Glass roll and method for manufacturing same

A glass roll and glass film technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problem of glass film damage, and achieve the effect of inhibiting damage and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

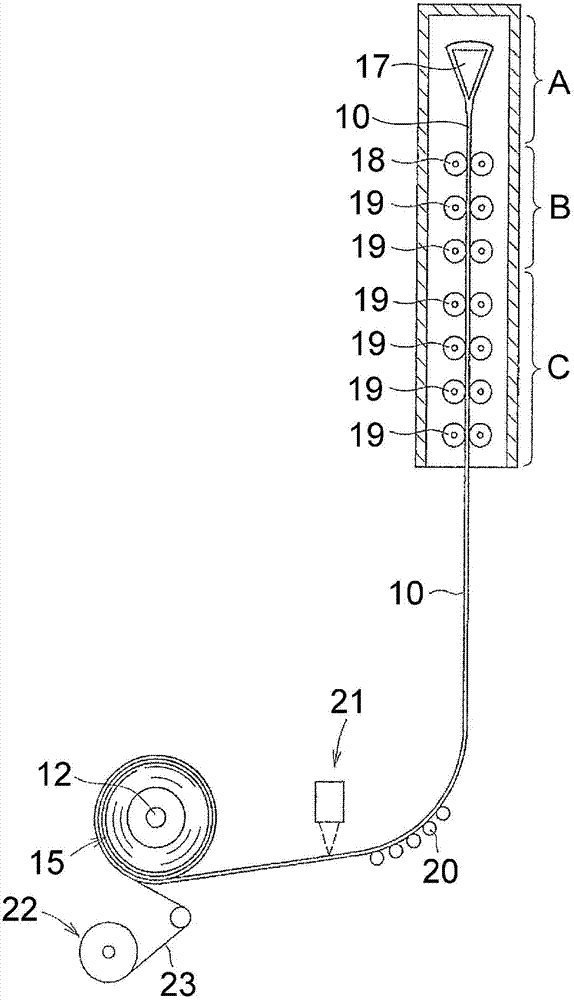

[0034] Hereinafter, preferred embodiment of the glass roll of this invention is demonstrated.

[0035]The glass film used in the present invention has a thickness of 0.5 to 300 μm. A glass film having such a thickness can be obtained by pulling glass downward by a down-draw method to continuously form it into a film. When the thickness of the glass film is less than 0.5 μm, it is easy to break, and when the thickness of the glass film is more than 300 μm, the flexibility is insufficient, and it is difficult to be wound into a roll. The thickness of the glass film is 5 to 200 μm, preferably 5 to 100 μm, more preferably 5 to 50 μm.

