A kind of preparation method of fast charging graphite composite material

A composite material and graphite technology, applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve the problems of insufficient lithium ion intercalation, affecting material rate performance and safety performance, conductivity deviation, etc., to reduce irreversible capacity , Improve fast charging performance and safety performance, and improve the effect of embedding channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

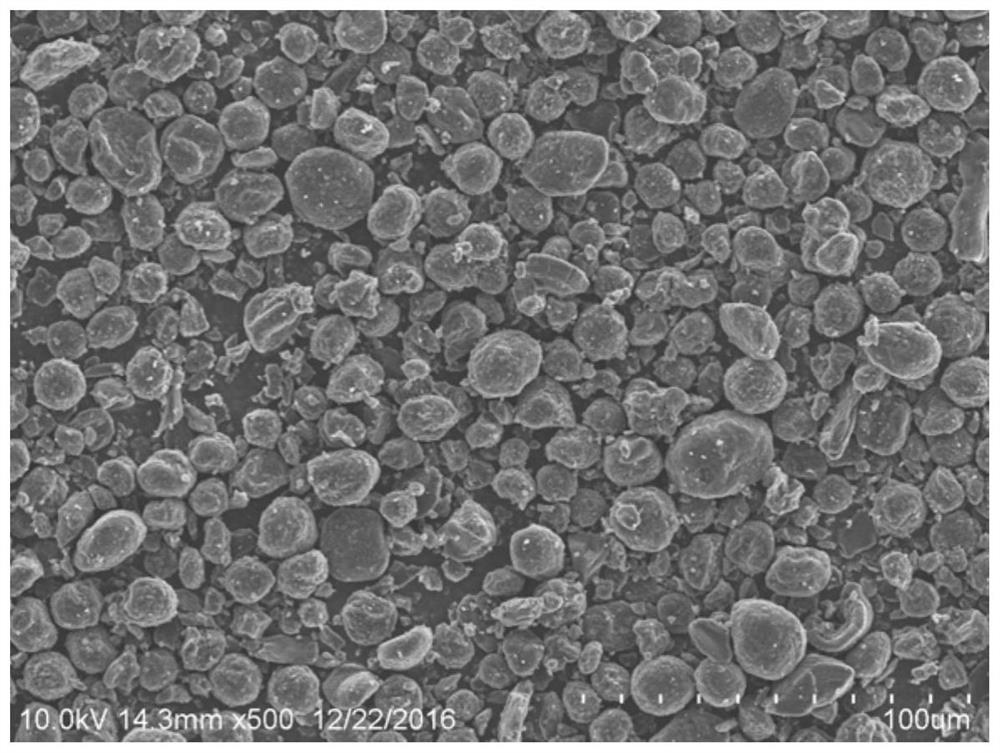

Image

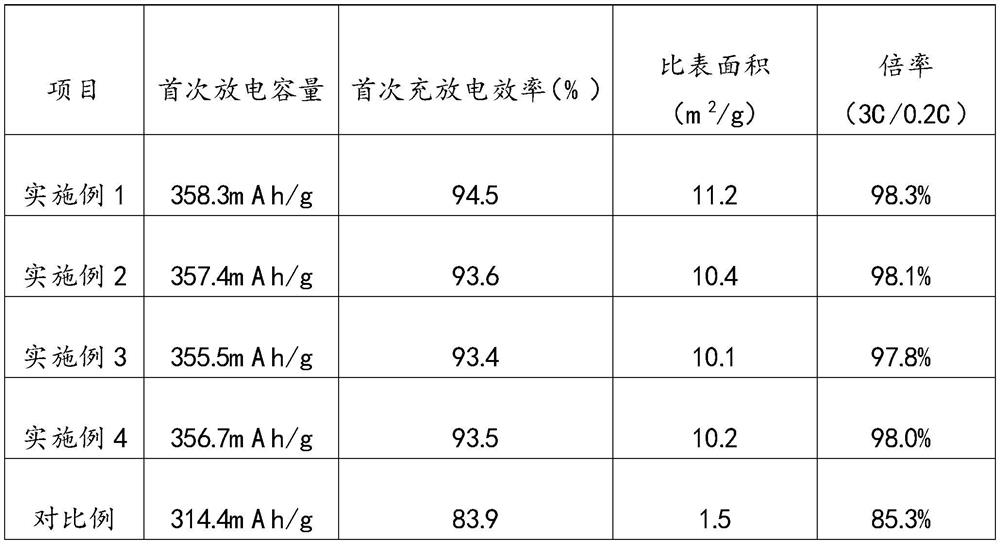

Examples

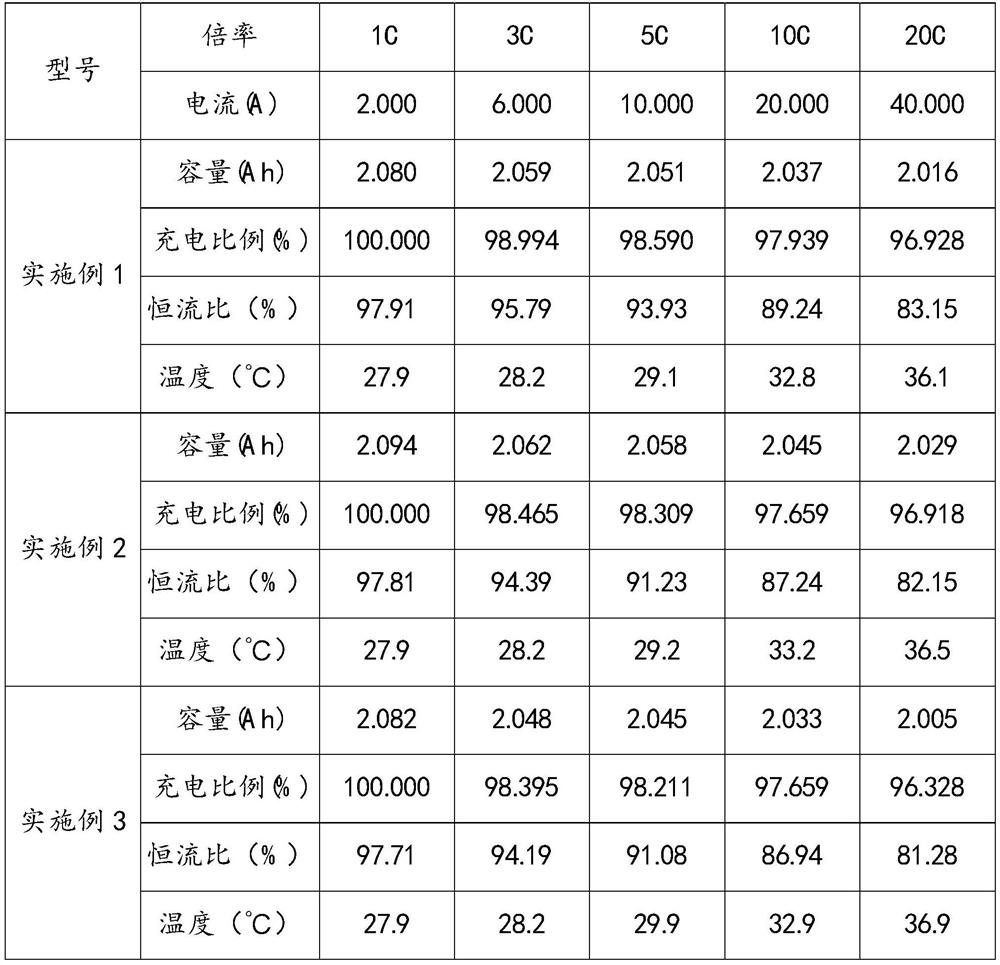

Embodiment 1

[0024] A preparation method for fast-filling graphite composite material, comprising the following steps:

[0025] (1) Add 100g of organic titanium epoxy resin into 500ml of toluene, mix and stir evenly to obtain a mixed solution with a weight concentration of 20%; add graphene to the mixed solution, stir evenly, and then transfer it to a high-pressure reactor for hydrothermal reaction , the heating temperature is 80°C and the pressure is 3Mpa and the reaction is 2h. After the reaction is completed, the filtrate is removed by filtration. At a temperature of 50°C and a vacuum of 50pa, the filter residue is dried for 48h, and then transferred to a tube furnace. Carbonization at 550°C for 7 hours in an argon inert gas environment, resulting in a porous composite hard carbon matrix;

[0026] (2) 1g of lithium carbonate is added into deionized water to configure a lithium carbonate aqueous solution with a weight concentration of 5%, and 10g of porous composite hard carbon matrix is...

Embodiment 2

[0029] A preparation method for fast-filling graphite composite material, comprising the following steps:

