Renewable two-dimensional compound film and production method and application thereof

A composite film and reaction technology, applied in the direction of material electrochemical variables, etc., can solve problems such as difficulty in regulating the area of two-dimensional nano-gold single-layer film, affecting the health of operators, environmental pollution, etc., and achieve good self-supporting performance and renewable performance, facilitate large-scale implementation, simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

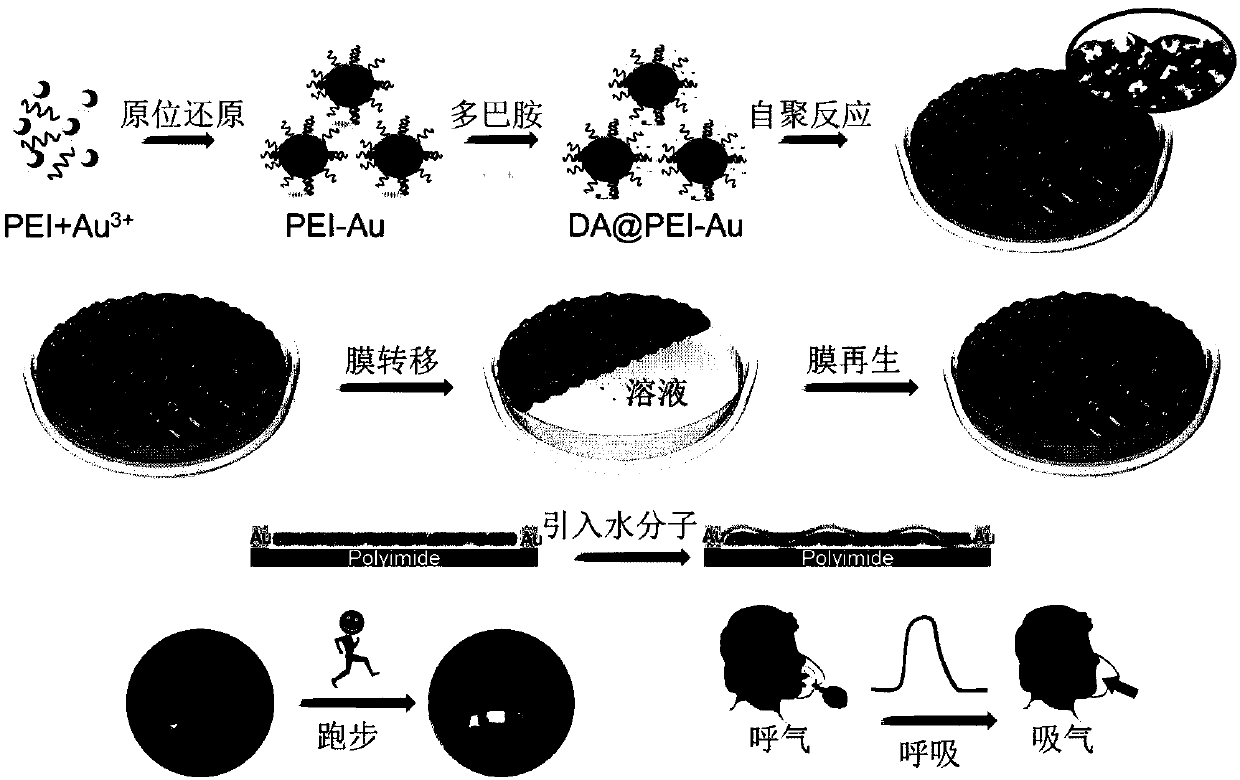

[0032] An aspect of the embodiments of the present invention provides a method for preparing a renewable two-dimensional composite membrane, which includes:

[0033] A first ligand, a second ligand and a gold source are provided, wherein the first ligand is reductive and has a reducing functional group capable of combining with the gold source, and the second ligand can be combined with the gold source Reducing functional groups undergo chemical cross-linking reactions and can undergo self-polymerization reactions;

