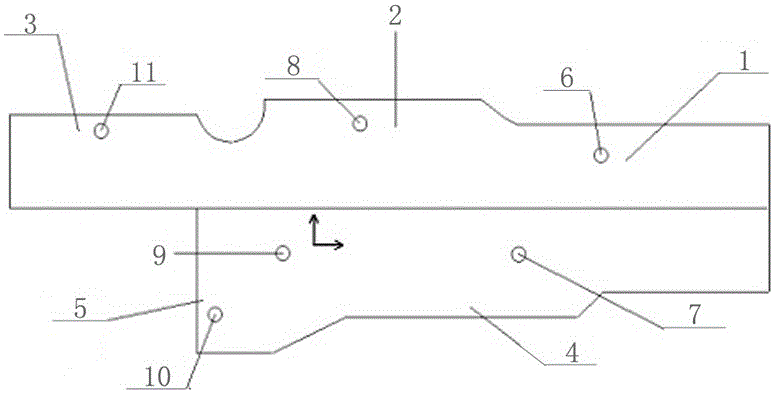

[0025] This embodiment provides a heating process for strip steel resistant to sulfuric acid leakage corrosion. The heating furnace used in the heating process includes a preheating section 1, an upper heating section 2, a soaking section 3, a lower heating end firing section 4 and a lower heating section. Side burning section 5, the structure is as follows figure 1 As shown, there are 6 temperature detection points on the heating furnace, including: temperature control point 6 of the preheating section, temperature detection point 7 of the lower heating side firing section, temperature detection point 8 of the upper heating section, and temperature detection point of the lower heating end firing section Point I9, temperature detection point II10 of the burning section at the lower heating end, and temperature detection point 11 of the soaking section.

[0026] Preheating section temperature temperature control point 6 set temperature: 520~800℃; lower heating side burning sect...

Embodiment 2

[0031] This embodiment provides a heating process for strip steel resistant to sulfuric acid leakage corrosion. The heating furnace used in the heating process includes a preheating section 1, an upper heating section 2, a soaking section 3, a lower heating end firing section 4 and a lower heating section. Side burning section 5, the structure is as follows figure 1 As shown, there are 6 temperature detection points on the heating furnace, including: 6 temperature control points in the preheating section, 7 temperature detection points in the lower heating side firing point, 8 temperature detection points in the upper heating section, and 8 temperature detection points in the lower heating end firing section Ⅰ9. Temperature detection point Ⅱ10 of the firing section at the lower heating end and temperature detection point 11 of the soaking section.

[0032] Preheating section temperature temperature control point 6 set temperature: 520~800℃; lower heating side burning section t...

Embodiment 3

[0037] This embodiment provides a heating process for strip steel resistant to sulfuric acid leakage corrosion. The heating furnace used in the heating process includes a preheating section 1, an upper heating section 2, a soaking section 3, a lower heating end firing section 4 and a lower heating section. Side burning section 5, the structure is as follows figure 1 As shown, there are 6 temperature detection points on the heating furnace, including: 6 temperature control points in the preheating section, 7 temperature detection points in the lower heating side firing point, 8 temperature detection points in the upper heating section, and 8 temperature detection points in the lower heating end firing section Ⅰ9. Temperature detection point Ⅱ10 of the firing section at the lower heating end and temperature detection point 11 of the soaking section.

[0038] Preheating section temperature temperature control point 6 set temperature: 520~800℃; lower heating side burning section t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com