Tobacco sheet stem powder raw material pretreatment mixing and stirring device

A technology for mixing and stirring tobacco sheets, which is applied in the directions of mixers, mixers, and mixer accessories with a rotating stirring device, and achieves the effects of uniformity, convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

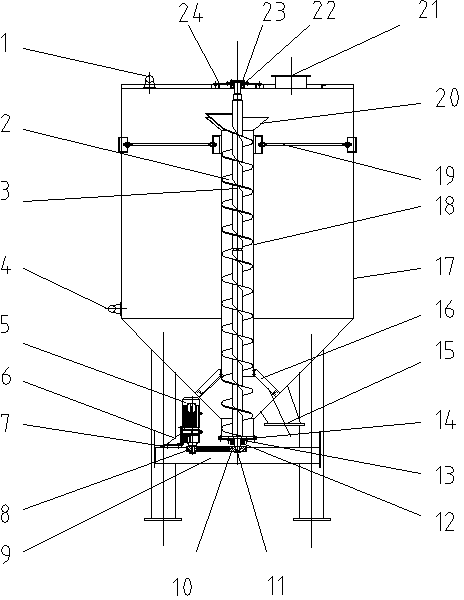

[0015] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention includes a tank body 17, a vertical mixing screw arranged in the tank body 17, a gear motor 5 outside the tank body 17, upper and lower material level detectors 1, 4 and a frame 9 on the tank body 17, The reduction motor 5 fixed on the frame 9 drives the main shaft 3 in the vertical mixing and stirring screw.

[0016] The upper part of the raw material pretreatment mixing tank 17 is welded with a feed inlet 21 and a bearing mounting plate 24, and the lower part is welded with a discharge port 15 and a frame 9, and the upper part of the main shaft 3 of the vertical mixing screw is equipped with an upper bearing Seat 22, upper bearing cover 23 is assembled on the upper bearing seat 22, upper bearing seat 22 is fixed on the bearing seat mounting plate 24, and the spiral stirring blade 2 is welded on the main shaft 3 of the vertical m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com