Large-pore-volume silicon dioxide with nanoparticle structure and preparation method thereof

A nanoparticle and silica technology, which is applied in the field of preparation of macroporous silica, can solve the problems of uncontrolled average particle size and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: do seven parallel sample experiments:

[0019] Each preparation weight percent concentration is 6% sodium silicate solution 1000g and the weight percent concentration is 15% sulfuric acid solution 300g; Add dispersant fatty alcohol and ethylene oxide condensate 10g, react, and the reaction time is controlled at After 3 hours, add sulfuric acid to adjust the pH value to 3-4; raise the temperature of the material to 80°C for thermal activation treatment. The primary particle is controlled at 8-10nm, and then washed with water, spray-dried and cut into an average of 5-6 microns by using supersonic airflow. Its product properties are shown in Table 1:

[0020] Table 1

[0021]

Embodiment 2

[0022] Embodiment 2: do seven parallel sample experiments:

[0023] Each prepared 1000g of sodium silicate solution with 12% silicon dioxide content, reacted with 200g of solution with 10% sulfuric acid content and added 40g of polyethylene glycol at the same time, the reaction time was controlled at 5 hours, and then added sulfuric acid pH value For 3-4, heat the material to 100°C for thermal activation. Control the primary particles to 10-15nm, then wash with water, spray dry and use supersonic airflow to cut the dried particles into an average of 5-6 microns. The product properties are shown in Table 2:

[0024] Table 2

[0025]

Embodiment 3

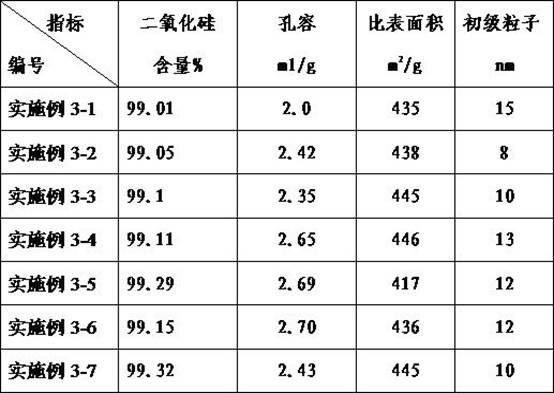

[0026] Embodiment 3: do seven parallel sample experiments:

[0027] Prepare 1000g of sodium silicate solution with a silicon dioxide content of 12% for each, react with 250g of a sulfuric acid solution with a prepared content of 15%, and add 30g of glycerol oleate at the same time. The reaction time is controlled at 2 hours, and the pH is adjusted by adding sulfuric acid. The value is 3-5 warming up to 90°C for thermal activation. Control the primary particles to 10-15nm, wash with water, spray dry and use supersonic airflow to cut the dried particles into an average of 5-6 microns. The product properties are shown in Table 3:

[0028] table 3

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com