[0030] (1) Add 100g of organic titanium epoxy resin into 1000g of xylene, mix and stir evenly to obtain a mixed solution with a weight concentration of 10%; add 3g graphene to the mixed solution, stir evenly, transfer to the autoclave for hydrothermal Reaction, react at a heating temperature of 60°C and a pressure of 5Mpa for 1h. After the reaction is complete, filter and remove the filtrate. At a temperature of 30°C and a vacuum of 100pa, dry the filter residue for 72h, then transfer it to a tube furnace and In an inert gas argon environment, carbonize the filter residue at a high temperature of 500°C for 8 hours to form a porous composite hard carbon matrix;

[0031] (2) 3g of lithium carbonate is added into deionized water to configure a weight concentration of 8% inorganic lithium salt solution, and 20g of porous composite hard carbon matrix is added to the inorgan...

Embodiment 3

[0034] A preparation method for fast-filling graphite composite material, comprising the following steps:

[0035] (1) Add 100g organic titanium epoxy resin into 2000g acetone, mix and stir evenly to obtain a mixed solution with a weight concentration of 5%; add 1g graphene to the mixed solution, stir evenly, and transfer it to a high-pressure reactor for hydrothermal reaction , react at a heating temperature of 90°C and a pressure of 3Mpa for 2h. After the reaction is complete, filter and remove the filtrate. At a temperature of 80°C and a vacuum of 10pa, dry the filter residue for 12h, then transfer it to a tube furnace and In an inert gas argon environment, carbonize the filter residue at a high temperature of 550°C for 7 hours to form a porous composite hard carbon matrix;

[0036] (2) 1g of lithium hydroxide is added into deionized water to configure an inorganic lithium salt solution with a weight concentration of 7%, and 10g of porous composite hard carbon matrix is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com