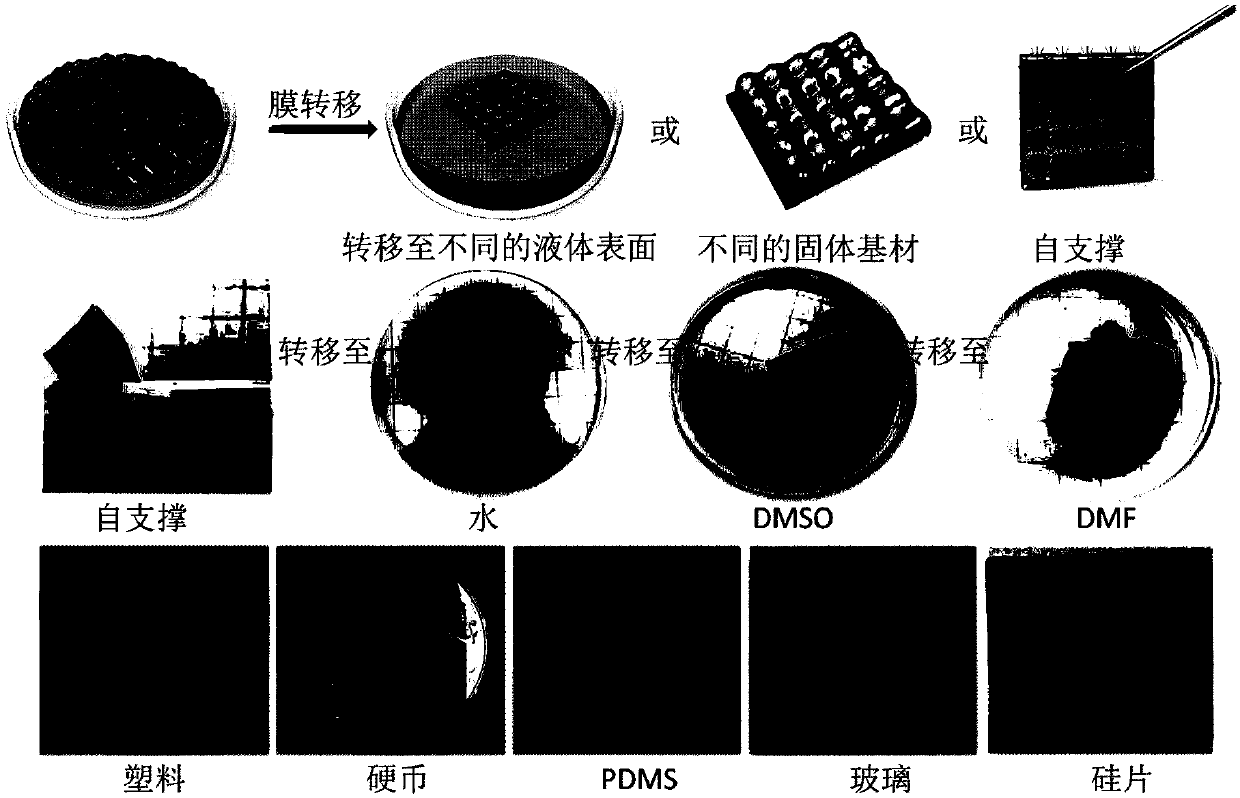

[0034] Using the first ligand as a reducing agent and a stabilizer to reduce the gold source in situ to form gold nanoparticles with a surface rich in reducing functional groups; and, allowing the second ligand to self-polymerize at the water / air interface reaction, and the chemical cross-linking reaction between the second ligand and the reducing functional group on the surface of the gold nanoparticle at the water / air interface, thereby inducing the self-assembl...

Embodiment 1

[0084] Example 1: Nano-gold-dopamine renewable two-dimensional composite film humidity sensor, its preparation method and application

[0085] (1) Preparation of gold nanoparticles in situ reduced by PEI: PEI functionalized gold nanoparticles (PEI / AuNPs) were obtained by in situ reduction of chloroauric acid with amino groups in PEI. First, PEI (69.4 mg) was dissolved in deionized water (10 mL), and 153 μL (0.1M) HAuCl 4 As an aqueous solution, heat in an oil bath at 65°C and stir rapidly for 2h. The synthesized wine-red PEI / AuNPs were stored in a refrigerator at 4°C until use;

