Fuel cell

A fuel cell and liquid fuel technology, applied in the direction of fuel cells, fuel cell integration, fuel cell additives, etc., can solve problems such as instability, increase battery characteristics, and difficulty in control, and achieve easy setup, reduced defect rate, and short-circuit defects Eliminate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065]

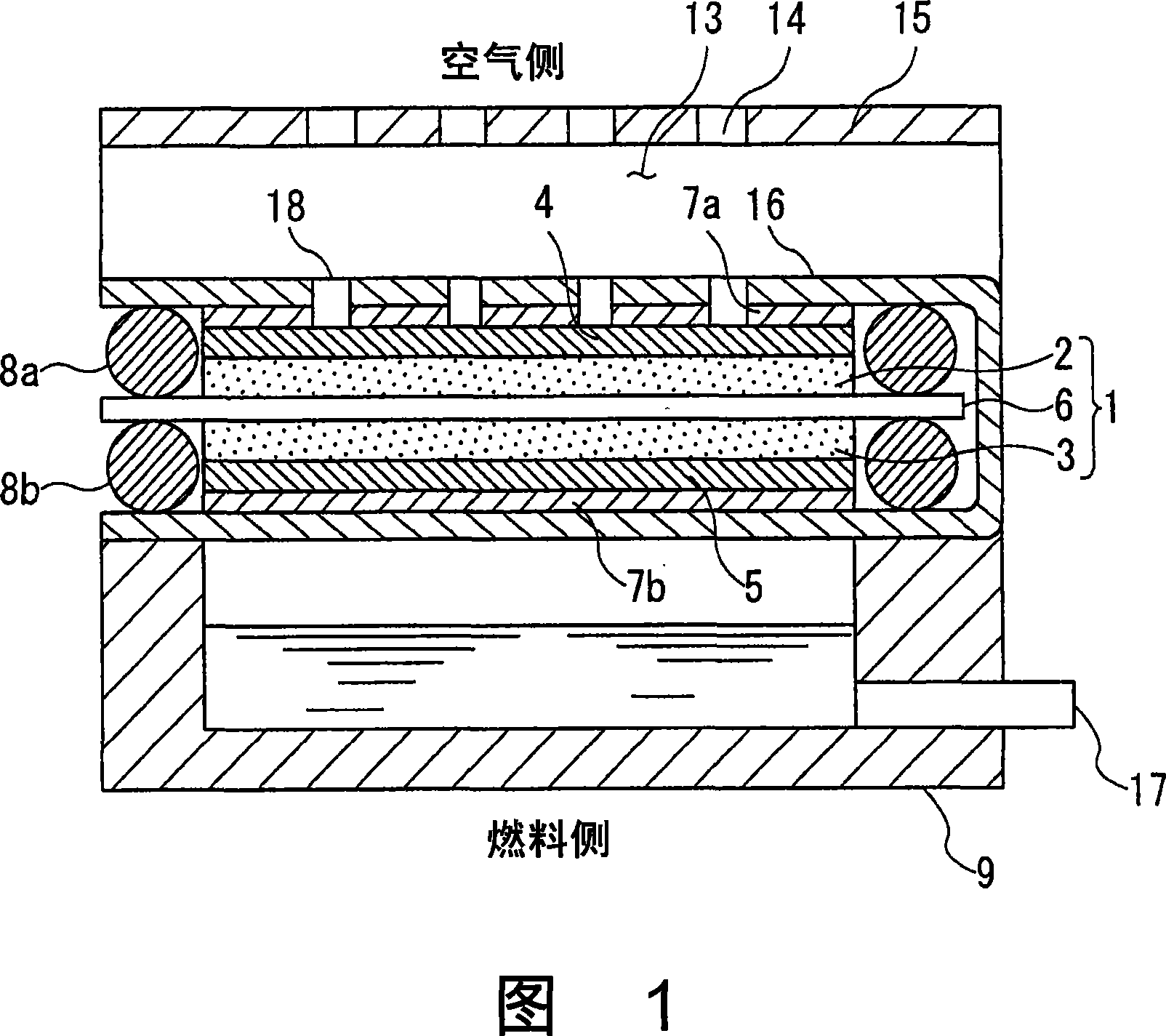

[0066] Add a solution of perfluorocarbon sulfonic acid, water, and methoxypropanol to carbon black loaded with a catalyst for the anode (Pt:Ru=1:1), and prepare a method for dispersing the carbon black loaded with the catalyst for the anode slurry in it. The resulting slurry was coated on porous carbon paper as the anode gas diffusion layer 5, whereby an anode including an anode catalyst layer 3 having a thickness of 450 μm was produced.

[0067]

[0068] A perfluorocarbon sulfonic acid solution, water, and methoxypropanol were added to the carbon black carrying the catalyst (Pt) for the cathode to prepare a slurry in which the carbon black carrying the catalyst for the cathode was dispersed. The resulting slurry was coated on porous carbon paper as the cathode gas diffusion layer 4, thereby producing a cathode including a cathode catalyst layer 2 having a thickness of 400 μm.

[0069] Between the anode catalyst layer 3 and the cathode catalyst layer 2, a perfluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com