Micro array type colloid propeller

A technology of micro-array and thruster, which is applied in the direction of thrust reverser, machine/engine, mechanical equipment, etc., can solve the problems such as difficult injection control, and achieve the effect of avoiding influence and interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

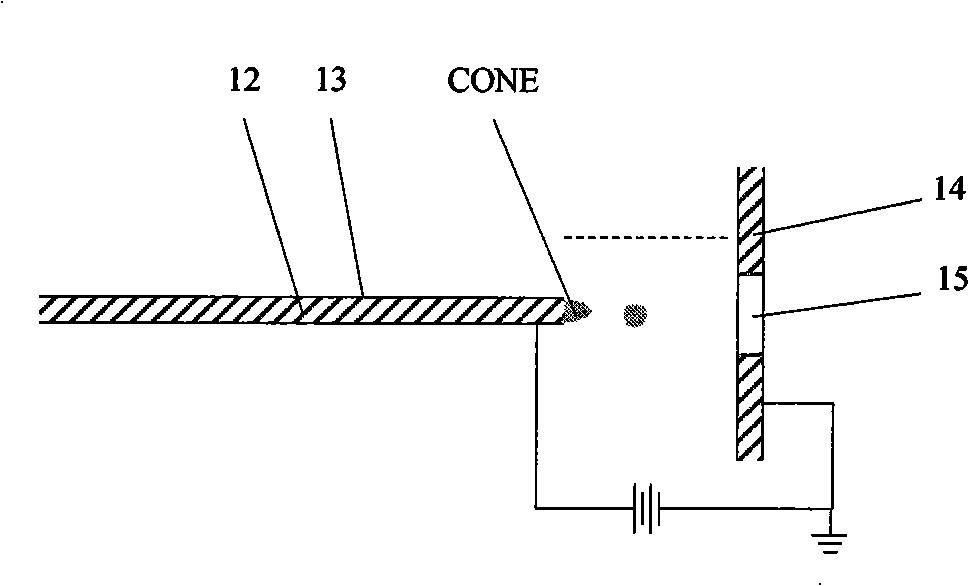

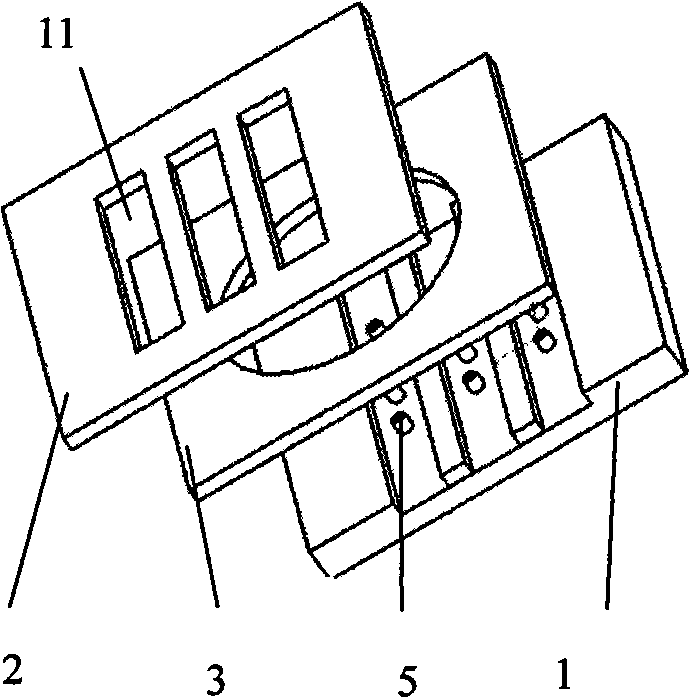

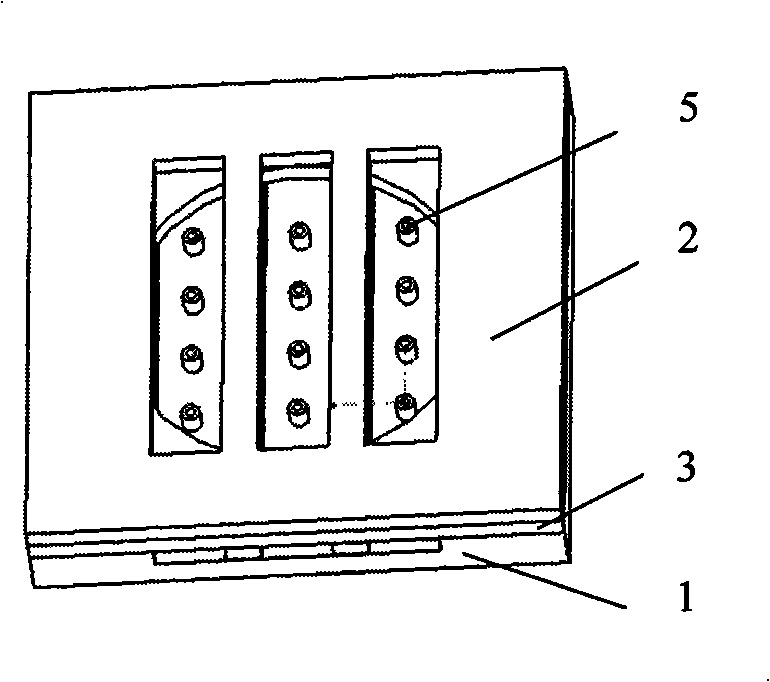

[0022] The micro-array colloid thruster includes the ejector 1 and the extractor 2 made by processing the high-resistance single crystal silicon substrate by ICP etching process, and the ejector 1 and the extractor 2 are placed between the ejector 1 and the extractor 2 and bonded to the two poles. The glass support frame 3 (i.e. the intermediate pole), the high-resistance monocrystalline silicon substrate 4 of the jet electrode 1 is etched with several tubular nozzles 5, and the side of the jet pole 1 etched with the tubular nozzles 5 faces the extraction pole 2, and the tubular nozzles The infusion channel 6 of 5 vertically runs through the high-resistance monocrystalline silicon substrate 4, the tubular nozzles 5 on the jet electrode 1 are arranged in columns, and the high-resistance monocrystalline silicon substrate 4 of the jet electrode 1 is etched with a number of strips parallel to each other. groove 7, and only one row of tubular nozzles 5 is arranged in the strip-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com