A kind of negative electrode material of lithium ion battery and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problem of graphite layer peeling, safety problems, poor cycle life, and graphite interlayer expansion. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

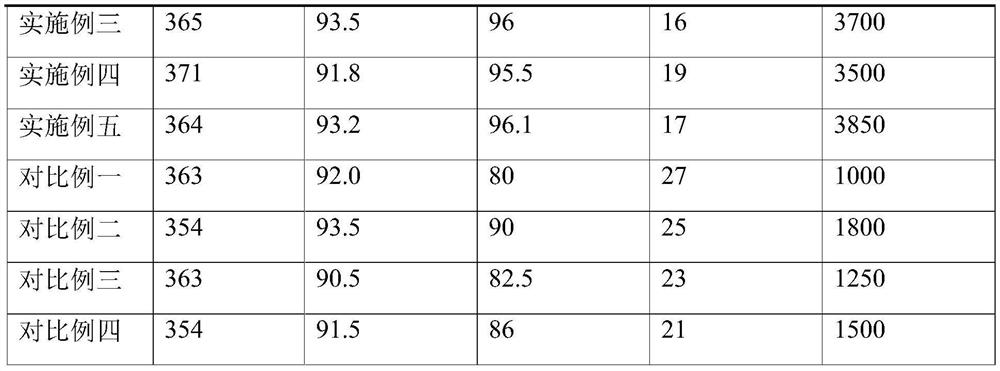

Examples

Embodiment 1

[0041] ①Put 60kg of absolute ethanol into the reaction kettle, choose D50=12μm, specific surface area=7.5m 2 / g, tap density is 0.98g / cm 3 The spherical natural graphite of 40kg is dropped into absolute ethanol, and stirred for 1h to form a uniform slurry. Add 1.2 kg of titanium isopropoxide to the slurry, react at 40° C. for 2 hours while stirring, then wash and filter with ethanol and deionized water in sequence to obtain an intermediate product A.

[0042] ②Put 40 kg of intermediate product A into 60 kg of 10 mol / L sodium hydroxide aqueous solution, react in a reactor at 200° C. for 24 hours, wash and filter with deionized water to obtain solid particle intermediate product B.

[0043]③Put 40 kg of the intermediate product B into 60 kg of 1 mol / L hydrochloric acid solution, react in the reactor at room temperature for 24 hours while stirring, then use deionized water to pH=6.5, filter to obtain solid particles, and dry at 100°C to obtain intermediate Product C.

[0044] ...

Embodiment 2

[0047] ①Put 50kg of absolute ethanol into the reaction kettle, choose D50=8μm, specific surface area=2.5m 2 / g, the tap density is 0.85g / cm 3 50kg of the artificial graphite is dropped into absolute ethanol, stirred for 1h to form a uniform slurry. Add 0.5 kg of titanium isopropoxide to the slurry, react at 35° C. for 1.5 hours while stirring, then wash and filter with ethanol and deionized water in sequence to obtain an intermediate product A.

[0048] ②Put 45 kg of intermediate product A into 55 kg of 10 mol / L sodium hydroxide aqueous solution, react in a reaction kettle at 210° C. for 20 hours, wash and filter with deionized water to obtain solid particle intermediate product B.

[0049] ③ Put 45 kg of the intermediate product B into 55 kg of 1 mol / L hydrochloric acid solution, react in the reactor at room temperature for 20 hours while stirring, then use deionized water to pH = 6.5, filter to obtain solid particles, and dry at 100 ° C to obtain intermediate Product C.

...

Embodiment 3

[0053] ①Put 55kg of absolute ethanol into the reaction kettle, choose D50=8μm, specific surface area=2.5m 2 / g, the tap density is 0.85g / cm 3 artificial graphite, and D50=12μm, specific surface area=7.5m 2 / g, tap density is 0.98g / cm 3 According to the ratio of 6:4, mix the two kinds of graphite, put 50kg of the mixed graphite into absolute ethanol, and stir for 1h to form a uniform slurry. Add 1.0 kg of titanium isopropoxide to the slurry, react at 35° C. for 2 hours while stirring, then wash and filter with ethanol and deionized water in sequence to obtain an intermediate product A.

[0054] ②Put 45 kg of the intermediate product A into 55 kg of 10 mol / L sodium hydroxide aqueous solution, react in the reactor at 210° C. for 24 hours, wash and filter with deionized water to obtain the solid particle intermediate product B.

[0055] ③Put 45 kg of the intermediate product B into 55 kg of 1 mol / L hydrochloric acid solution, react in the reactor at room temperature for 24 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com