Working roll replacement auxiliary device of rough mill and roll replacement method of working roll replacement auxiliary device

A technology of auxiliary devices and work rolls, applied in metal rolling stands, metal rolling mill stands, metal rolling and other directions, can solve the problems of uneven wear and waste more time, and achieve easy operation, simple replacement steps, The effect of meeting customer needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples of the present invention are described with reference to specific implementations, and the examples are only used to explain the present invention, and should not be construed as limiting the present invention.

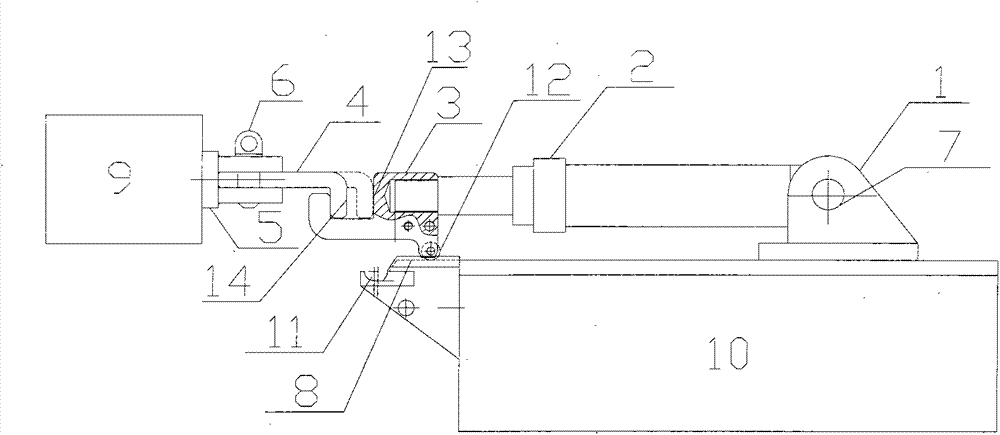

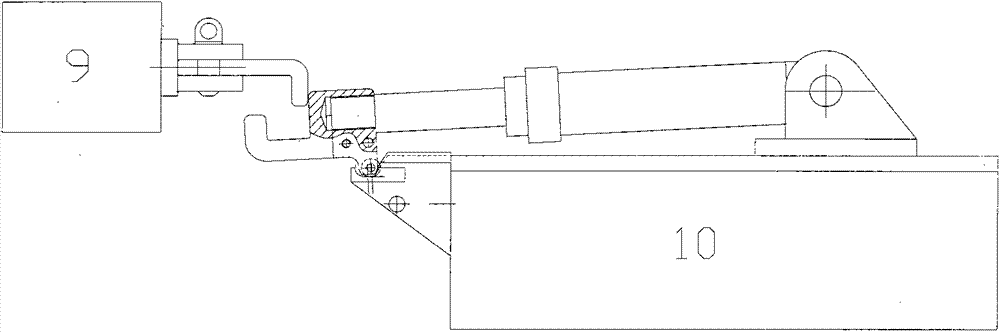

[0020] Such as figure 1 , figure 2 As shown, a 650 rough rolling mill work roll changing auxiliary device, the device is composed of an oil cylinder base 1, a hydraulic cylinder 2 with a stroke of 350 mm, a first hook body 3, a second hook body 4, a hook seat 5, a first pin Shaft 6, the second bearing pin 7, track 8 and other structural components.

[0021] Oil cylinder base 1 is the main fulcrum of carrying oil cylinder (hydraulic cylinder 2), and this oil cylinder base 1 is fixed on the rear shaft holder frame 10 of the transmission side machine, with a steel plate attached at the bottom, integrally welded. The cylinder body of the oil cylinder is hinged on the oil cylinder base 1 through the first bearing pin 6, and the oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com