Textile winding roller

A technology for textiles and winding rollers, applied in the field of textile winding rollers, can solve the problems of reducing textile quality, reducing textile quality, and textile wrinkles, etc., to achieve good fixation, avoid sliding or wrinkles, and increase winding tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

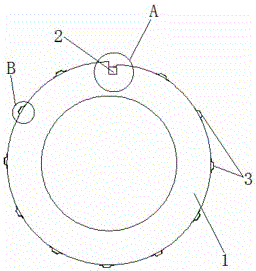

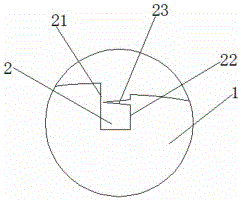

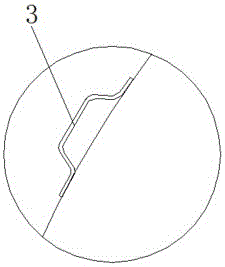

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] Such as Figure 1 to Figure 4 As shown, a textile take-up roll includes a roll body 1, an opening groove 2 is provided on the roll body 1, the opening groove 2 penetrates through the roll body 1 in the axial direction, and the opening groove 2 has a first The groove wall 21 and the second groove wall 22, the distance between the outer edge of the second groove wall 22 and the axis line of the roller body 1 is smaller than the outer edge of the first groove wall 21 and the roller The distance between the axis lines of the body 2, the second groove wall 22 is also provided with a needle part 23, the needle part 23 can pierce the winding start end of the textile 4, and the outer peripheral surface of the roller body 1 is along the A plurality of shrapnels 3 are evenly distributed in the circumferential direction, and the length of each shrapnel 3 along the axial direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com