Method for synthesizing methyl acrylate

A technology of methyl acrylate and a synthesis method, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as low yield, achieve simple preparation process, good catalytic activity and selectivity, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

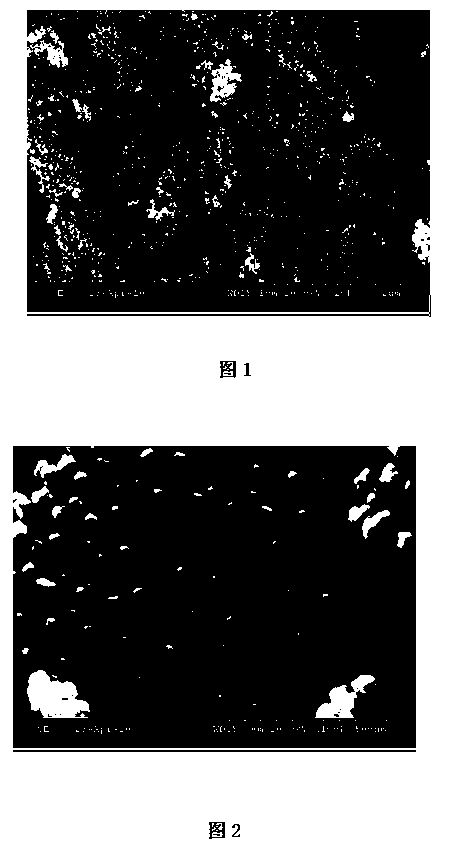

Image

Examples

Embodiment 1

[0018] Add tetraethyl orthosilicate and ethanol into a 250ml three-neck flask at a ratio of 1.2:1 by volume, add 30ml of water, take a water bath to 50°C, and use HNO 3 Adjust pH=4, add a small amount of cetyl dimethyl ammonium bromide as a surfactant, stir for 3 hours to prepare SiO 2 Sol. Another 20gSb 2 o 3 Mix it with 2Oml of distilled water in a 50ml three-neck flask, heat to 80°C and stir to stabilize, then add 3ml of triethanolamine, stir for 15min, then heat up to 90°C, then add 3ml of H 2 o 2 (dropwise), continue to stir for 90min until the solution changes from a white suspension to a colorless transparent antimony sol.

[0019] The two sols were thoroughly mixed according to 6:1 (volume ratio), and adjusted to pH=10. The polystyrene template and the mixed solution were assembled by impregnation, ultrasonication, and suction filtration by the in-situ method, and then dried at 70°C for 1 hour, and then programmed to heat up to 600°C for 8 hours under the conditio...

Embodiment 2

[0023] Add tetraethyl orthosilicate and ethanol into a 250ml three-neck flask at a ratio of 1.2:1 by volume, add 30ml of water, take a water bath to 50°C, and use HNO 3 Adjust pH=4, add a small amount of cetyltrimethylammonium bromide as a surfactant, stir for 3 hours to prepare SiO 2 Sol. Another 25gSb 2 o 3 Mix with 20ml in a 50ml three-neck flask, heat to 80°C and stir to stabilize, then add 3ml of triethanolamine, stir for 15min, then heat up to 90°C, then add 3ml of H 2 o 2 (dropwise), continue to stir for 90min until the solution changes from a white suspension to a colorless transparent antimony sol.

[0024] The two sols were thoroughly mixed according to 7:1 (volume ratio), and adjusted to pH=10. The polystyrene template and the mixed solution were assembled by impregnation, ultrasonication, and suction filtration in situ, and then dried at 80°C for 1 hour, extracted with acetone and tetrahydrofuran, and repeated 4 times. The macroporous Sb 2 o 5 / SiO 2 Mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com