Heat treatment method after local welding of quenched and tempered material super-large container

A post-heat treatment, ultra-large technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of large temperature difference in the weld area, affect the mechanical properties of the steel plate, and the temperature is easy to exceed 620 ° C, so as to improve temperature uniformity , reduce the axial temperature gradient, and satisfy the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

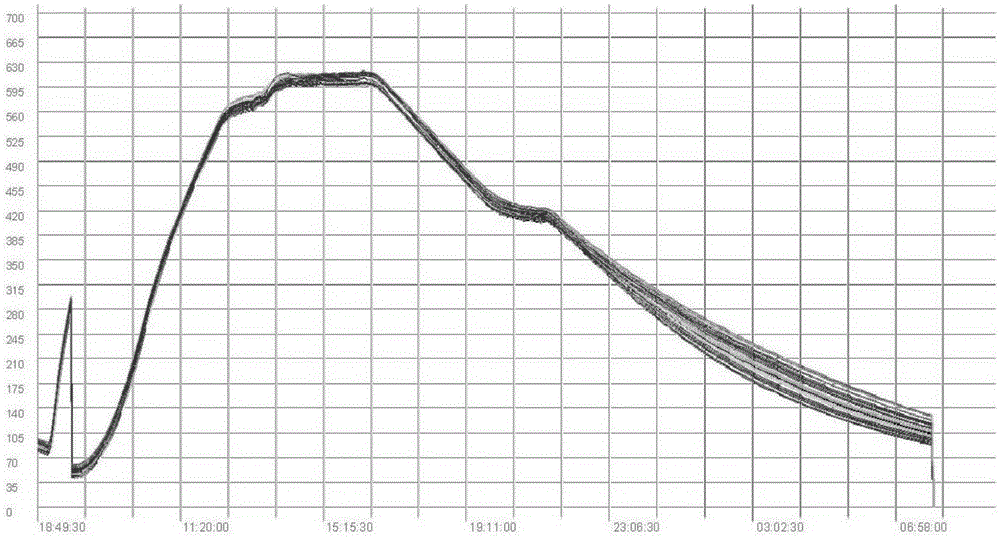

Image

Examples

Embodiment 1

[0029] Heat treatment test steel plate: Quenched and tempered steel plate SA738B, the specification is 100000*4000*45 (mm) 1 sheet.

[0030] Insulation material: aluminum silicate insulation cotton, thickness 180mm, specification 610*4000(mm).

[0031] Crawler heater: specification 600*400(mm), single chip power 10KW.

[0032] Temperature control box: 2 intelligent temperature control boxes, rated power 480KW, 12 temperature control points, temperature control accuracy ±2°C.

[0033] Thermocouple: simple K-type thermocouple, length 2 meters, temperature range 0~800℃, accuracy class I.

[0034] Paperless recorder: 3 sets.

[0035] Energy storage welding machine: 1 set.

[0036] Perform post-weld heat treatment on the longitudinal 4000mm long weld seam, the operation steps are as follows:

[0037] (1) Fix the crawler heater on the wire mesh.

[0038] (2) Fix the thin steel sheet at the position with the highest temperature of the heating sheet, and spot-weld the temperature...

Embodiment 2

[0050] Heat treatment test steel plate: Quenched and tempered steel plate SA738B, the specification is 100000*4000*45 (mm) 1 piece.

[0051] Insulation material: aluminum silicate insulation cotton, thickness 180mm, specification 610*4000(mm).

[0052] Crawler heater: specification 600*400(mm), single chip power 10KW.

[0053] Temperature control box: 2 intelligent temperature control boxes, rated power 480KW, 12 temperature control points, temperature control accuracy ±2°C.

[0054] Thermocouple: simple K-type thermocouple, length 2 meters, temperature range 0~800℃, accuracy class I.

[0055] Paperless recorder: 3 sets.

[0056] Energy storage welding machine: 1 set.

[0057] Perform post-weld heat treatment on the longitudinal 4200mm long weld seam, the operation steps are as follows:

[0058] (1) Fix the crawler heater on the wire mesh.

[0059] (2) Fix the thin steel sheet at the position with the highest temperature of the heating sheet, and spot-weld the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com