Method for preparing meso-microporous pure silicon molecular sieve with high specific surface area based on silica white

A high specific surface area, pure silicon molecular sieve technology, applied in molecular sieve compounds, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., to achieve the effect of large pore volume, controllable specific surface area, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

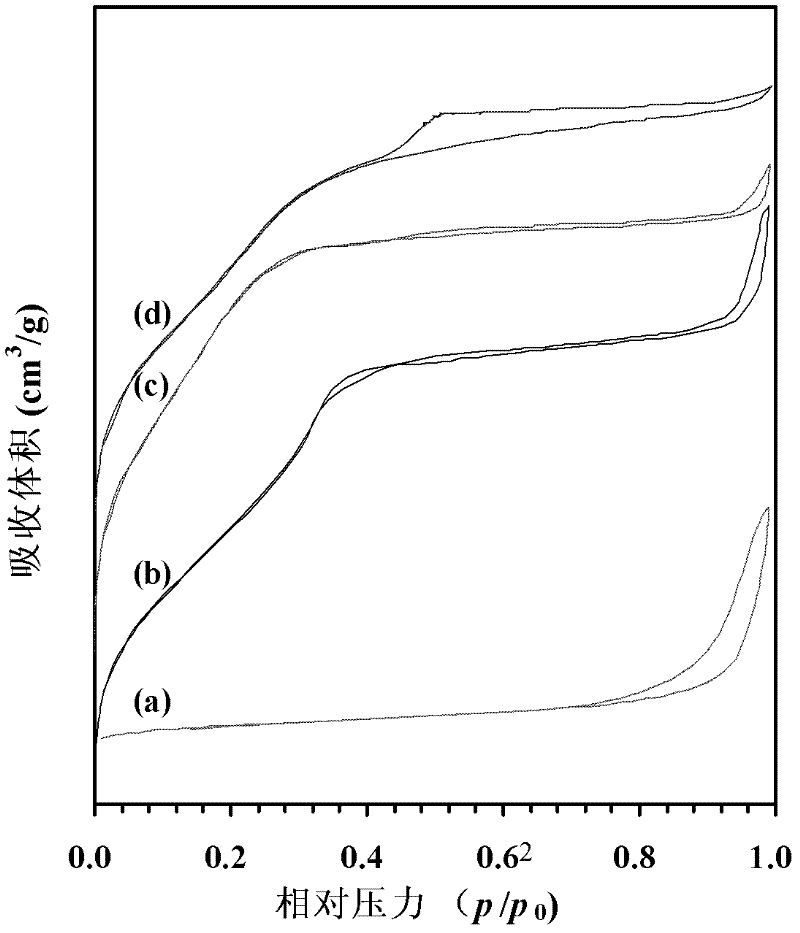

Embodiment 1

[0015] Embodiment 1: Take by weighing 1.067g NaOH, 4.533g cetyltrimethylammonium hydroxide (CTAOH) and 1.23g triblock copolymer (F127), be placed in 150mL beaker, add 80mL deionized water, in After stirring at 50 °C for 1 h, a homogeneous solution was formed. Add 1.5g of white carbon black under strong stirring, continue to stir at room temperature for 1h, transfer the obtained amorphous gel to a 100mL reactor lined with polytetrafluoroethylene, seal it, and conduct hydrothermal treatment at 120°C for 12h, and the hydrothermal treatment is completed Afterwards, the mixture was washed, suction-filtered, and dried at 80°C for 12h, then the obtained white solid powder was placed in a muffle furnace, raised to 550°C at a rate of 1°C / min and kept at this temperature for 4h, and finally A mesoporous silica molecular sieve with a high specific surface area is obtained. The specific surface area is 1090m 2 / g, the pore volume is 0.89cm 3 / g, the mesopore diameter is 3.3nm.

Embodiment 2

[0016] Example 2: Weigh 1.067g NaOH, 4.533g CTAOH and 1.23g F127, place in a 150mL beaker, add 80mL deionized water, and stir at 50°C for 1 hour to form a homogeneous solution. Add 1.5g of white carbon black under strong stirring, continue to stir at room temperature for 1h, transfer the obtained amorphous gel to a 100mL reaction kettle lined with polytetrafluoroethylene and seal it, and hydrothermally treat it at 120°C for 24h, and the hydrothermal treatment ends Afterwards, the mixture was washed, suction-filtered, and dried at 80°C for 12h, then the obtained white solid powder was placed in a muffle furnace, raised to 550°C at a rate of 1°C / min and kept at this temperature for 4h, and finally A mesoporous silica molecular sieve with a high specific surface area is obtained. The specific surface area is 1405m 2 / g, the pore volume is 0.76cm 3 / g, the mesopore diameter is 2.2nm.