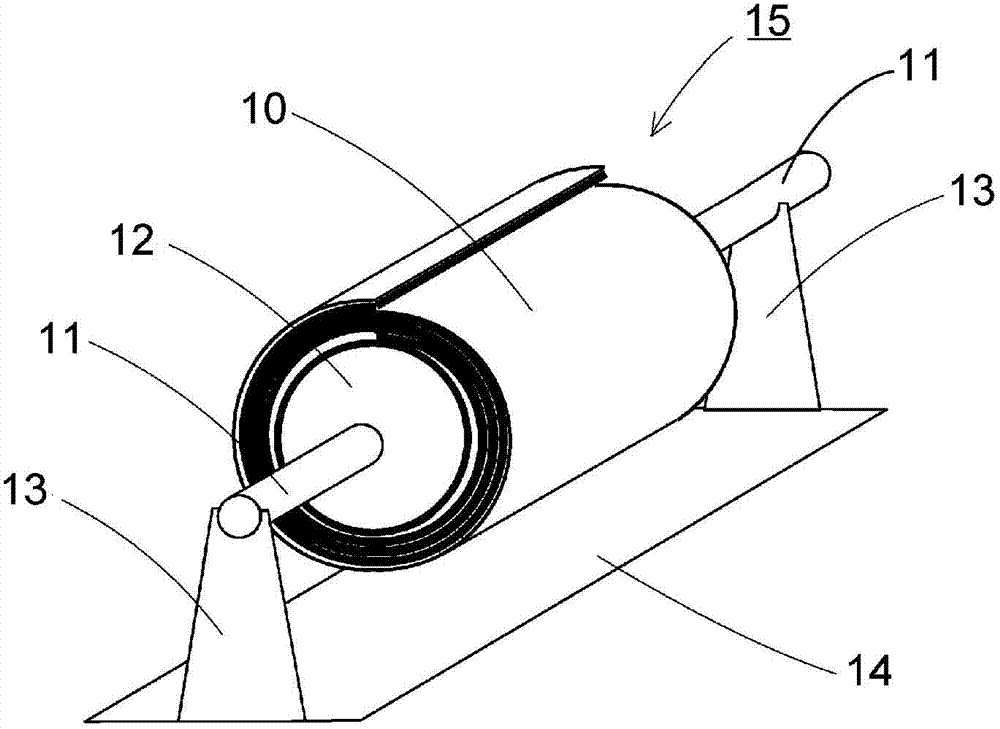

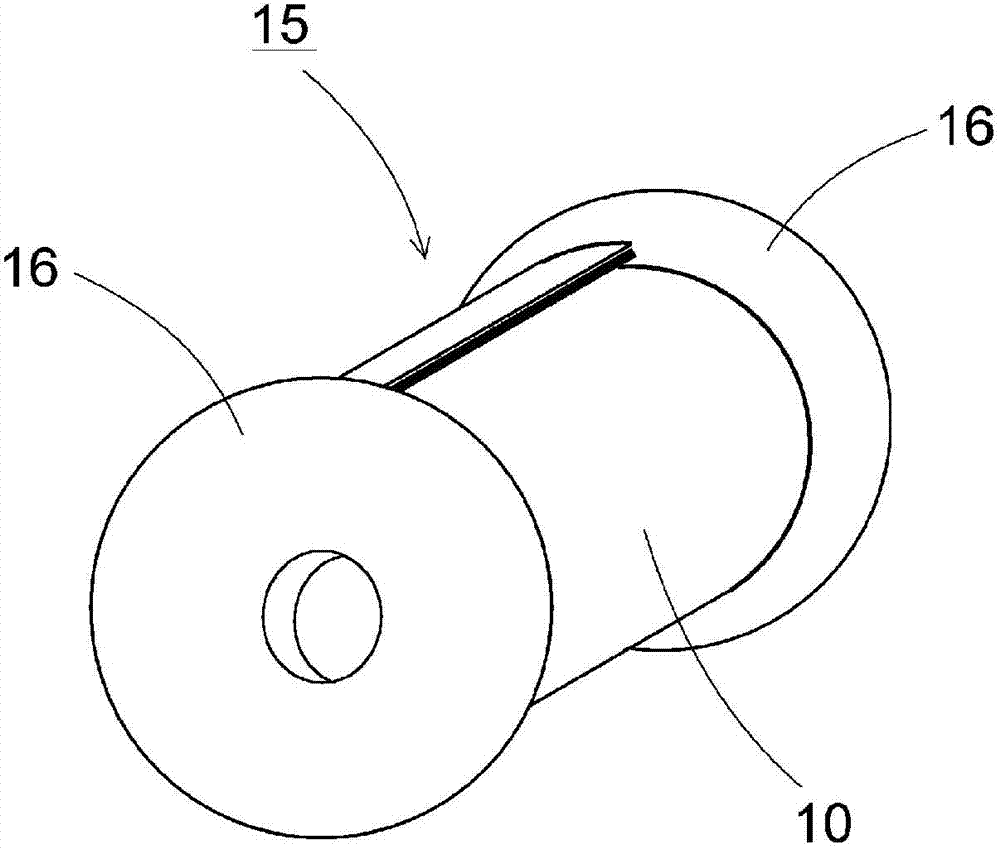

[0036] The density of the glass film is less than 2.45g / cm 3 . Therefore, weight reduction can be achieved, even if a glass film with a length of 50 m or more is wound, a support rod is installed on the central axis of the glass roll, and the outer surface of the glass roll is kept in a state where it is not in contact with the mounting surface. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com