Composite material comprising silicon matrix and method of producing the same

a technology of composite materials and silicon matrices, which is applied in the direction of liquid/solution decomposition chemical coating, instruments, record information storage, etc., can solve the problems of increasing production costs, requiring complex production steps, and limited reduction of equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

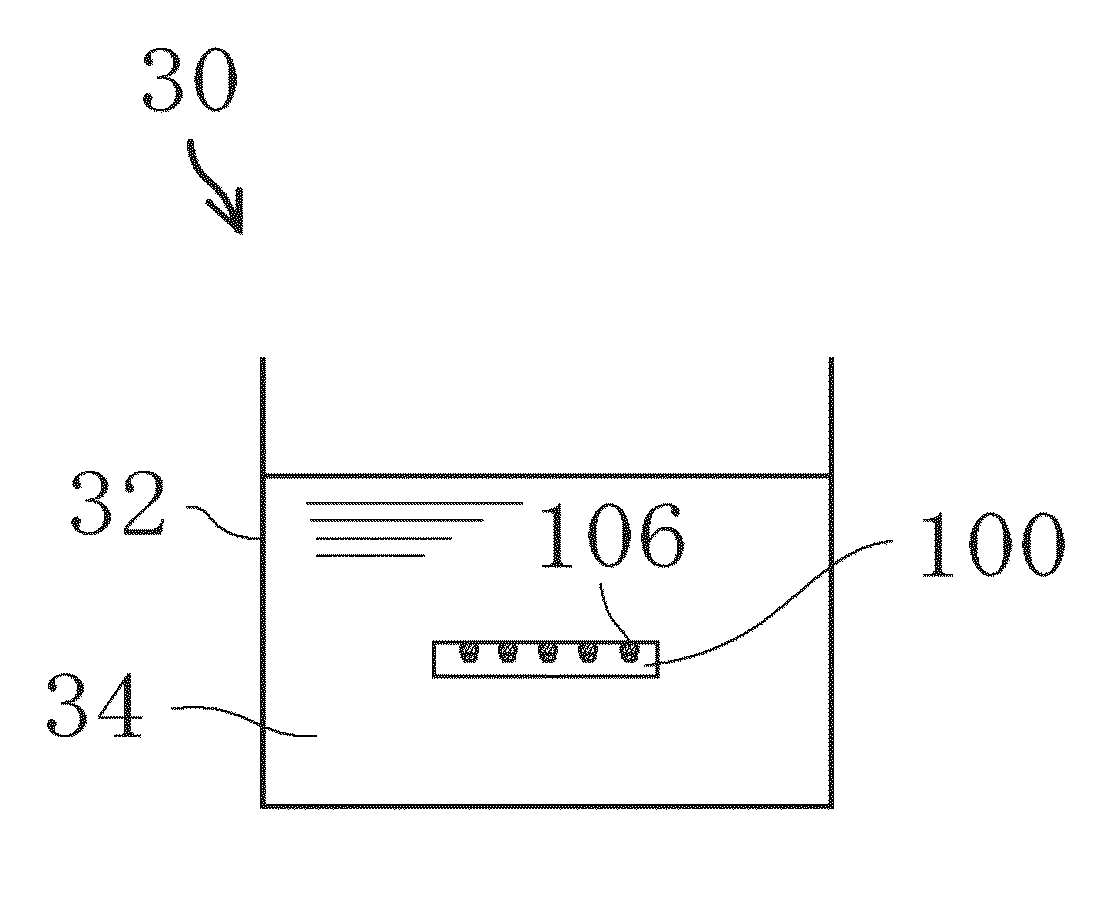

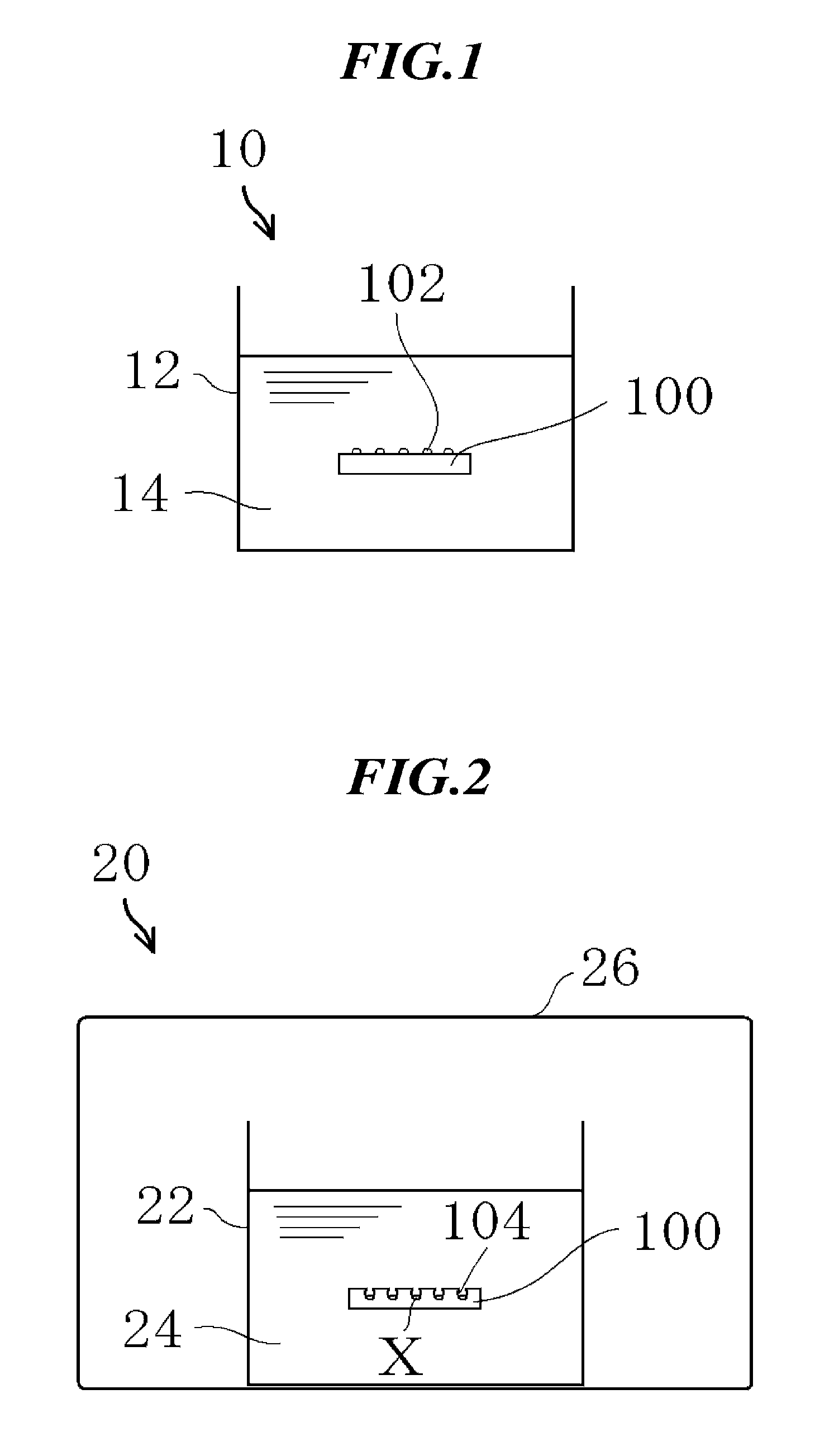

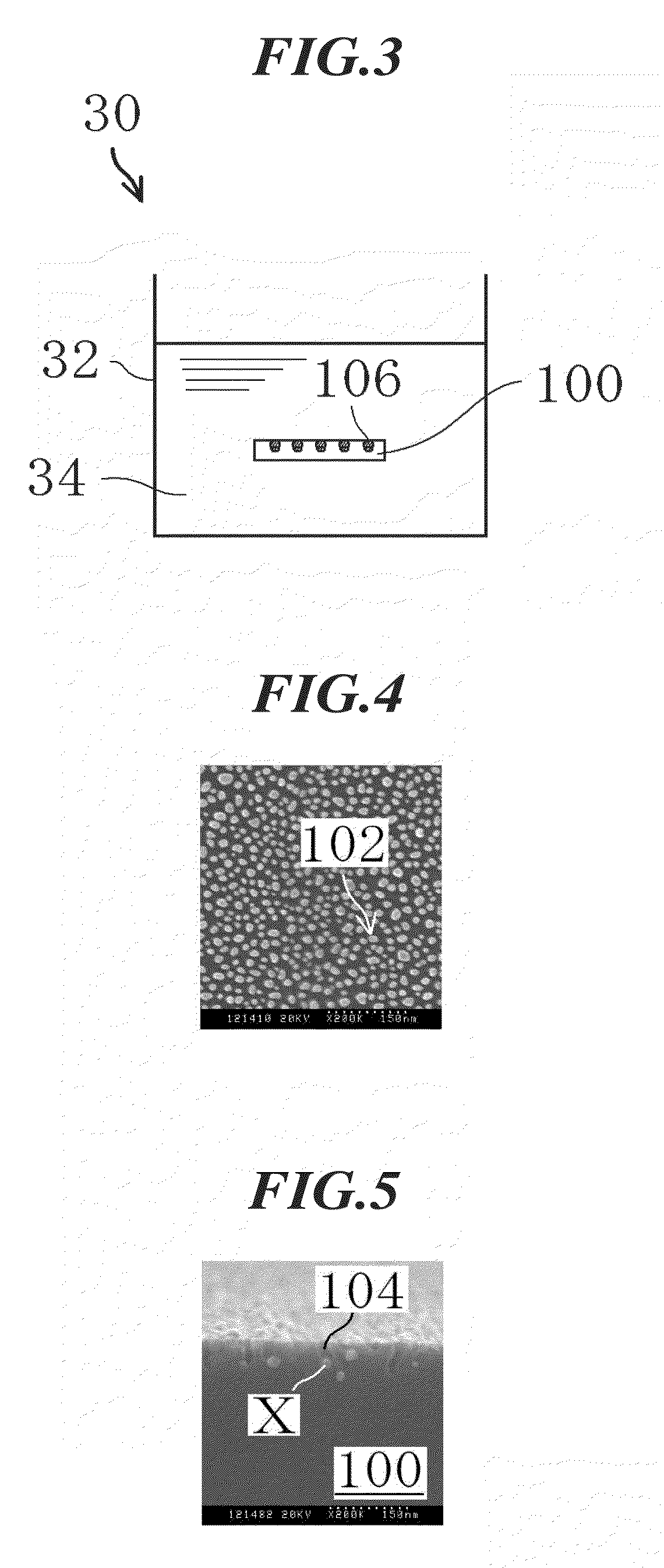

[0048]Described in the present embodiment are a composite material comprising a silicon matrix and a method of producing the same. FIG. 1 is a diagram illustrating a dispersion / allocation device 10 for dispersing and allocating first metal particles on a surface of a silicon substrate according to the present embodiment. FIG. 2 is a diagram illustrating a non-penetrating pore forming device 20 for forming non-penetrating pores in the surface of the silicon substrate. FIG. 3 is a diagram illustrating a filling device 30 for filling a second metal in the non-penetrating pores. The present embodiment adopts silver (Ag) as the first metal and cobalt (Co) as a second metal.