Embodiment 3

[0017] Example 3: Weigh 1.067g NaOH, 4.533g CTAOH and 1.23g F127, place in a 150mL beaker, add 80mL deionized water, and stir at 50°C for 1 hour to form a homogeneous solution. Add 1.5g of white carbon black under strong stirring, continue to stir at room temperature for 1h, transfer the obtained amorphous gel to a 100mL reaction kettle lined with polytetrafluoroethylene, seal it, and conduct hydrothermal treatment at 120°C for 48h, and the hydrothermal treatment is completed Afterwards, the mixture was washed, suction-filtered, and dried at 80°C for 12h, then the obtained white solid powder was placed in a muffle furnace, raised to 550°C at a rate of 1°C / min and kept at this temperature for 4h, and finally A mesoporous silica molecular sieve with a high specific surface area is obtained. The specific surface area is 1186m 2 / g, the pore volume is 0.74cm 3 / g, the mesopore diameter is 2.5nm.

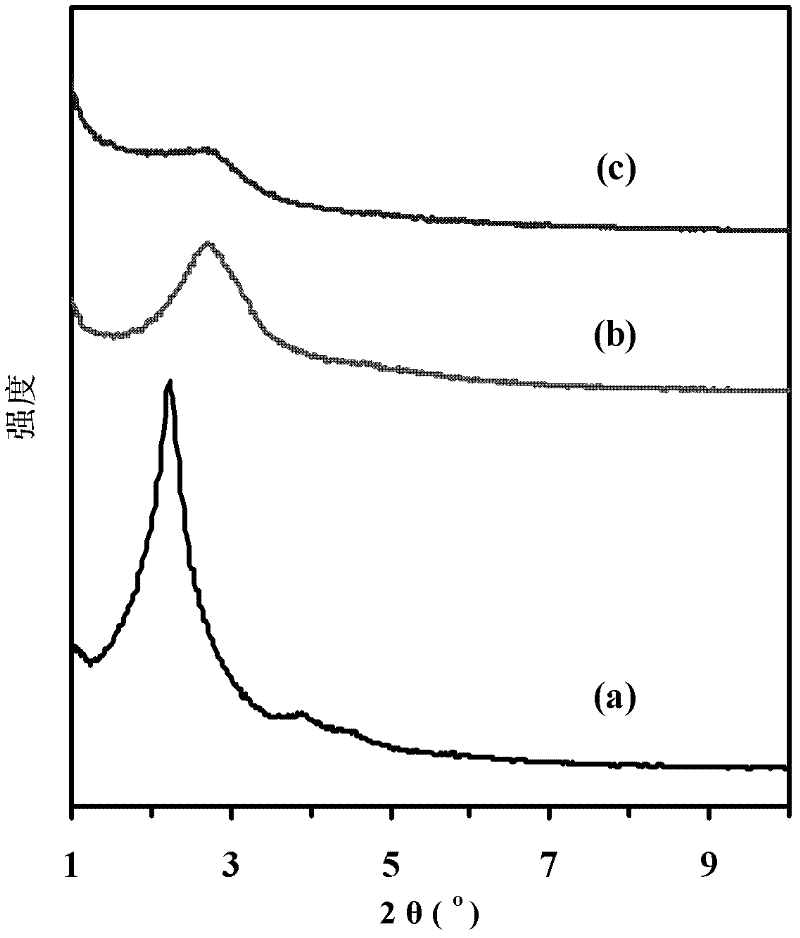

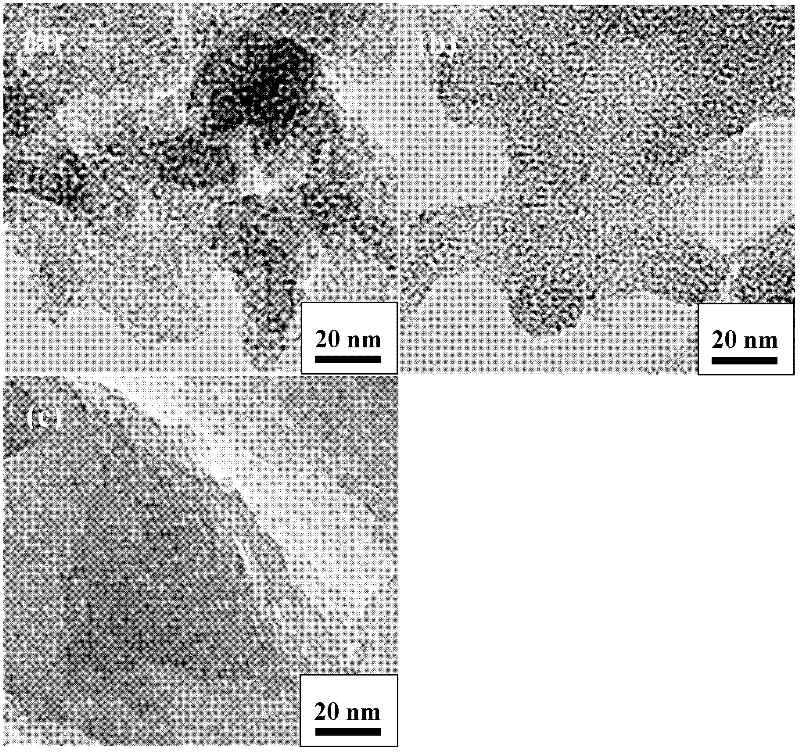

[0018] The XRD spectrogram of the mesoporous silica molecular sieve sample obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com