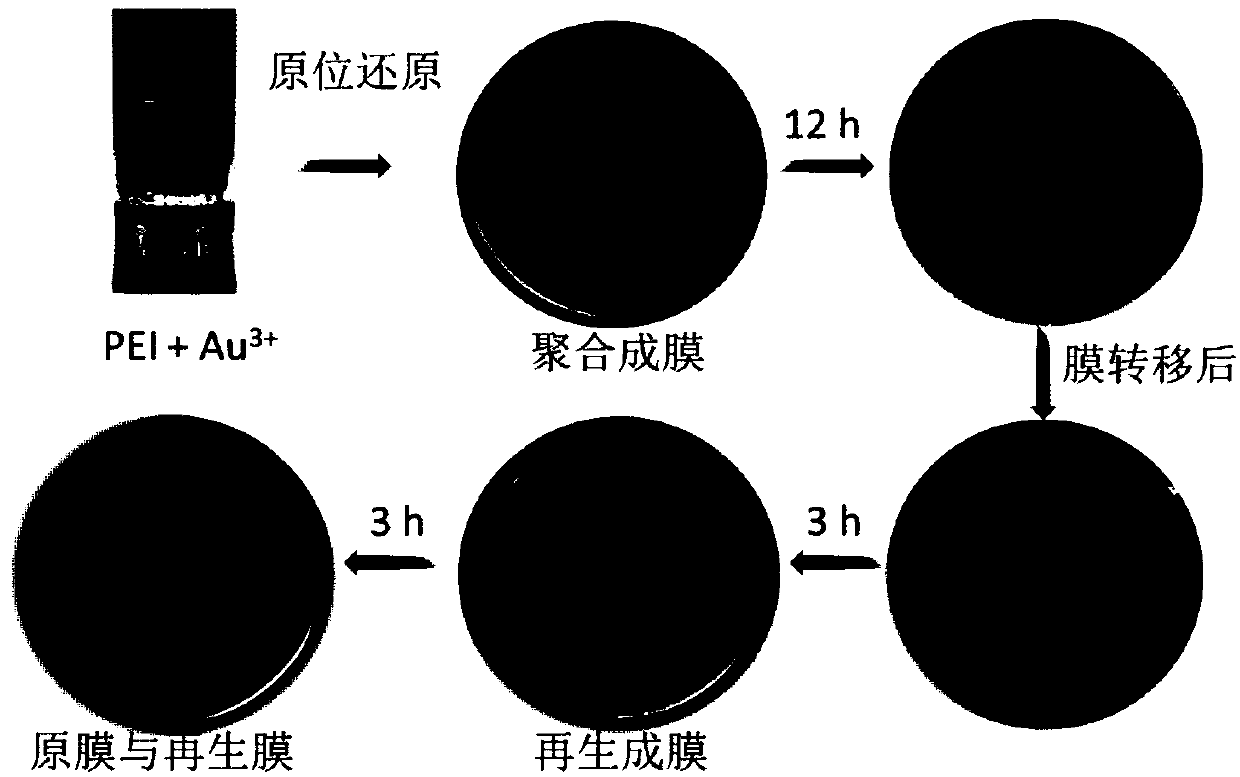

[0086] (2) Preparation of nano-gold-dopamine composite two-dimensional membrane: take a petri dish with a diameter of 75 mm, add 15 mL of deionized water, dissolve 40 mg of dopamine hydrochloride in deionized water, add 3 mL of the PEI / AuNPs original solution synthesized above and 2 mL of Tris buffer (tris, 100 mmol / L, pH=8.5). After standing for more than 12 hours, a thin film can be formed at the...

Embodiment 2

[0088] Example 2: Nano-gold-dopamine renewable two-dimensional composite film humidity sensor, its preparation method and application

[0089] This embodiment is basically the same as Embodiment 1, the difference is:

[0090] In step (1), polyacrylamide is used to replace PEI in Example 1, and HAuCl is reduced in situ 4 The temperature of the aqueous solution was 60°C.

[0091] Step (2) The self-polymerization reaction of dopamine and the chemical cross-linking reaction of dopamine and the reducing functional group on the surface of gold particles are all carried out at room temperature, wherein the concentration of gold nanoparticles is 0.1mmol / L, and the concentration of dopamine is 0.1mg / mL , the concentration of tris buffer is 0.1mmol / L.

[0092] Step (3) The construction and performance testing of the humidity sensor are basically the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com