[0049]As shown in FIG. 1, in the present embodiment, a silicon substrate 100 is initially immersed for 30 seconds in an aqueous solution (hereinafter, also referred to as a first solution) 14 that is contained in a reservoir 12 and is preliminarily conditioned to 5° C. This aqueous solution 14 includes silver nitrate (...

second embodiment

[0055]Described in the present embodiment are another composite material comprising a silicon matrix and a method of producing the same. The method of producing the composite material comprising a silicon matrix according to the present embodiment is same as that of the first embodiment except for some conditions. Therefore, the description redundant with that of the first embodiment may not be repeatedly provided.

[0056]In the present embodiment, first metal particles of gold (Au) were dispersed and allocated on the surface of a silicon substrate with use of a dispersion / allocation device 10 configured as shown in FIG. 1. More specifically, the present embodiment adopts as a first solution an aqueous solution that is preliminarily conditioned to 5° C. and includes tetrachloroauric acid (HAuCl4) of a molarity equal to 1 mmol / L (millimole / liter) and hydrofluoric acid (HF) of a molarity equal to 150 mmol / L. Observed as a result was that gold (Au) fine particles 202 of diameters from 4 ...

third embodiment

[0060]Described in the present embodiment are a different composite material comprising a silicon matrix and a method of producing the same. Since the method of producing the composite material comprising a silicon matrix according to the present embodiment is same as that of the first embodiment except for some conditions. Therefore, the description redundant with that of the first embodiment may not be repeatedly provided.

[0061]In the present embodiment, first metal particles of silver (Ag) were dispersed and allocated on the surface of a silicon substrate with use of a dispersion / allocation device 10 configured as shown in FIG. 1. More specifically, the present embodiment adopts as a first solution an aqueous solution that is preliminarily conditioned to 5° C. and includes silver nitrate (AgNO3) of a molarity equal to 1 mmol / L (millimole / liter) and hydrofluoric acid (HF) of a molarity equal to 150 mmol / L.

[0062]Subsequently, the silicon substrate supporting the silver (Ag) fine pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com