Titanium dioxide film for photocatalyst and preparation method thereof

A technology of titanium dioxide and photocatalyst, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of complex preparation process and inability to realize practical application, and achieve simple preparation process, low cost, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

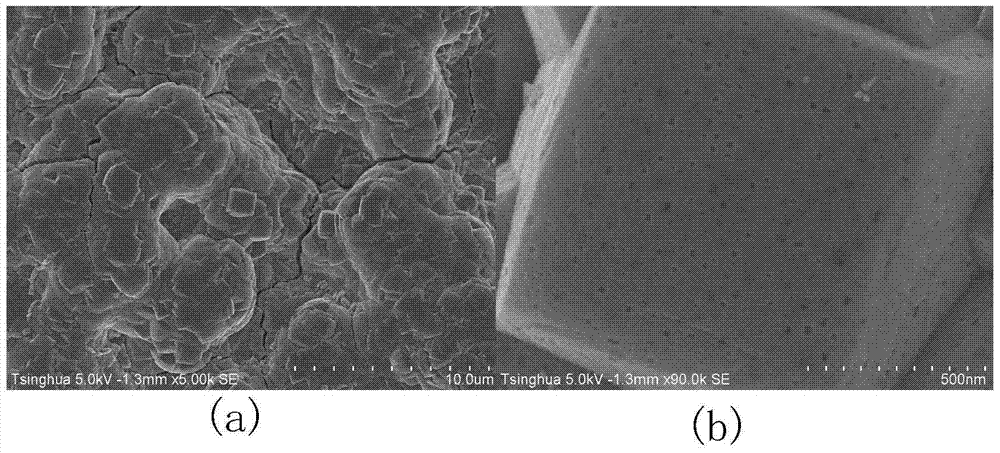

[0042] The titanium sheet (manufactured by Baoji Shengrong Titanium Corporation, purity 99.5%, 240mm×100mm×0.15mm) was ultrasonically cleaned in ethanol to remove organic matter on the surface. Then put the cleaned titanium flakes into a boiling oxalic acid aqueous solution for pretreatment for 0.5 h for etching, and then clean with deionized water and dry. After that, provide a mixed solution of 200 mL of pure water and 200 mL of isopropanol, and then add an aqueous hydrogen fluoride solution to it to make a 0.02 mol / L hydrogen fluoride mixed solution. The total volume of the mixed solution is 400 ml, and then put the titanium sheet and the hydrogen fluoride mixed solution Put it into a 500ml polytetrafluoroethylene reactor, the titanium piece is completely immersed in the hydrogen fluoride mixed solution, hydrothermally reacted at 170℃ for 2h, when the temperature in the reactor returns to room temperature, take out the titanium piece and use it Rinse with ionized water, then...

Embodiment 2

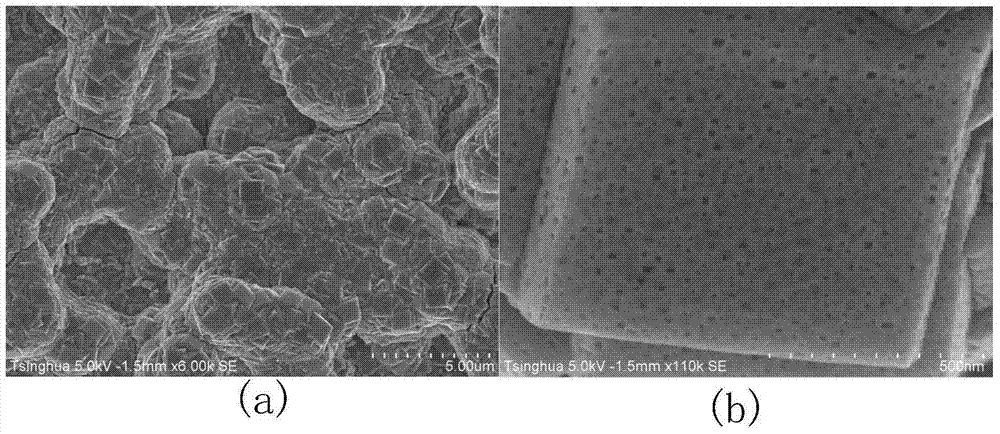

[0045] The titanium sheet (manufactured by Baoji Shengrong Titanium Corporation, purity 99.5%, 240mm×100mm×0.15mm) was ultrasonically cleaned in ethanol to remove organic matter on the surface. The cleaned titanium flakes were put into boiling oxalic acid aqueous solution for pretreatment for 1.5 hours for etching, and then washed with deionized water and dried. After that, provide a mixed solution of 125 mL of pure water and 275 mL of isopropanol, and then add an aqueous hydrogen fluoride solution to it to make a 0.03 mol / L hydrogen fluoride mixed solution, the total volume of the mixed solution is 400 ml, and then put the titanium sheet and the hydrogen fluoride mixed solution Put it into a 500ml polytetrafluoroethylene reactor, the titanium piece is completely immersed in the hydrogen fluoride mixed solution, hydrothermally reacted at 180℃ for 3h, when the temperature in the reactor returns to room temperature, take out the titanium piece and use it Simply rinse with ionized...

Embodiment 3

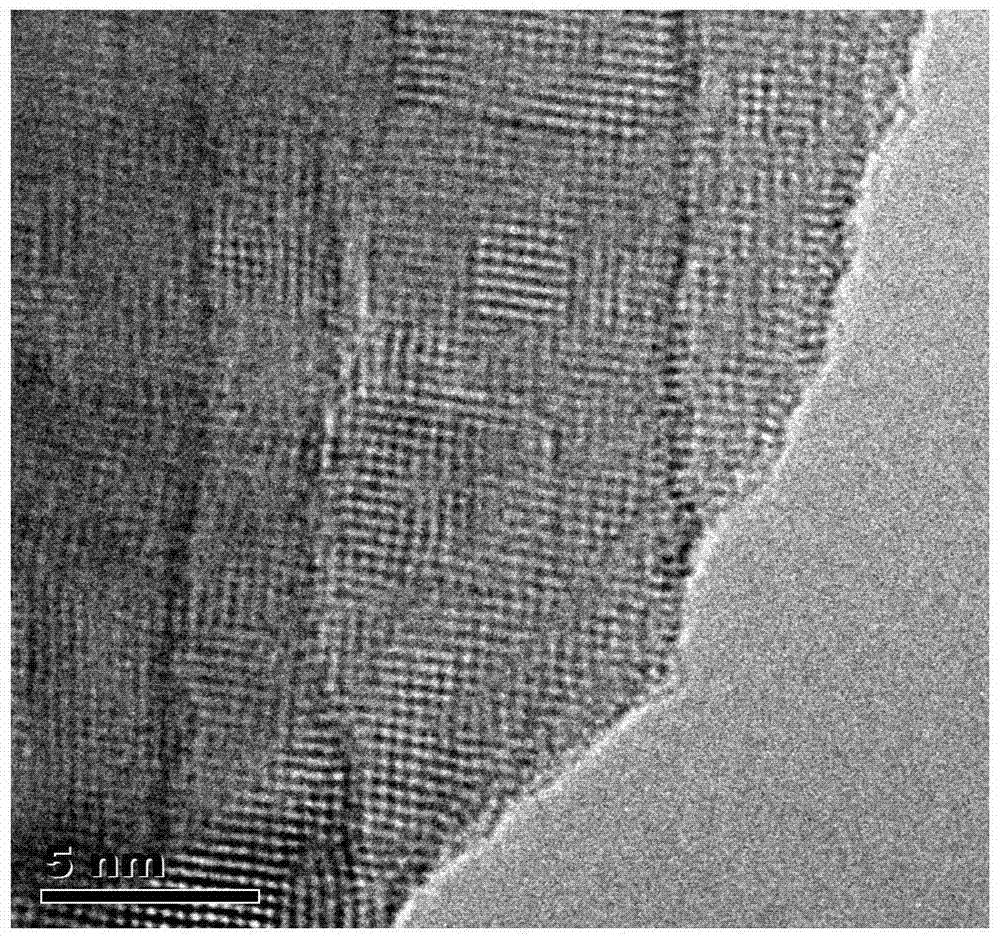

[0050] The titanium sheet (manufactured by Baoji Shengrong Titanium Corporation, purity 99.5%, 240mm×100mm×0.15mm) was ultrasonically cleaned in ethanol to remove organic matter on the surface. The cleaned titanium flakes were put into boiling oxalic acid aqueous solution for pretreatment for 1.5 hours for etching, and then washed with deionized water and dried. After that, provide a mixed solution of 125 mL of pure water and 275 mL of isopropanol, and then add an aqueous hydrogen fluoride solution to it to make a 0.05 mol / L hydrogen fluoride mixed solution, the total volume of the mixed solution is 400 ml, and then put the titanium sheet and the hydrogen fluoride mixed solution Put it into a 500ml polytetrafluoroethylene reactor, the titanium piece is completely immersed in the hydrogen fluoride mixed solution, hydrothermally reacted at 180℃ for 3h, when the temperature in the reactor returns to room temperature, take out the titanium piece and use it Simply rinse with ionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com